Preparation method of high-strength anti-contact-damage porous SiC

A high-strength, high-temperature treatment technology, applied in the field of high-temperature-resistant porous ceramics, can solve the problems that the shape of the wood template cannot be completely maintained, the bionic porous SiC is brittle, and the consumption of the porous oak template can achieve excellent contact damage resistance and high compression. Effect of strength, high compressive strength and resistance to contact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Bamboo with a size of 30mmx20mmx15mm was heated to 900°C at 2°C / min, and carbonized under the protection of argon for 2 hours to obtain a porous carbon template. Use liquid polycarbosilane with a viscosity of 7.8 poise to impregnate under vacuum at room temperature (20°C-28°C) for 3 days, increase the weight by 80% after impregnation, and then cure at 200°C for 2 hours. The impregnated and cured sample was heated to 1100°C at a rate of 10°C / min, and cracked for 5 hours under the protection of argon to obtain biomimetic porous SiC ceramics.

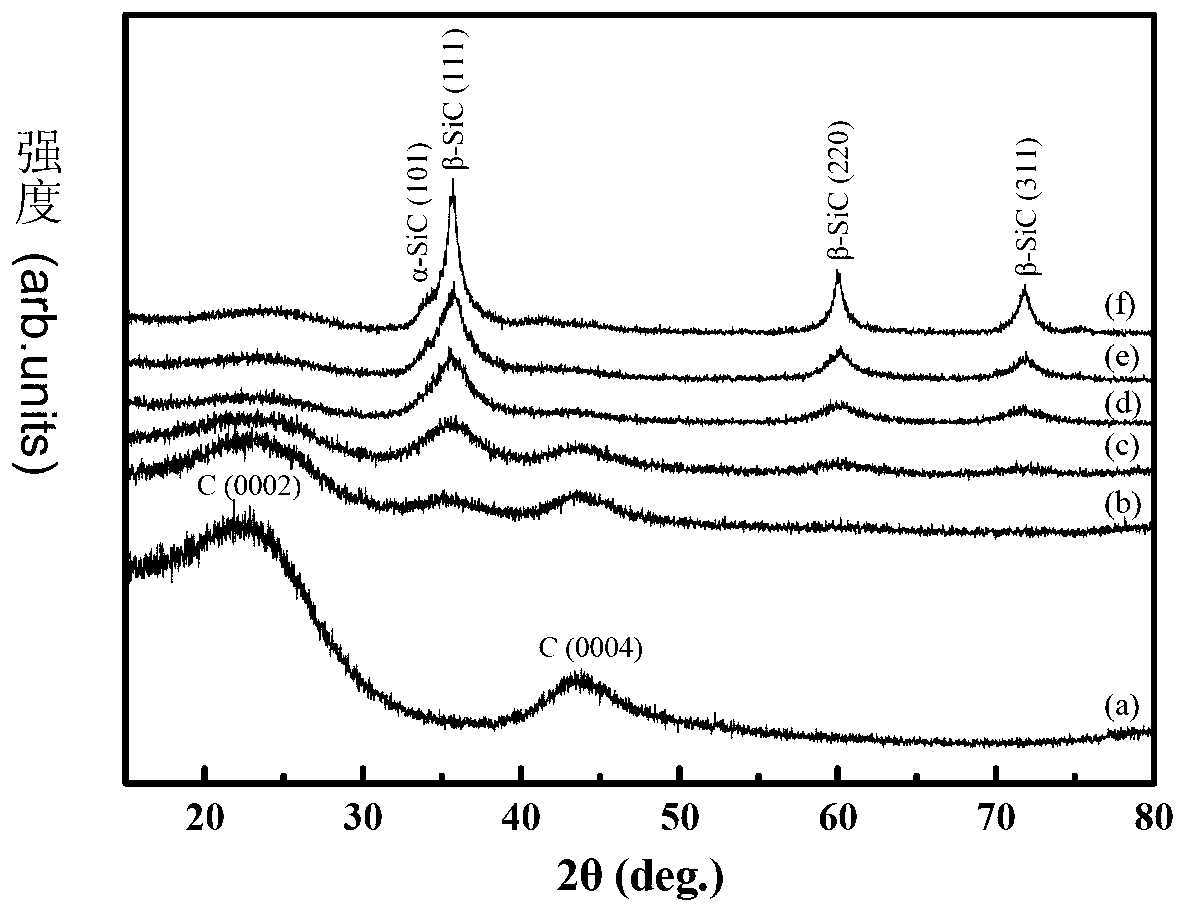

[0033] The porosity of the porous SiC ceramic is 88%. X-ray diffraction analysis, the main components are uncrystallized SiC and carbonized bamboo templates, such as figure 1 (b) shows the X-ray diffraction pattern of the porous SiC material prepared in this example.

Embodiment 2

[0035] Heat pine wood with a size of 30mmx20mmx15mm at 2.5°C / min to 1000°C, and carbonize it under the protection of argon for 5 hours to obtain a porous carbon template. After dipping for 5 days, the weight increased by 83% after dipping, and then cured at 240°C for 2 hours. The impregnated and cured sample was heated to 1200°C at a rate of 10°C / min, and cracked for 5 hours under the protection of helium to obtain biomimetic porous SiC ceramics.

