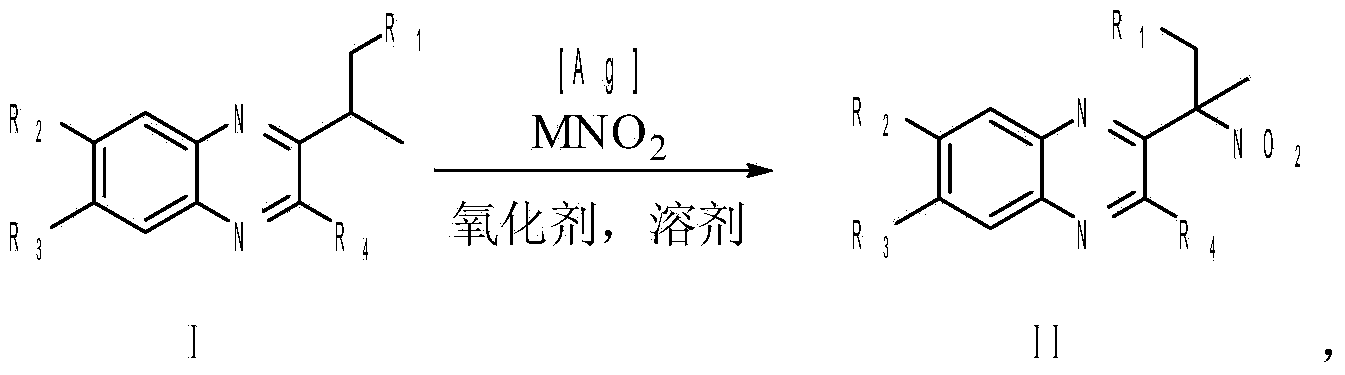

Nitration method of quinoxaline substituted alkane

A technology of quinoxaline and alkanes, which is applied in the field of nitration of quinoxaline-substituted alkanes, can solve problems such as limitations, high energy consumption, and difficulty in obtaining high-purity nitroalkanes, and achieves simple operation, high product purity, The effect of strong substrate universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

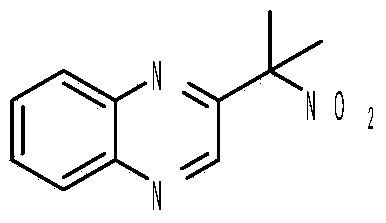

Embodiment 1

[0026]

[0027] Add 0.3mmol of 2-isopropylquinoxaline, 0.45mmol of silver nitrite (silver nitrite serves as both a catalyst and a nitro source), and 0.45mmol of potassium persulfate into a 10mL pressure-resistant reactor, and then add 3mL of 1,2- Dichloroethane was used as the reaction solvent. Then magnetic stirring was performed at 3 bar and 110° C. for 48 h. Then, two spoonfuls of column chromatography silica gel (100-200 mesh) were added to the reaction solution, and the reaction solvent was removed by distillation under reduced pressure, and then the pure product was obtained by column chromatography (based on petroleum ether / ethyl acetate=6: 1 as eluent). The material (2-quinoxalinyl 2-nitropropane) was obtained as a brown oily liquid in 82% yield.

[0028] Characterization data: 1 H NMR (CDCl 3 , 500MHz): δ8.97(s, 1H), 8.16-8.10(m, 2H), 7.84-7.82(m, 2H), 2.19(s, 6H); 13 C NMR (CDCl 3 , 125MHz): δ152.7, 142.3, 142.0, 141.0, 130.8, 130.7, 129.7, 129.2, 90.7, 26.4...

Embodiment 2

[0030]

[0031] Add 0.3mmol of 2-isopropylquinoxaline, 0.06mmol of silver nitrate, 0.45mmol of silver nitrite, and 0.45mmol of potassium persulfate into a 10mL pressure-resistant reactor, and then add 1mL of 1,2-dichloroethane as a reaction solvent. Then magnetic stirring was carried out at 5 bar and 110° C. for 48 h. Then, two spoonfuls of column chromatography silica gel (100-200 mesh) were added to the reaction solution, and the reaction solvent was removed by distillation under reduced pressure, and then the pure product was obtained by column chromatography (based on petroleum ether / ethyl acetate=6: 1 as eluent). The material (2-quinoxalinyl 2-nitropropane) was obtained as a brown oily liquid in 80% yield.

Embodiment 3

[0033]

[0034] Add 0.3mmol of 2-isopropylquinoxaline, 0.06mmol of silver sulfate, 0.45mmol of silver nitrite, and 0.45mmol of potassium persulfate into a 10mL pressure-resistant reactor, and then add 10mL of 1,2-dichloroethane as a reaction solvent. Then magnetic stirring was performed at 8 bar and 100° C. for 72 h. Then, two spoonfuls of column chromatography silica gel (100-200 mesh) were added to the reaction solution, and the reaction solvent was removed by distillation under reduced pressure, and then the pure product was obtained by column chromatography (based on petroleum ether / ethyl acetate=6: 1 as eluent). The material (2-quinoxalinyl 2-nitropropane) was obtained as a brown oily liquid in 56% yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com