Starting emission reduction method for ethene device

An ethylene device, ethylene propylene technology, applied in the direction of ethylene production, petroleum industry, hydrogenation process, etc., can solve the waste of materials, prolong the start-up time, danger and other problems, to avoid the risk of leakage, prolong the start-up time, improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

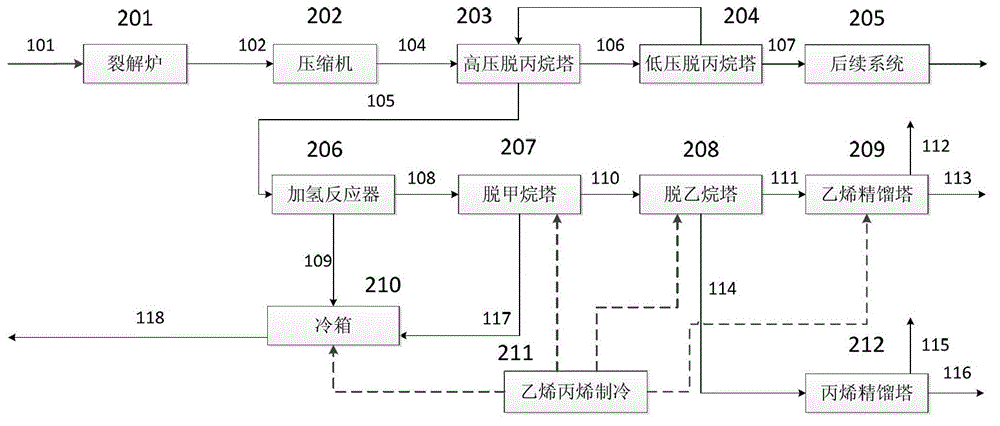

[0045] The following is an example of an ethylene unit that was hydrogenated before the previous depropanization process. The specific process flow of the ethylene unit is as follows:

[0046] Such as figure 1 As shown, the cracking furnace feed 101 (usually including naphtha, light hydrocarbons and hydrogenated tail oil) enters the cracking furnace 201, and the generated cracked gas 102 is compressed by the compressor 202, enters the high-pressure depropanizer 203, and the low-pressure depropanizer Tower 204. In this system, the cracked gas is divided into carbon three and below components and carbon four and above components.

[0047] C4 and above components in the bottom of the low-pressure depropanizer 204 enter the follow-up system 205 for further separation.

[0048] The C3 and lower components 105 at the top of the high-pressure depropanizer 203 enter the hydrogenation reactor 206 to selectively hydrogenate alkynes and diolefins below C3 to form monoolefins 108, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com