Sludge biomass forming fuel

A briquette fuel and biomass technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of heavy economic burden, high operating cost, complicated process, etc., and achieve the effects of reducing investment, increasing production, and reducing black smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

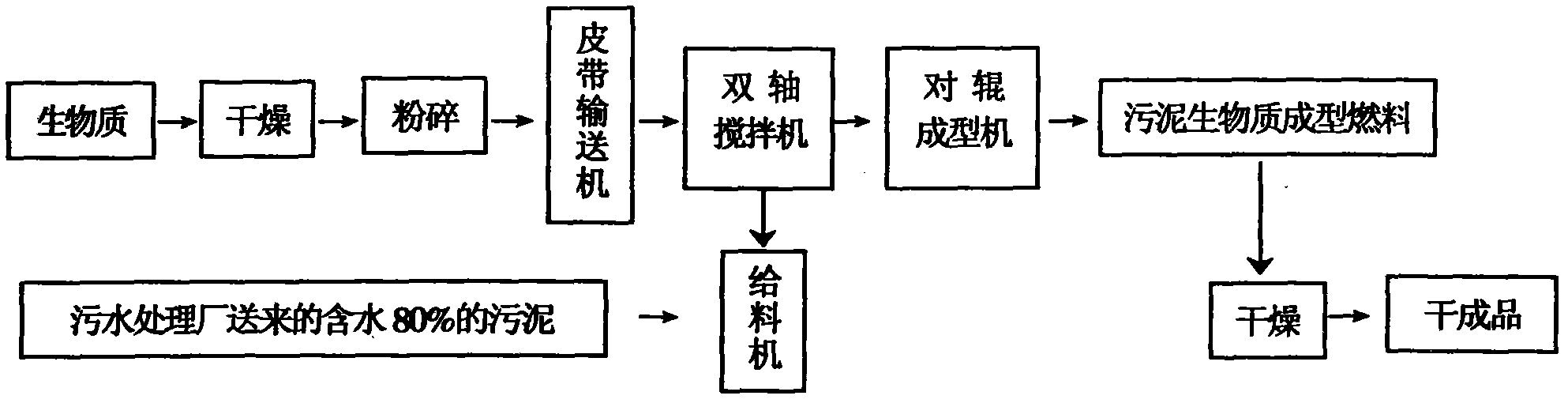

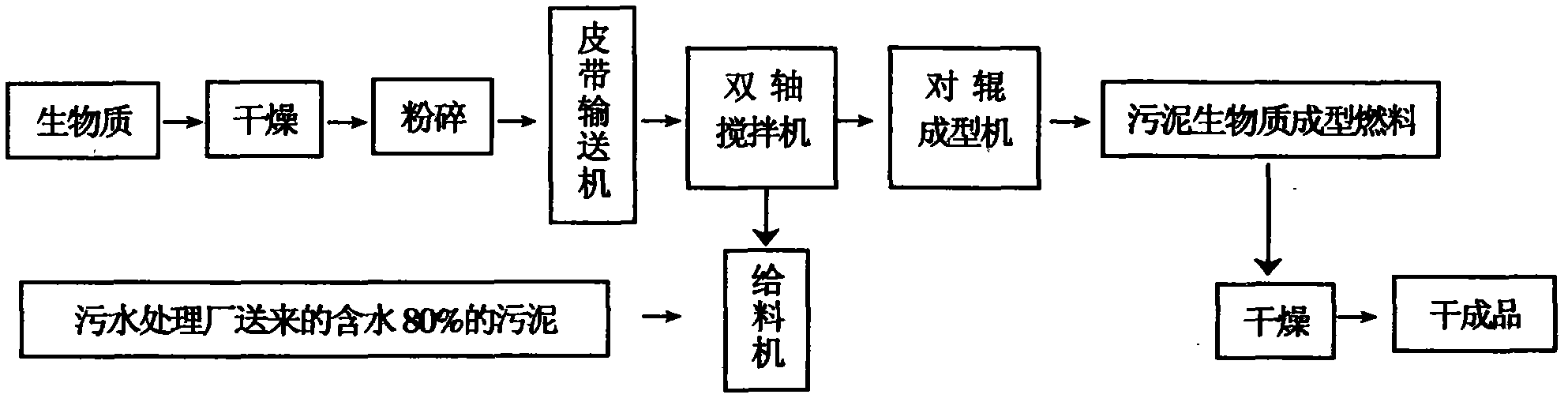

[0012] On the basis of the existing biomass briquette fuel production process, the original ring die roll forming machine is changed to a double-roll forming machine or stamping forming machine that costs less than 1 / 10 of the same output, and the original screw feeder is changed to It is a double-shaft mixer and a simple sludge feeder is added to produce sludge biomass briquette fuel. The ratio of biomass powder to sludge with a water content of 80% is mainly controlled by the water content of the molding. The process is simple, the cost is low, the output is high, and the quality is good. If it is shaped nearby, it can be burned directly in the furnace; if it needs to be stored for a short time, it can be stabilized by adding lime. It is best to dry at 120-160°C to kill all microorganisms before leaving the factory for sale. If other binders are used, the biomass briquette can also be produced with a roll forming machine or a stamping forming machine.

[0013] Because the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com