[0036] The porosity of the porous SiC ceramic is 76%. X-ray diffraction analysis, the main components are nanoscale SiC and carbonized pine templates, such as figure 1 (c) shows the X-ray diffraction pattern of the porous SiC material prepared in this example. The compressive strength test shows that the average compressive strength of the biomimetic porous SiC ceramics prepared under this condition is 36.5MPa.

Embodiment 3

[0038] Heat pine wood with a size of 40mmx20mmx25mm at 2°C / min to 1000°C, and carbonize it under the protection of argon for 5 hours to obtain a porous carbon template. After dipping for 6 days, the weight increased by 85% after dipping, and then cured at 240°C for 2 hours. The impregnated and cured sample was heated to 1300°C at a rate of 15°C / min, and cracked for 6 hours under the protection of argon to obtain biomimetic porous SiC ceramics.

[0039] The porosity of the porous SiC ceramic is 77%. X-ray diffraction analysis, the main components are nanoscale SiC and carbonized pine templates, such as figure 1 (d) shows the X-ray diffraction pattern of the porous SiC material prepared in this example. The compressive strength test shows that the average compressive strength of the biomimetic porous SiC ceramics prepared under this condition is 35MPa.

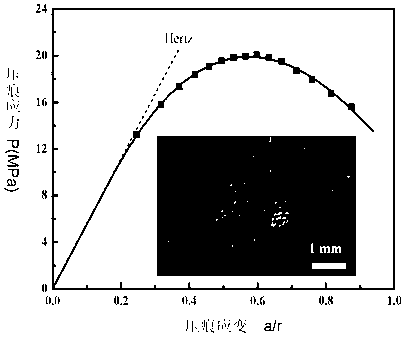

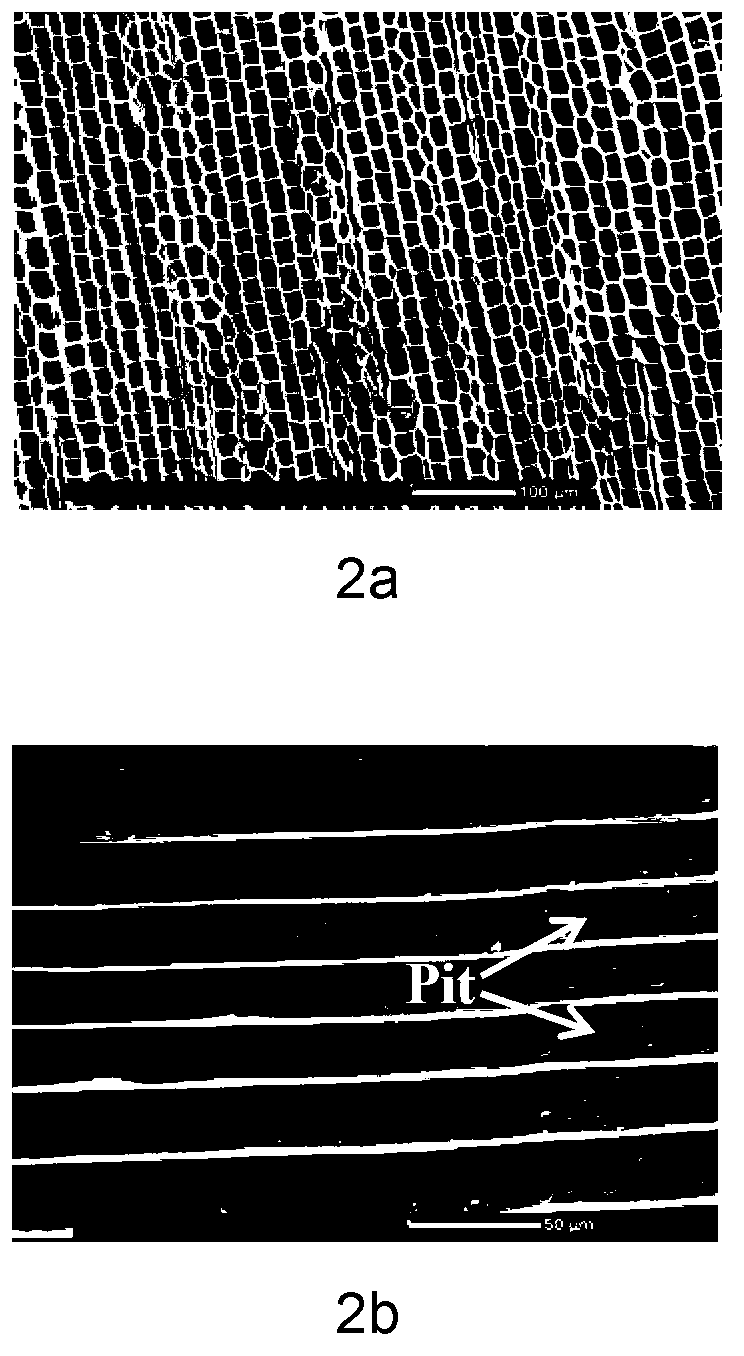

[0040] Scanning electron microscope pictures and energy spectra such as figure 2 As shown, the pore size is 15-20 μm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com