Cable-stayed bridge construction method

A construction method and technology of cable-stayed bridges, applied to cable-stayed bridges, bridges, bridge parts, etc., can solve problems such as reducing the economy of bridge construction, restricting the development of long-span bridges, and increasing the load of towers and anchorages, etc., to achieve Avoid the instability of large cantilever, reduce the difficulty of implementation, and optimize the effect of beam section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

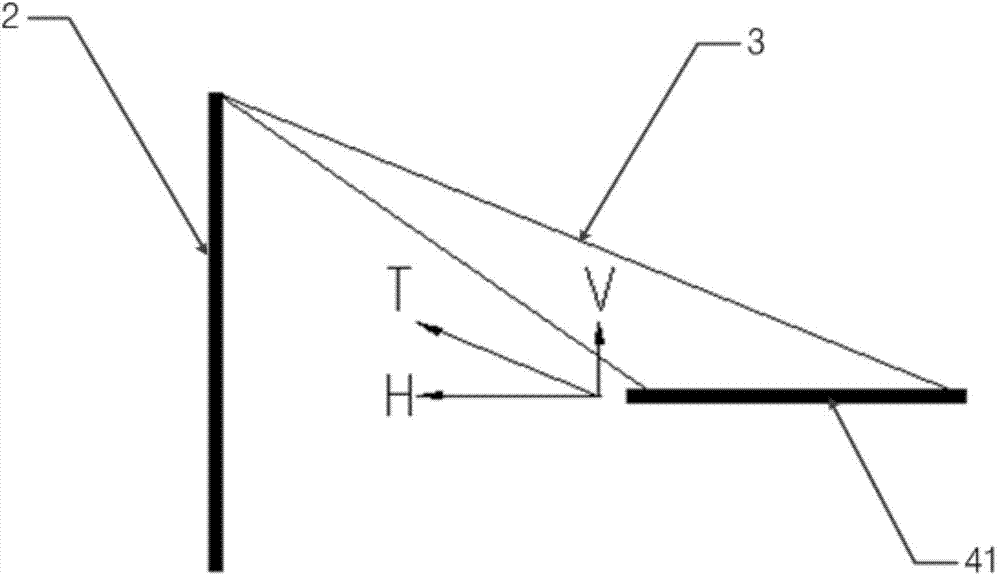

[0052] figure 1 Shows the force diagram of a beam section in a cable-stayed bridge, where the cable 3 connecting the beam section 41 is slanted to the pylon 2, the beam section 41 is subjected to the pulling force T of the cable 3, and the pulling force T can be decomposed into horizontal direction The force H and the vertical force V. When the traditional construction method is adopted, that is, the main girder of the cable-stayed bridge is installed from near the tower to the mid-span, the force H accumulates as the length of the main girder installation increases, that is, the continuous accumulated compressive stress is formed on the main girder, and the design must be large enough In order to ensure the rigidity of the main beam, the span of the bridge is restricted. In the construction method of the present invention, the remote tower is installed first, and the load is transferred to the tower through the cable. The opposite force on the other side of the tower and beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com