Circulation novel process for preparing white carbon black

A technology of white carbon black and new process, which is applied in the field of new circular process for preparing white carbon black, can solve the problems of environmental pollution, consumption of large energy, protection of unfavorable ecological environment, etc., and achieves high utilization rate, reduction of production cost, improvement of The effect of recycling value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

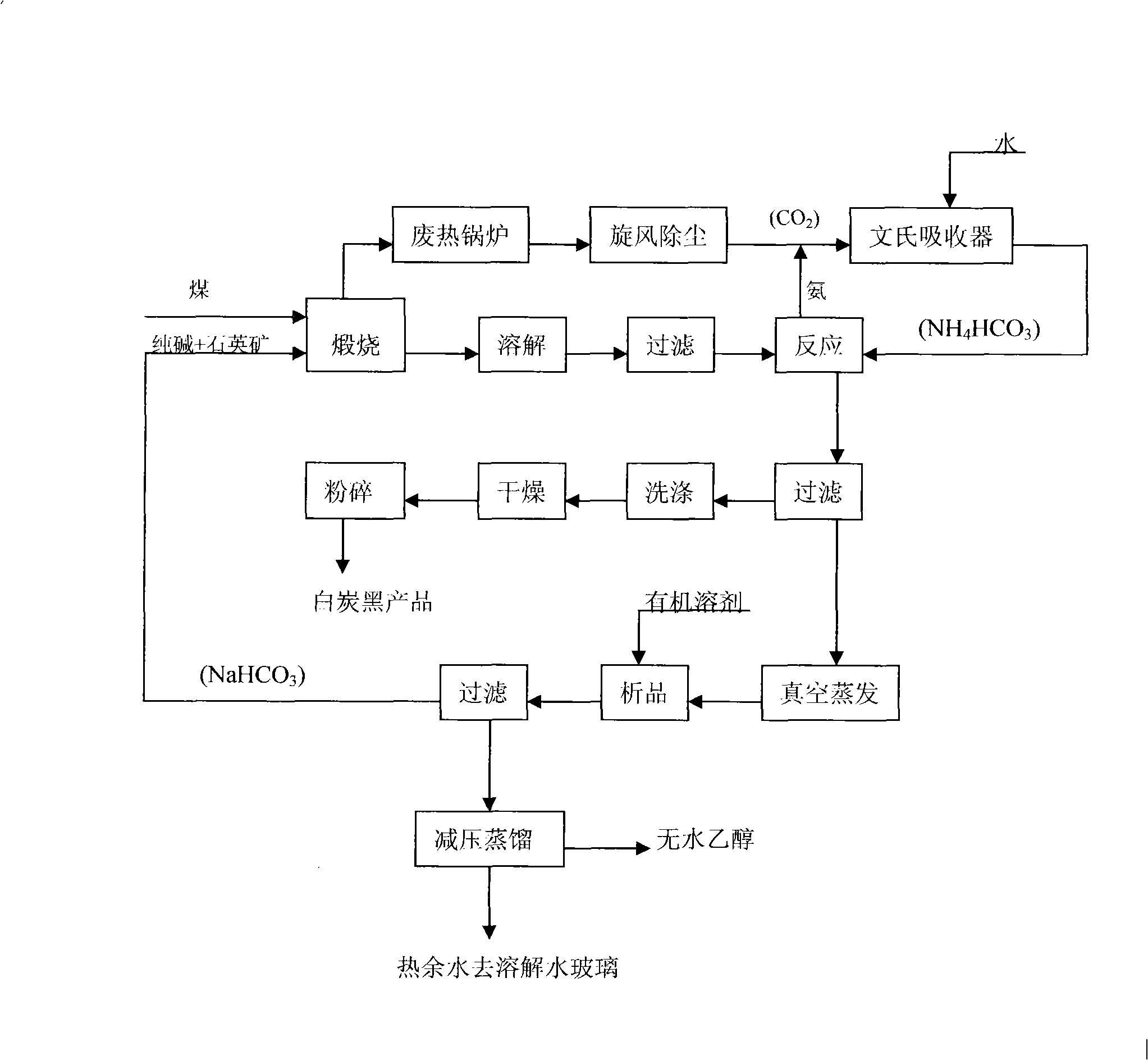

[0018] Such as figure 1 Add 300ml of water glass with a modulus of 3.2 to a dilute solution of 10°Be' after purification and add it to a 1000ml stirred reactor, keep the reaction material at 45°C, and add 20g of refined NH 4 HCO 3 , so that it undergoes the following reaction: Na 2 O mSiO 2 +2NH 4 HCO 3 =2NaHCO 3 +mSiO 2 ·nH 2 O↓+2NH 3 ↑+(1-mn)H 2 O, where water glass solution and NH 4 HCO 3 The molar ratio is controlled at 1:2.0~1:2.2 (among which 3.1<m<3.4), after 45-60 minutes of reaction, the gas escaping from the top of the reactor can not smell ammonia smell (it can be checked by wet test paper), then the reaction is over , to obtain loose precipitated silica.

[0019] The precipitate that above-mentioned reaction is made is filtered under vacuum condition, obtains filter cake first and mother liquor first, after initial mother liquor first evaporates 1 / 3 moisture through vacuum low temperature, the mass concentration that makes sodium bicarbonate in mother l...

Embodiment 2

[0022] Such as figure 1 Add 300ml of water glass with a modulus of 3.2 to a 9°Be′ dilute solution after purification and add it to a 1000ml stirred reactor, keep the reaction material at 30°C, and add 19g of refined NH 4 HCO 3 , so that it undergoes the following reaction: Na 2 O mSiO 2 +2NH 4 HCO 3 =2NaHCO 3 +mSiO 2 ·nH 2 O↓+2NH 3 ↑+(1-mn)H 2 O, where water glass solution and NH 4 HCO 3 The molar ratio is controlled at 1:2.0~1:2.2 (among which 3.1<m<3.4), after 45-60 minutes of reaction, the gas escaping from the top of the reactor can not smell ammonia smell (it can be checked by wet test paper), then the reaction is over , to obtain loose precipitated silica.

[0023] The precipitate that above-mentioned reaction is made is filtered under vacuum condition, obtains filter cake first and mother liquor first, after initial mother liquor first evaporates 1 / 3 moisture through vacuum low temperature, the mass concentration that makes sodium bicarbonate in mother liquo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com