Drying incineration process of urban domestic sludge

A technology for drying municipal domestic sludge, which is applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of high energy consumption, high operating costs, and low calorific value of urban sludge on a dry basis, so as to reduce energy consumption and The effect of operating cost, high calorific value, high application value and economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

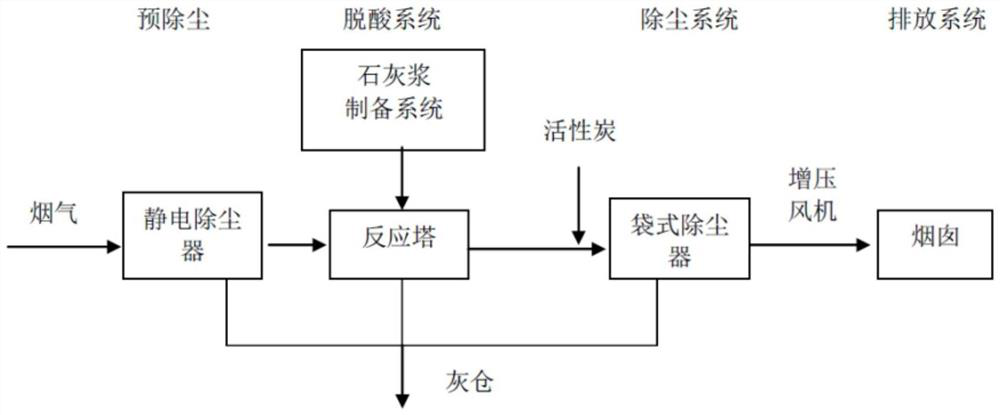

Image

Examples

Embodiment 1

[0031] Embodiment 1 A kind of dry incineration process of municipal domestic sludge

[0032] The dry incineration process specifically includes the following steps:

[0033] (1) In the summer, 600t of wet sludge was collected from the sewage plant in the central city of Guangzhou, with a moisture content of 80% and a low calorific value of 1700kcal / kg on a dry basis. The collected sludge was dried in a sludge dryer to Moisture content is 65%;

[0034] (2) 6 t of Taibai flower residues were collected from a pharmaceutical factory in Guangzhou; the collected Taibai flower residues were dried to a moisture content of 40%;

[0035] (3) Mix the dried sludge in step S1 with the dried Taibai flower dregs in step S2 to form a mixed material, and the dry basis calorific value of the mixed material measured by an automatic calorimeter (IKA-CA000) is 3700kcal / kg, crushed to 40 mesh by the crusher, then sent to the bubbling fluidized bed incinerator for incineration, the incineration t...

Embodiment 2

[0037] Embodiment 2 A kind of dry incineration process of municipal domestic sludge

[0038] The dry incineration process specifically includes the following steps:

[0039] (1) In winter, 600t of wet sludge was collected from the sewage plant in the central urban area of Guangzhou, with a moisture content of 80% and a low calorific value of 2700kcal / kg on a dry basis. The collected sludge was dried in a sludge dryer to Moisture content is 55%;

[0040] (2) Collect 4t of notoginseng dregs from a pharmaceutical factory in Guangzhou; dry the collected notoginseng dregs to a moisture content of 30%;

[0041] (3) The sludge dried in step S1 is mixed with the dried Taibai flower dregs in step S2 to form a mixed material, and the dry basis calorific value of the mixed material measured by an automatic calorimeter (IKA-CA000) is 3850kcal / kg, after being crushed to 80 mesh by a crusher, it is transported to a bubbling fluidized bed incinerator for incineration. The mixed material c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com