Technology and equipment for increasing concentration of soda straw pulp black liquor

A technology of straw pulp black liquor and process, which is applied in the direction of concentrating waste liquid, etc., can solve the problems of incombustibility and low thermal efficiency of straw pulp black liquor, and achieve the effects of reducing volume, improving thermal efficiency and increasing heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

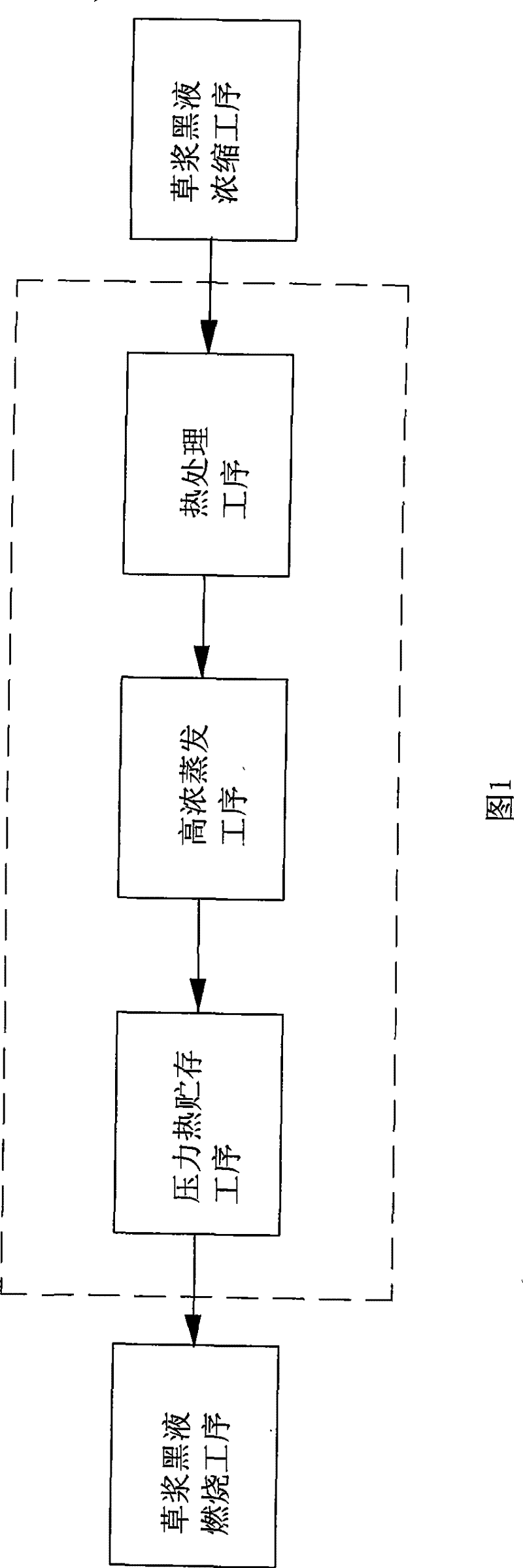

[0023] figure 1It is a block diagram of a process flow for increasing the concentration of straw pulp black liquor provided by the present invention, wherein the process steps in the dotted frame are the content of the present invention. As shown in the figure, it is a process for increasing the concentration of straw pulp black liquor in the alkaline method, which is characterized in that it is arranged between the concentration process of black liquor in straw pulp and the burning process of black liquor in straw pulp in the traditional alkaline method of straw pulp alkali recovery process, specifically The steps are as follows: (1). Heat treatment: The thick straw pulp black liquor provided by the straw pulp black liquor concentration process is firstly pre-pressurized, pre-heated to a pressure of 0.5-0.8Mpa and a temperature of 140-160°C, and then further pressurized and heated to : The final pressure is 1.0 ~ 1.2Mpa, the final temperature is 175 ℃ ~ 180 ℃, and put it into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com