Method for preparing biologic oil from blue algae in catalytic cracking mode in vacuum

A catalytic cracking and bio-oil technology, which is applied in the direction of fat production, fat oil/fat production, etc., can solve the problems of low bio-oil yield, low oil quality, and high production cost, and avoid rare precious metals and toxic metals Use, high oil yield, and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

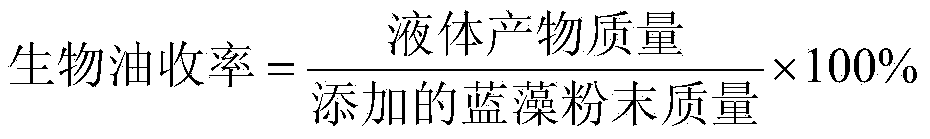

[0029] Calcinate Mg-Al hydrotalcite at 300°C for 1 hour, mix 0.5g of the product with 10g of cyanobacteria powder and put it into a tube furnace with a vacuum of 100kPa, stay at 100°C for 60min, and then heat it at a rate of 10°C / min Raise the temperature to 400°C, crack for 0.5h, and condense the cracked gas through -20°C glass cold hydrazine to collect bio-oil. 6.23g of bio-oil, 2.42g of residual carbon and 1.35g of cracked gas were obtained. The bio-oil yield was 62.3%.

Embodiment 2

[0031] Calcinate Ca-Mg-Al hydrotalcite at 450°C for 3 hours, take 0.5g of the product and 10g of cyanobacteria powder and mix it evenly, then put it into a tube furnace with a vacuum of 50kPa, stay at 100°C for 20min, and then use 10°C / min The heating rate raised the temperature to 400°C, cracked for 1.0h, and the cracked gas was condensed through -20°C glass cold hydrazine to collect bio-oil. 6.37g of bio-oil, 2.34g of residual carbon and 1.29g of cracked gas were obtained. The bio-oil yield was 63.7%.

Embodiment 3

[0033] Calcinate Mg-Al hydrotalcite at 600°C for 5 hours, mix 0.5g product with 10g cyanobacteria powder and put it into a tube furnace with a vacuum of 100kPa, stay at 100°C for 20min, and then heat it at a heating rate of 10°C / min Raise the temperature to 400°C, crack for 1.5 hours, and condense the cracked gas through -20°C glass cold hydrazine to collect bio-oil. 6.42g of bio-oil, 2.35g of residual carbon and 1.23g of cracked gas were obtained. The bio-oil yield was 64.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com