Harmless treatment method of gold cyanidation tailings highly containing arsenic

A technology of harmless treatment and cyanidation of tailings, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as low recovery rate, environmental pollution, and inability to obtain qualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

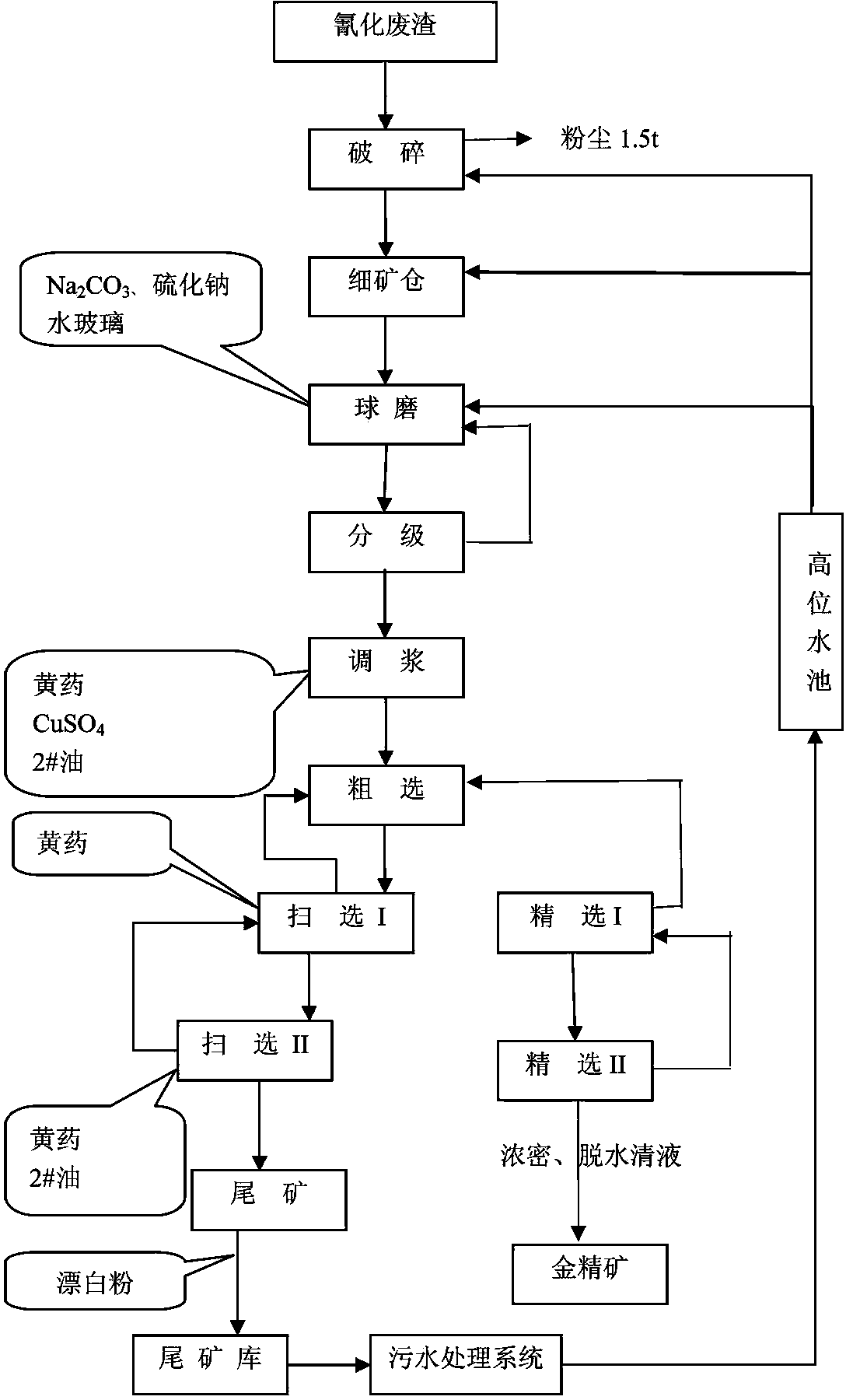

[0017] Such as figure 1 Shown, a kind of high arsenic-containing gold cyanide tailings harmless treatment method of the present invention comprises the following steps:

[0018] 1) Crushing: crush the gold cyanide tailings twice with a crusher, so that the particle size of the gold cyanide tailings is not greater than 10mm;

[0019] 2) Grinding: Send the crushed gold cyanide tailings into a ball mill, and add sodium carbonate, sodium sulfide, water glass and an appropriate amount of water into the ball mill for grinding, wherein the amount of sodium carbonate added is 1000g / t, sodium sulfide The addition amount of water glass is 200g / t, the addition amount of water glass is 100g / t, and the addition amount of water should make the grinding concentration reach 70%;

[0020] 3) Classification: The ground cyanide tailings are sent to the classifier for classification, and the coarse particles at the back end of the classifier are returned to the ball mill for regrinding. When th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com