Incinerator

A waste incinerator and furnace wall technology, applied in the field of incinerators, can solve the problems of single function, secondary pollution, incomplete combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

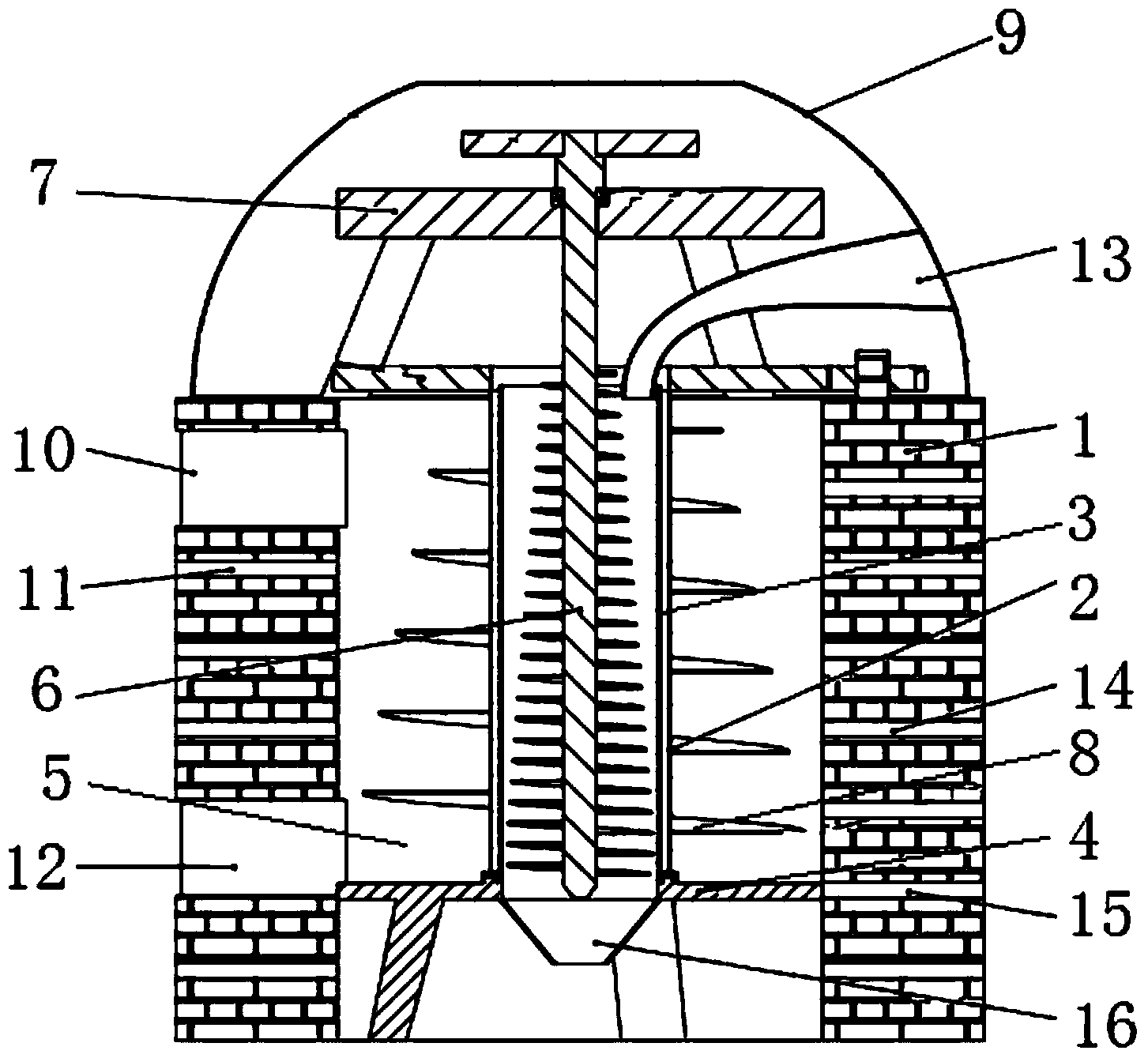

[0018] A garbage incinerator includes an outer furnace wall 1, an outer furnace core 2 and an inner furnace core 3 arranged in sequence from the outside to the inside. The outer furnace core 2 and the inner furnace core 3 are fixed on a base 4, and the base 4 The outer furnace wall 1 and the outer furnace core 2 form an outer furnace cavity 5 for burning garbage. A pallet 7 is provided on the top of the outer furnace wall 1, and a garbage inlet 10, a fuel input channel 11 and an oxygen input channel 14 are arranged on the upper part of the outer furnace wall 1. A feeder 8 is provided between the outer furnace core 2 and the outer furnace wall 1, a feed inlet 13 is provided on the upper part of the inner furnace core 3, and a stirrer 6 is provided in the inner furnace core 3. The outer furnace cavity 5 can be used for incineration of garbage, and the inner furnace core 3 can be used for roasting chemical waste that can be converted into ceramic raw materials. The temperature gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com