Continuous stripping process and device for chlorinated paraffin

A chlorinated paraffin and process technology, which is applied in the field of chlorinated paraffin continuous blow-off process and its devices, can solve the problems of many sets of equipment, low degree of automation, and large amount of nitrogen gas, so as to improve the level of automation and improve the utilization rate , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

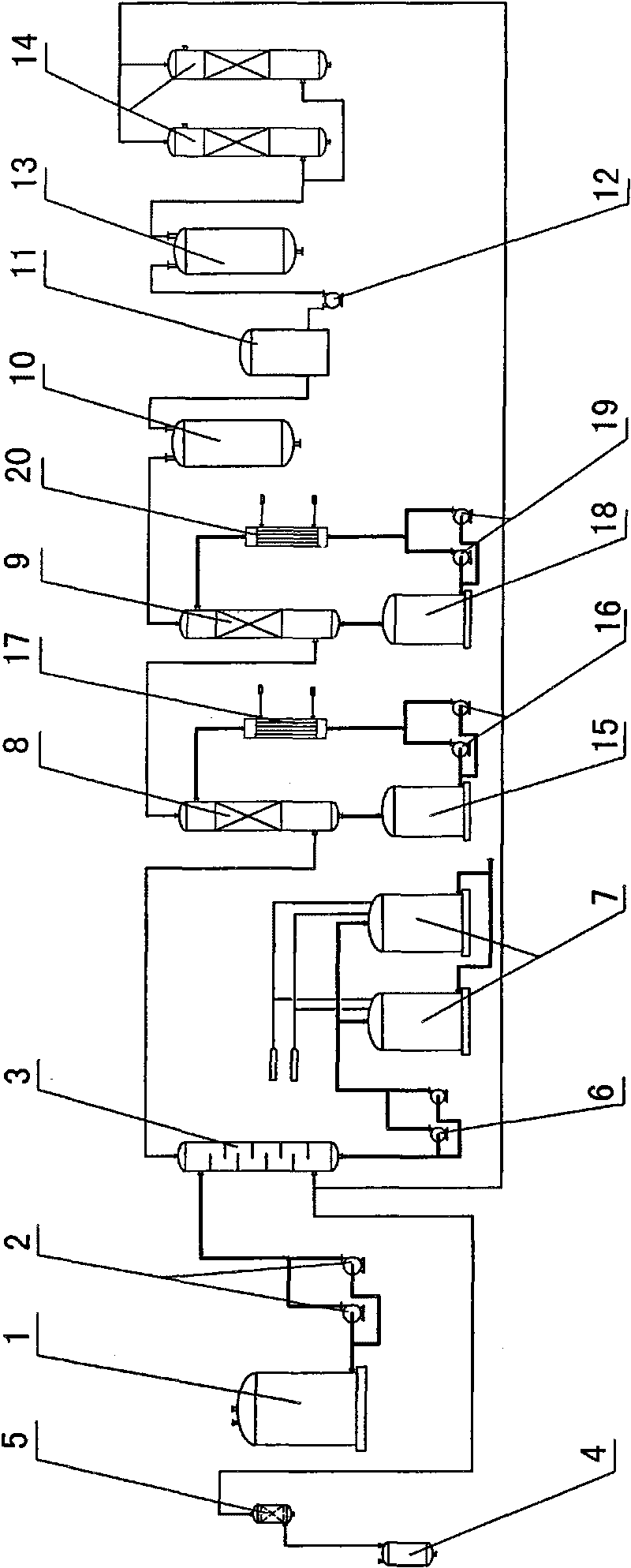

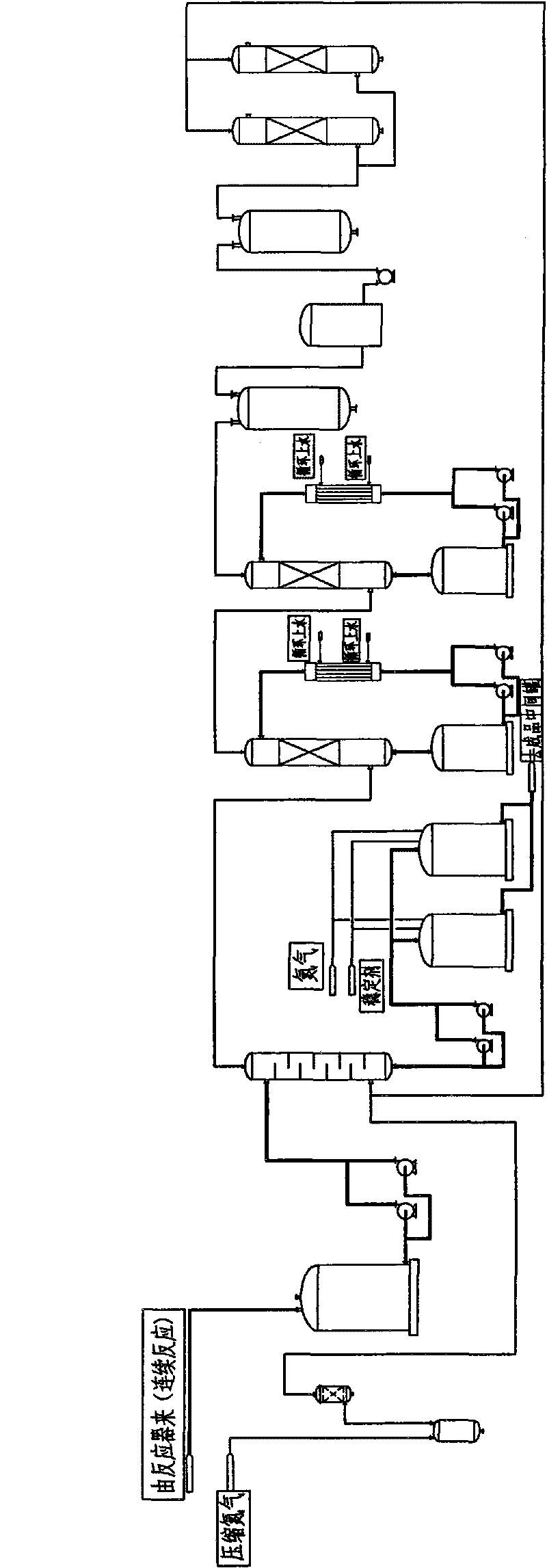

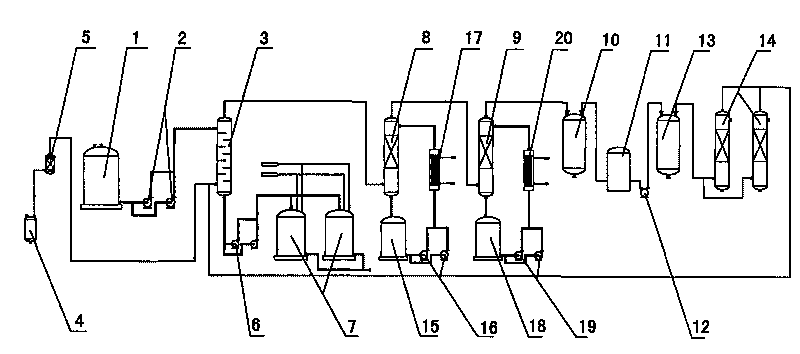

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

[0021] A chlorinated paraffin continuous stripping device, comprising a chlorinated paraffin buffer tank 1, a chlorinated paraffin intermediate pump 2, a chlorinated paraffin stripper 3, a nitrogen buffer tank 4, a nitrogen filter 5, and a chlorinated paraffin stripping pump 6 , chlorinated paraffin intermediate tank 7, acid packing tower 8, alkali packing tower 9, alkali mist trap 10, nitrogen gas cabinet 11, nitrogen compressor 12, water mist trap 13, nitrogen drying tower 14, such as figure 1 As shown, wherein, the chlorinated paraffin buffer tank 1 is communicated with the upper end of the chlorinated paraffin stripper 3 through the chlorinated paraffin intermediate pump 2, and the bottom end of the chlorinated paraffin stripper 3 is connected with the chlorine paraffin stripper 6 through the chlorinated paraffin stripper pump 6. The paraffin intermediate tank 7 is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com