Process for capturing rubbish landfill gas carbon dioxide

A landfill gas and carbon dioxide technology, applied in indirect carbon dioxide emission reduction, chemical industry, liquefaction, etc., can solve the problems of high absorbent regeneration temperature, pollution, chemical absorbent leakage or volatilization environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

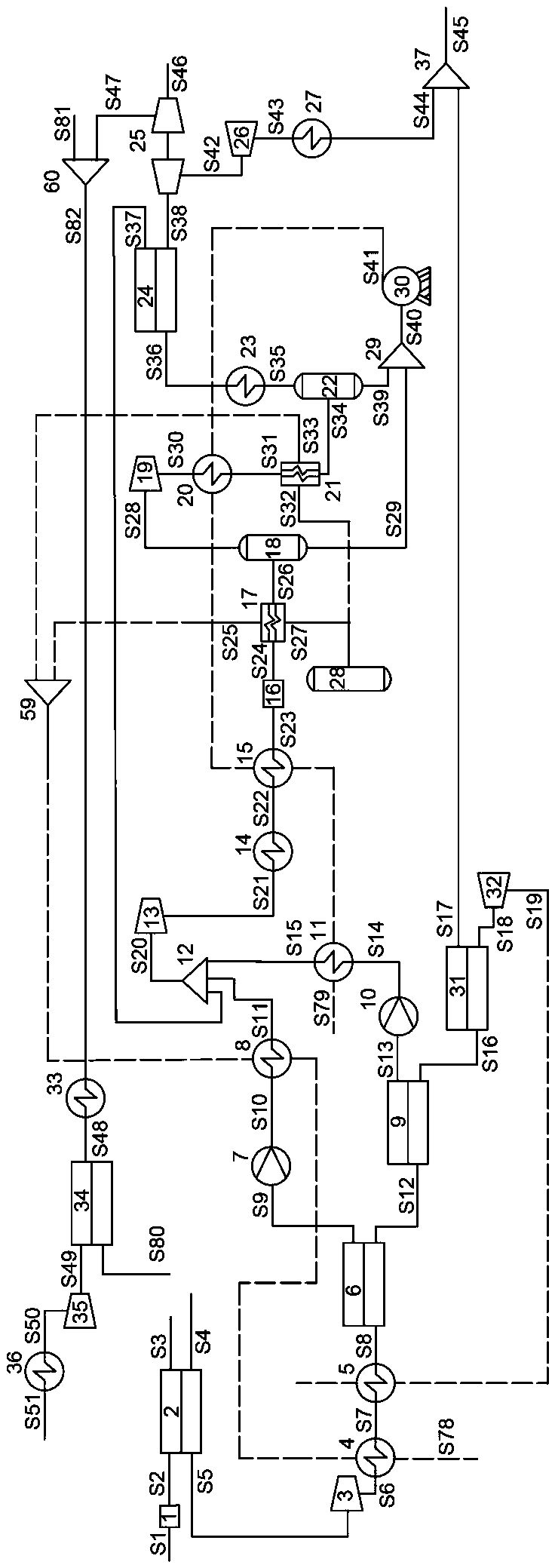

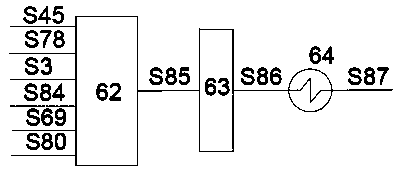

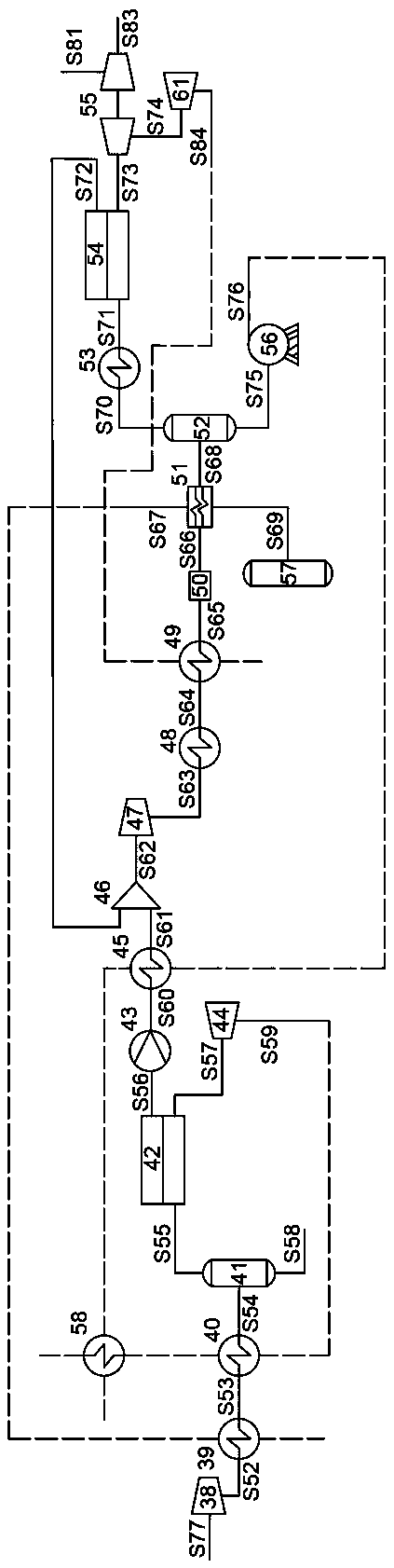

[0018] A landfill gas carbon dioxide capture process of the present invention includes a landfill gas decarbonization and oxygen enrichment section, a landfill gas combustion link, and a flue gas carbon dioxide capture section after landfill gas combustion; in order to better illustrate the present invention The existing technical solutions will be described in detail below in conjunction with the drawings required in the description of the existing technical solutions.

[0019] refer to figure 1 , The landfill gas decarbonization and oxygen-enrichment section of the present invention can be divided into membrane module decarbonization and oxygen-enrichment link, three-stage membrane separation link, two-step low-temperature cryogenic separation link, carbon dioxide capture and reflux link, and membrane module oxygen-enrichment link.

[0020]The landfill gas enters the capture system from S1, first passes through the garbage into landfill gas purification device 1, and then pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com