Oxygen-enriched burning device burning inferior coal

A technology of oxygen-enriched combustion and low-quality coal, which is applied in the direction of combustion methods, combustion equipment, and non-flammable liquid/gas transportation, etc. It can solve the problems of poor adaptability of coal types, single oxygen-enriched channels, and research on the use of low-quality coal for oxygen-enriched combustion There are fewer problems, and it is convenient to replace equipment, save money, and shorten the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

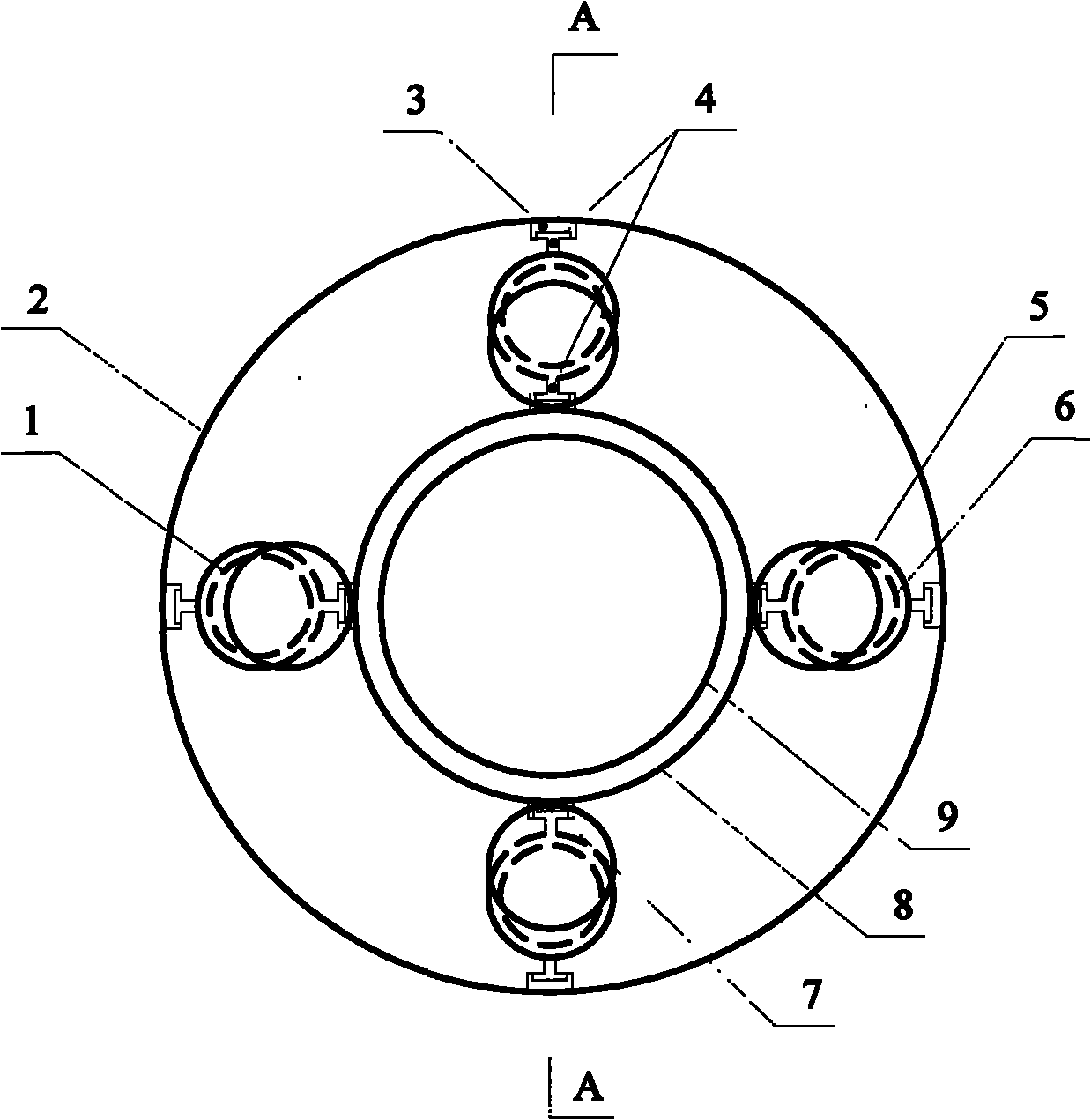

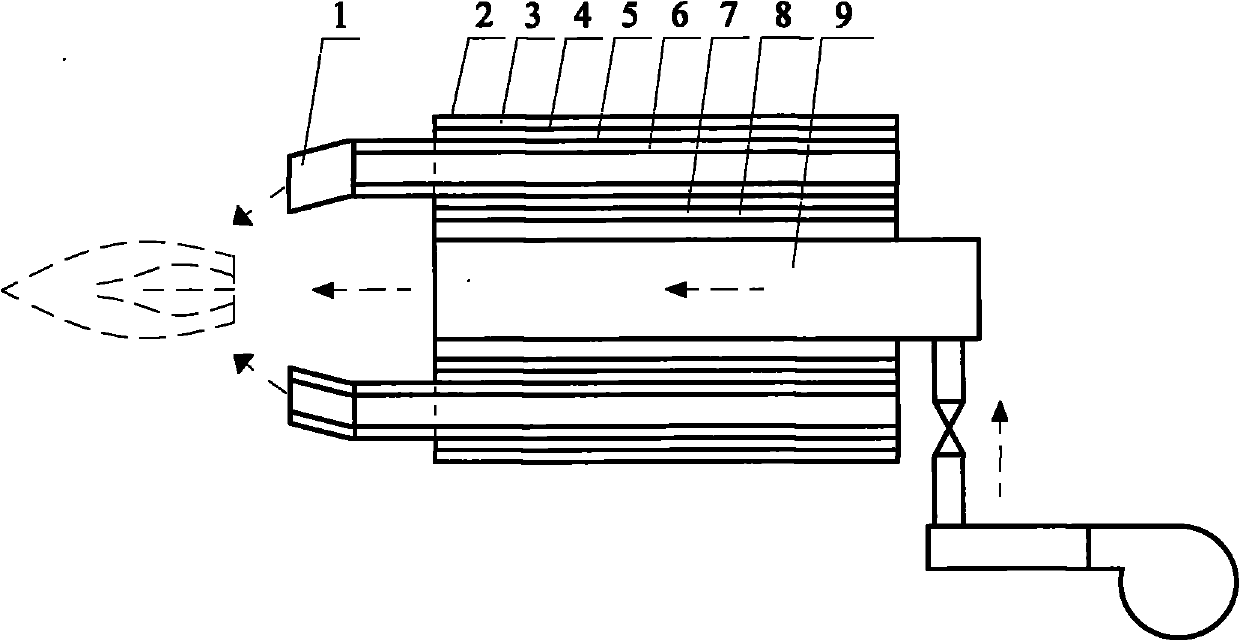

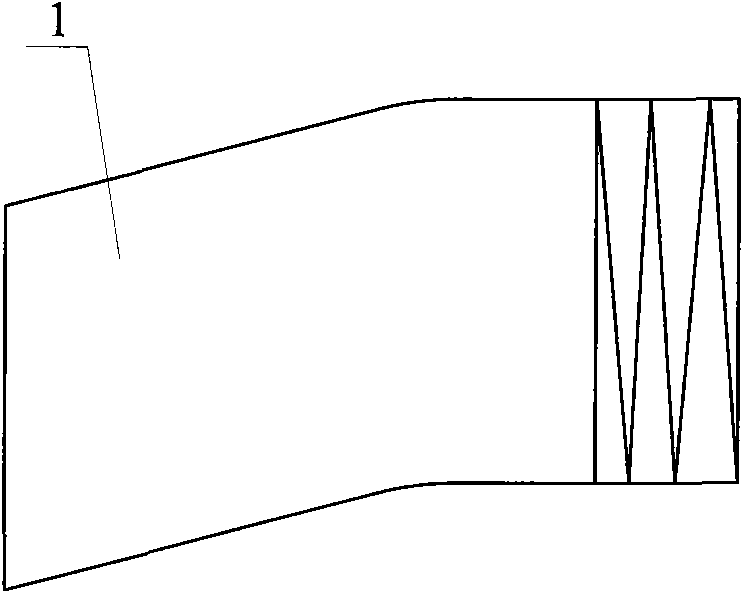

[0018] figure 1 It is a schematic diagram of the oxygen-enriched combustion device involved in the present invention, and the oxygen-enriched combustion device includes an oxygen-enriched nozzle 1, an outer casing 2, a sliding device, an oxygen-enriched channel, an inner sleeve 8 and a combustion component 9; the combustion component 9. The inner casing 8 and the outer casing 2 are arranged concentrically, the combustion part 9 is arranged inside the inner casing 2, and from the inside to the outside are the combustion part, the inner casing and the outer casing. Combustion part 9 can adopt conventional burner, and air and pulverized coal are sprayed into from this burner. The oxygen-enriched channel is composed of a heat-resistant tube 5 and a ceramic tube 6 arranged inside the heat-resistant tube. The oxygen-enriched channel is nested and fixed in the sliding device, and can be moved along the inner sleeve 8 and the outer sleeve 2. Sliding in the direction of the central ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com