Sludge steam conditioning and high-dryness dewatering coupled incineration integrated method and device

A steam and sludge technology, which is applied in combustion methods, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of high operating cost and large investment, and achieve the reduction of investment cost and operating cost, and large investment , The effect of high calorific value of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

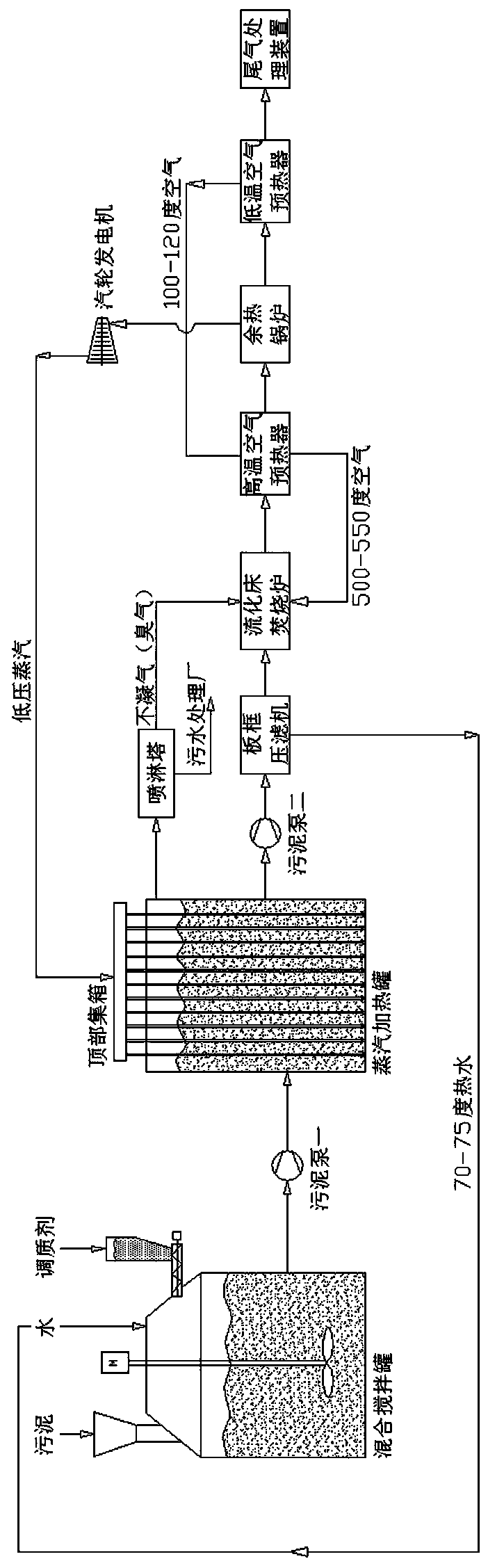

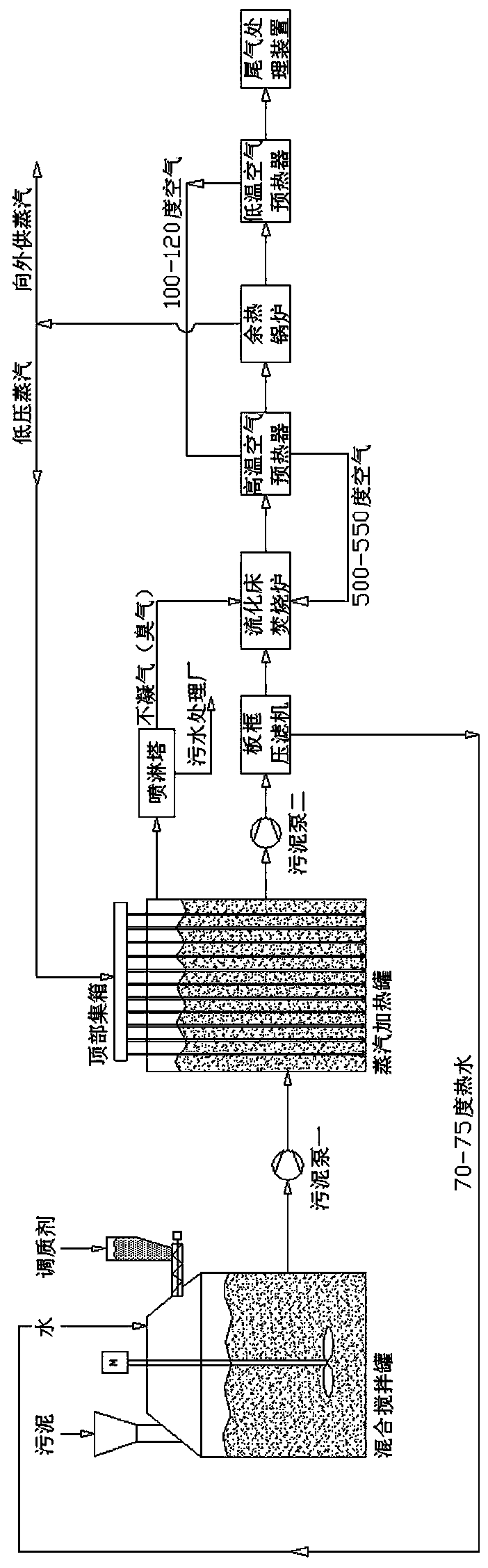

[0010] refer to figure 1 with figure 2 , an integrated method of sludge steam conditioning, high drying, dehydration, coupled incineration, which includes adding sludge with a moisture content of 80%, water and conditioning agent PAM1-2%tDS or PAC4-5%tDS into a mixing tank and stirring evenly , to obtain sludge with a moisture content of 90%, and then send the sludge with a moisture content of 90% to a steam heating tank for heating to 90-100°C, and then send the sludge with a moisture content of 90% at 90-100°C to high pressure The plate and frame filter press presses and dehydrates under the pressure of 5.0MPa to obtain a sludge filter cake with a moisture content of 30-35%; finally, the sludge filter cake with a moisture content of 30-35% is crushed and sent to a fluidized bed for incineration Self-sustaining combustion in the furnace.

[0011] A sludge steam conditioning high-drying dehydration coupled incineration integrated device, which includes a mixing tank, a stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com