High Purity Heavy Normal Paraffins Utilizing Integrated Systems

a technology of integrated systems and heavy normal paraffin, applied in the direction of hydrocarbon oil treatment products, hydrocarbon distillation, aromatic hydrocarbon hydrogenation, etc., can solve the problems of inconvenient adsorption separation, expensive equipment, and equipment is not readily replaced, so as to improve the purity of a normal paraffin stream, reduce contaminants, and reduce the concentration of heavy aromatics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

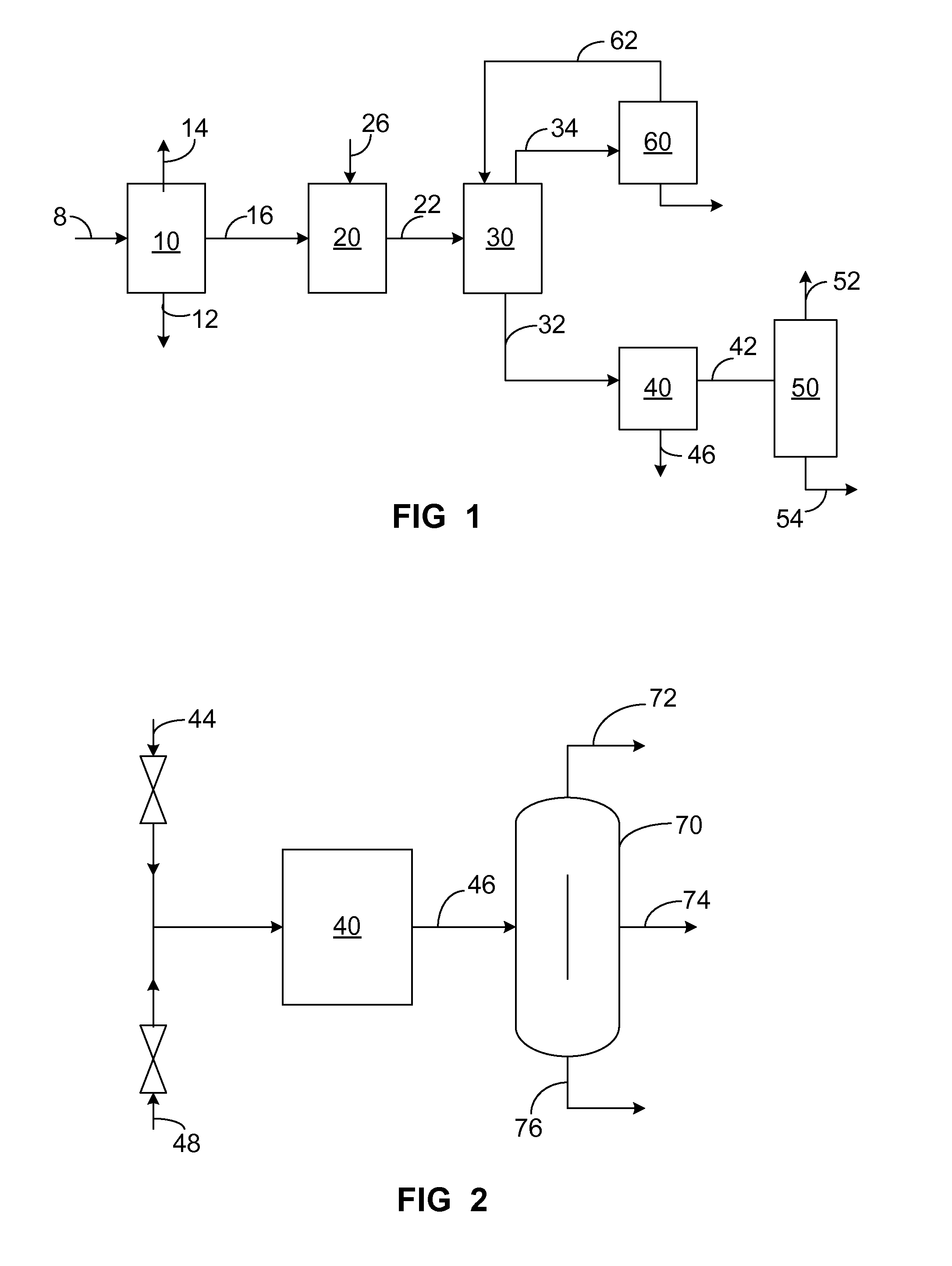

[0010]A high purity heavy normal paraffin is required for some applications. The high purity, also includes having a low aromatic content. Conventional methods for producing a heavy normal paraffin result in a product that contains an aromatic content greater than 0.5% by weight. The high purity heavy normal paraffins require a purity of greater than 99.5 wt. % with an aromatic content less than 100 ppm by weight. Conventional methods use a high pressure hydrogenation process to saturate the aromatics, but this does not increase the overall purity of the heavy normal paraffin.

[0011]Linear alkylbenzenes (LABs) and secondary alkane sulfonates (SASs) are types of surfactant components used for the production of detergents. The production of LABs requires a feedstream of linear olefins, which in turn can be produced from linear paraffins. The linear olefins useful for producing SASs for detergent production have linear carbons chains in the 10 to 20 range, and preferably in the 14 to 17...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| movement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com