Three return stroke half fire coal, fuel oil and gas-fired smokeless boiler

A three-return, boiler technology, applied in the fields of fuel oil, three-return semi-coal-fired, and gas-fired smokeless boilers, can solve the problems of easy scaling, poor heat transfer efficiency, and difficulty in cleaning, saving fuel costs, high assembly accuracy, Easy to assemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

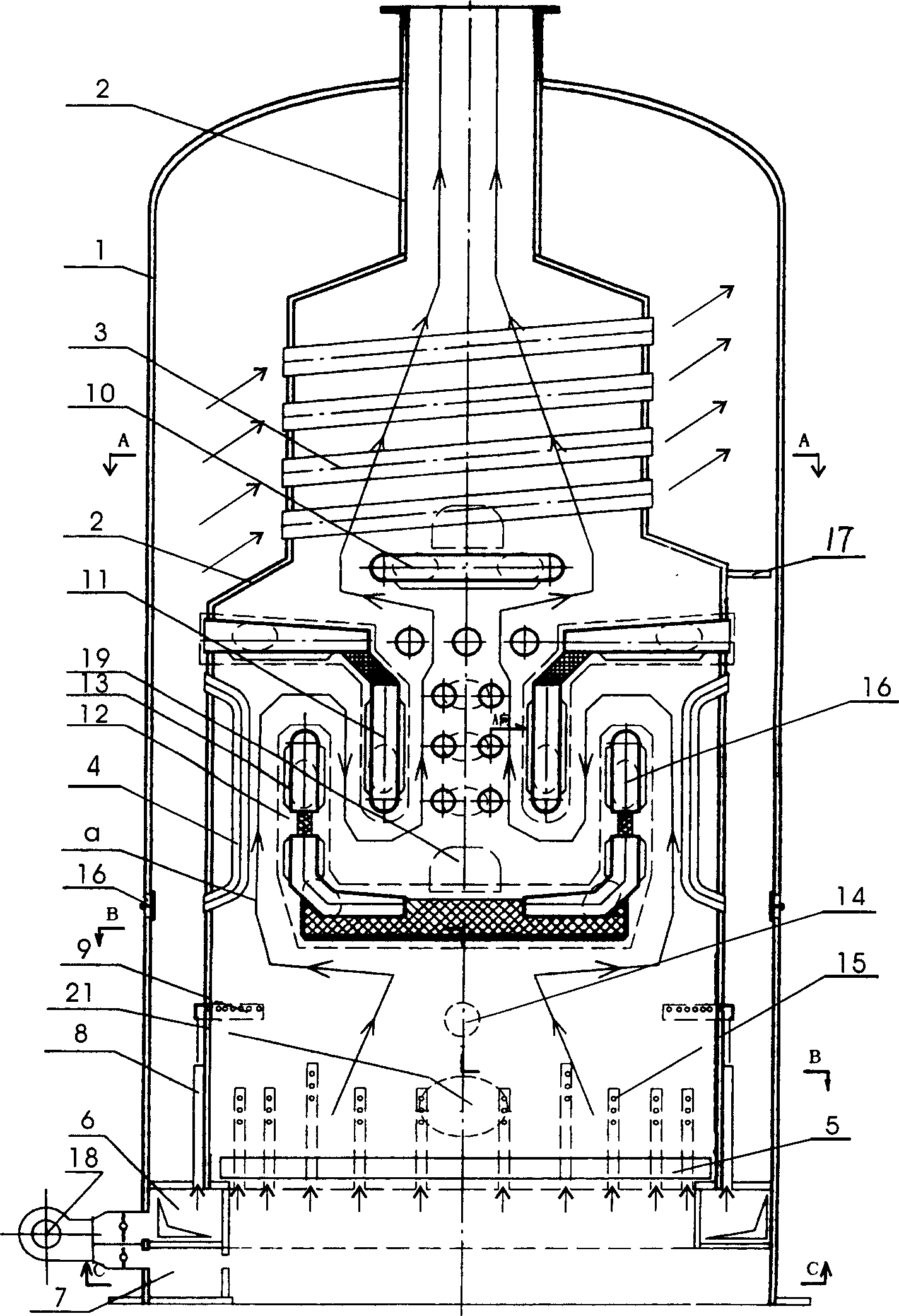

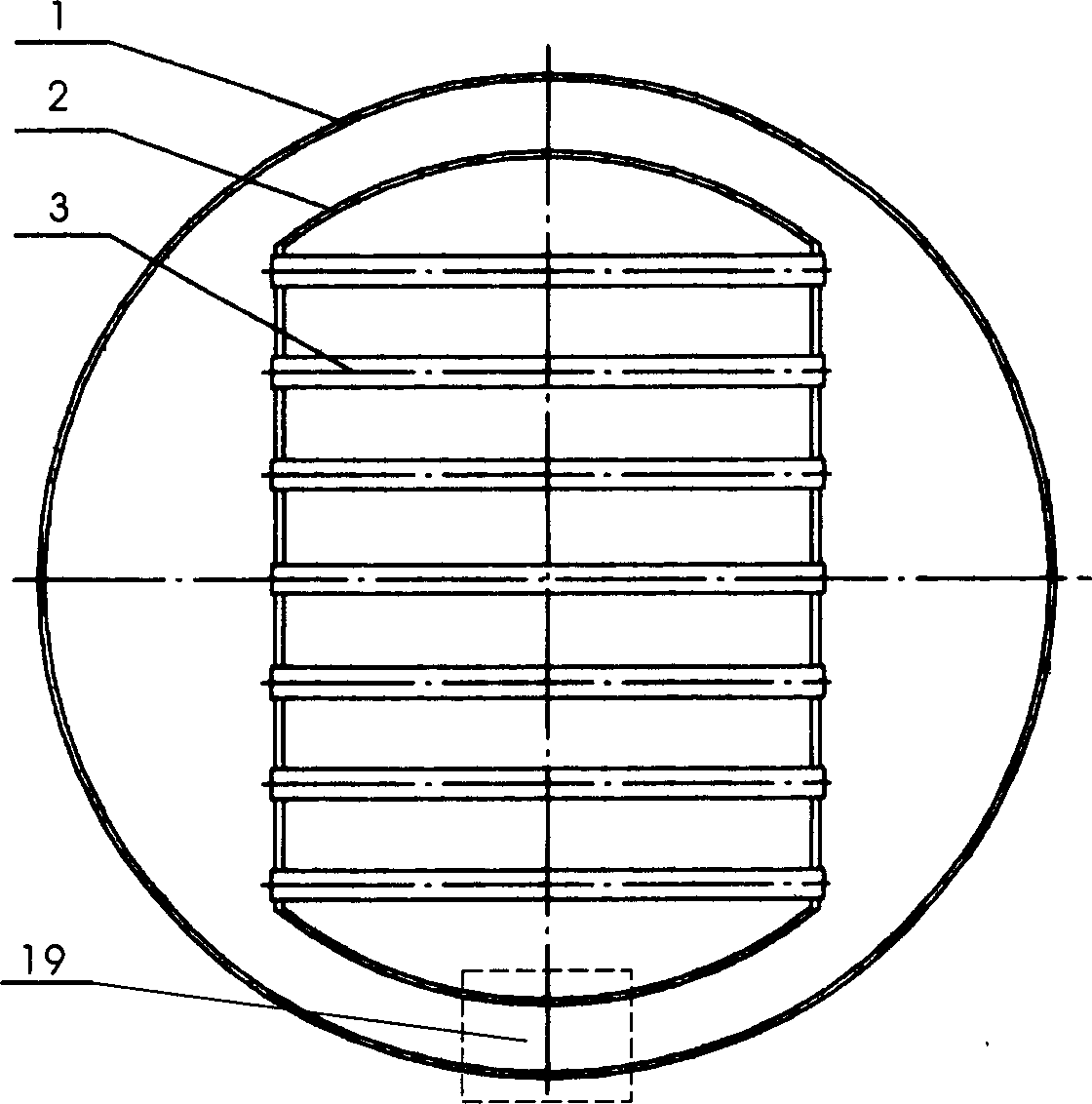

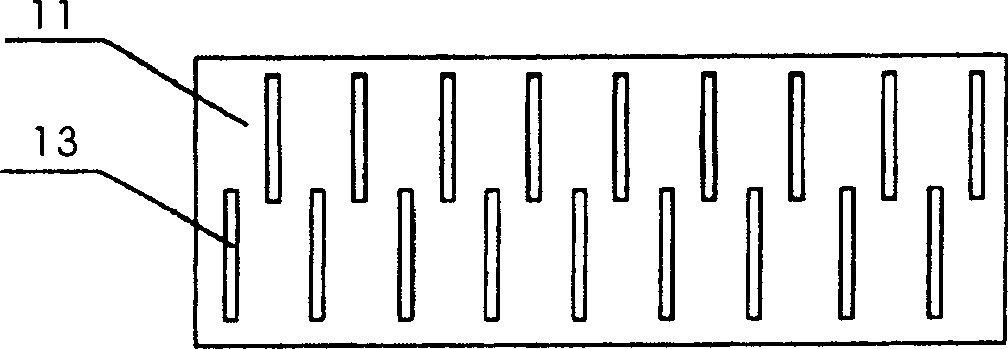

[0034] The three-pass and half-pass coal-fired, fuel-fired and gas-fired smokeless boiler of the present invention includes a boiler body composed of a boiler outer cylinder 1 and an inner tank shell 2. A fire grate 5 is installed at the bottom of the boiler body, and the fire grate 5 connects the boiler body The lower space of the furnace is divided into the upper furnace space area and the lower furnace base area. The annular secondary air bellows 6 and the bow-shaped primary air bellows 7 are installed in the furnace base area from top to bottom. 7 are all connected to the fan 18 outside the boiler; there are 2 to 6 air distribution ports 15 on the vertical surface of the bow-shaped primary air box 7, and the air distribution ports 15 are round holes of φ40~φ150; the annular secondary air box 6 is connected to the A number of vertical secondary air distribution pipes 8 of different heights placed on the outer wall communicate with each other, and two crescent-shaped horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com