Briquette furnace

A technology of briquette furnace and furnace shell, which is applied in the field of briquette furnace, can solve the problems of environmental pollution, large heat energy loss, many and laborious action processes, etc., and achieve the effect of less fly ash, less heat loss, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

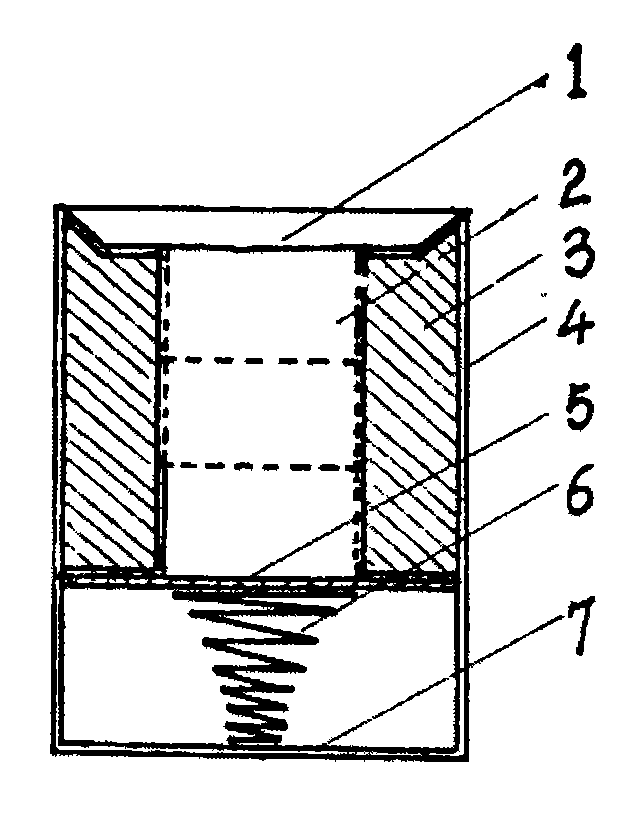

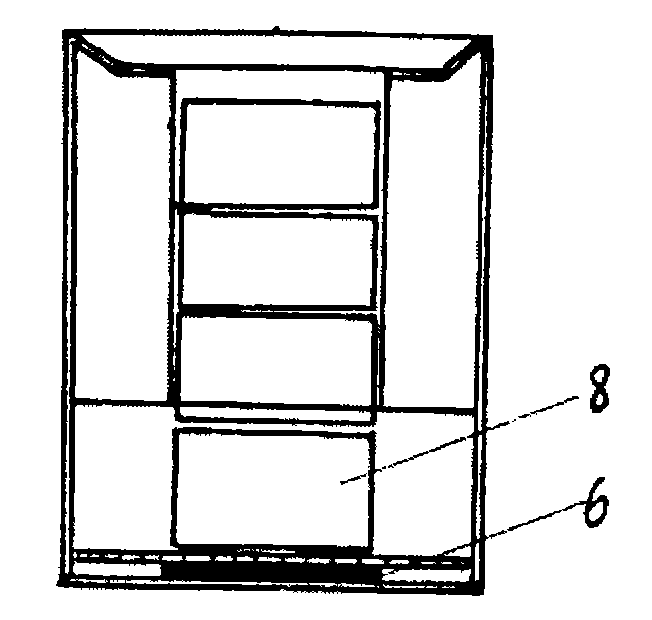

[0009] As shown in the figure, the furnace grate 5 is an independent circular grate, its periphery is close to the inner wall of the furnace shell 4, the upper part is close to the lower side of the furnace wall 3, and a compression spring is preferably an inverted tower below it. Shaped spring 6 supports, and tower shape spring elastic force is suitable, promptly when putting full briquettes in the hearth on the fire grate, the supporting elastic force of spring should be as follows: figure 1 The state shown is not excessively pressed down by the gravity of the briquettes; and when the exhausted briquettes are removed and a new briquette is added from the furnace mouth 1, the spring is properly compressed by the increased gravity, and the pot on the furnace mouth, etc. Gravity, the grate and the tower spring are compressed downwards as figure 2 In the state of middle 6, at this moment, then available coal clips can be used to clamp or hook out the exhausted briquettes 8 (com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com