Vacuum incinerator device and operating method thereof

An incinerator and vacuum technology, applied in the direction of furnace control devices, furnaces, furnace types, etc., can solve the problems of inconvenient opening and closing of the furnace, insufficient automation control, inaccurate temperature control, etc., and achieve compact structure, good sealing, and high temperature Control precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

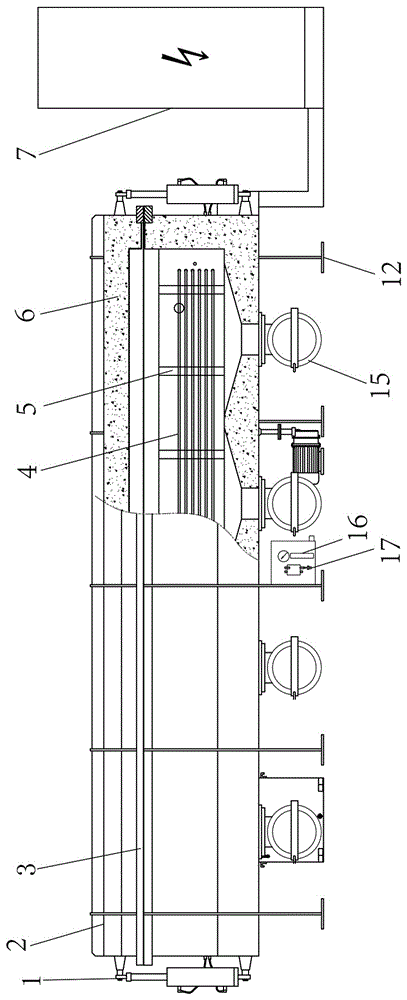

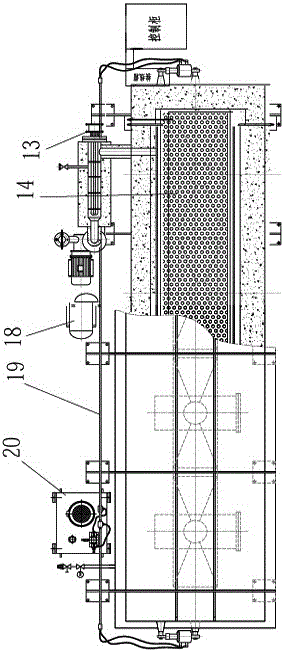

[0053] Using the vacuum incinerator in the above embodiment, the size of the working chamber in the furnace is 4000mm×550mm×450mm, the maximum load in the furnace is 1500Kg, the maximum working design temperature is 600°C, and it can be precisely adjusted at 0-450°C. The total power: 54.1Kw, of which Heating power 45Kw, water ring vacuum pump motor power 4.0Kw, anti-blocking material heating power 4.0Kw, furnace lid opening and closing hydraulic pump station power 1.1Kw, vacuum degree: -0.065~-0.085MPa, furnace lid opening angle: 92°~ 95°, temperature control accuracy: ±1°C,.

Embodiment 2

[0055] The vacuum incinerator in this embodiment, its vacuum: -0.065 ~ -0.085MPa, water consumption: ≤0.4m 3 / h, power supply: 380V, 50Hz, three-phase five-wire, temperature control accuracy: ±0.5°C, and others are the same as in Embodiment 1.

Embodiment 3

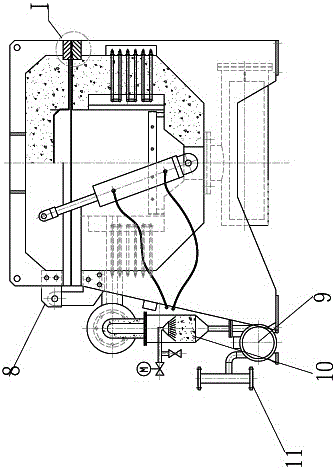

[0057] 1. Put the parts to be cleaned into the furnace, close the furnace cover, and the cleaning parts are made of polyester.

[0058] 2. According to the characteristics of the parts to be cleaned, set the program temperature controller according to the following temperature control curve, turn on the heating switch, and the equipment will enter the automatic operation state. The heating and cooling process of the incineration and cleaning are as attached Figure 4 The time-temperature curve in the medium is shown as:

[0059] A. Heating stage: room temperature to 300°C, 1 hour.

[0060] B. Melting stage: 300°C, 3 hours.

[0061] C, D Cracking stage: 300~450℃, 5.5 hours (including 2 hours of oxidation stage).

[0062] E. Oxidation stage: 450°C, 2 hours, at this point the cleaning procedures are all over.

[0063] F, natural cooling stage.

[0064] After the end of stage A, the vacuum pump is turned on, the water inlet solenoid valve is automatically opened until the end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com