Low-carbon method for improving emission reduction efficiency of oxynitride in circulated flue gas from sintering machine

A technology of nitrogen oxides and flue gas circulation, which is applied in the field of sintering flue gas nitrogen oxides emission reduction and sintering flue gas circulation nitrogen oxides (NOx) emission reduction, can solve the problem of flue gas temperature changes, large fluctuations, Problems such as complex flue gas components of sintering machines can achieve the effect of increasing energy consumption and operating costs, increasing equipment and construction investment, and strengthening the effect of NOx emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

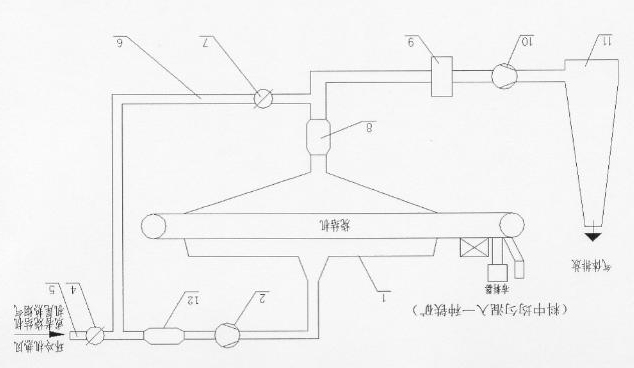

[0027] see figure 1 , the present invention provides a low-carbon method for improving the emission reduction efficiency of sintering machine flue gas circulation nitrogen oxides, comprising the following steps:

[0028] (1) Extract the flue gas in the middle of the total flue gas from the main flue for flue gas circulation;

[0029] (2) Add the iron ore catalyst evenly into the sintering auxiliary materials.

[0030] The oxygen content in the flue gas in the upper circulation hood of the sintering trolley should not be lower than 18%, and the maximum circulation volume should be 50%.

[0031] The implementation mode of this embodiment is as follows:

[0032] Such as figure 1 As shown, the numbers in the figure: 1 is the upper smoke hood, 2 is the circulating fan, 4 is the air mixing regulating valve, 5 is the air mixing regulating pipe, 6 is the circulating pipe, 7 is the damper valve, 8 is the main dust collector, 9 10 is a blower fan, 11 is a chimney, and 12 is a coarse...

Embodiment 2

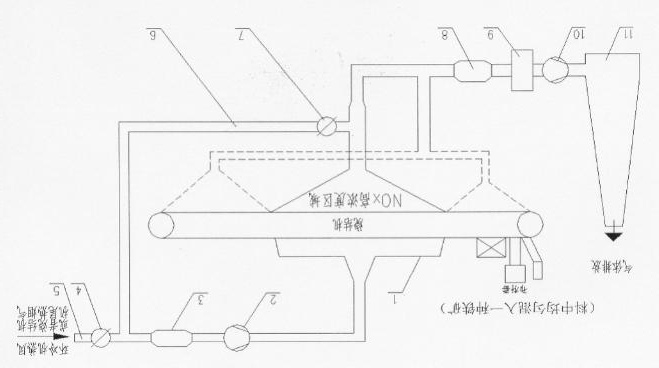

[0036] see figure 2 , the present invention provides a low-carbon method for improving the emission reduction efficiency of sintering machine flue gas circulation nitrogen oxides, comprising the following steps:

[0037] (1) Extract smoke from the area between 20% and 70% of the nose to the tail for smoke circulation;

[0038] (2) The iron ore is evenly mixed into the sintering auxiliary material as a catalyst.

[0039] The oxygen content in the flue gas in the upper circulation hood of the sintering trolley should not be lower than 18%, and the maximum circulation volume should be 50%.

[0040] The implementation mode of this embodiment is as follows:

[0041] Such as figure 2 As shown, the numbers in the figure: 1 is the upper smoke hood, 2 is the circulating fan, 3 is the circulating dust collector, 4 is the mixing air regulating valve, 5 is the mixing air regulating pipe, 6 is the circulating pipe, 7 is the baffle valve, 8 9 is a desulfurization device, 10 is a fan, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com