Solid waste incinerator body

A solid waste and incinerator technology, applied in incinerators, non-flammable liquid/gas transportation, combustion methods, etc., can solve problems such as furnace temperature drop, resource waste, and furnace temperature instability, so as to reduce heat loss, Improved thermal efficiency and remarkable energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail by the following examples.

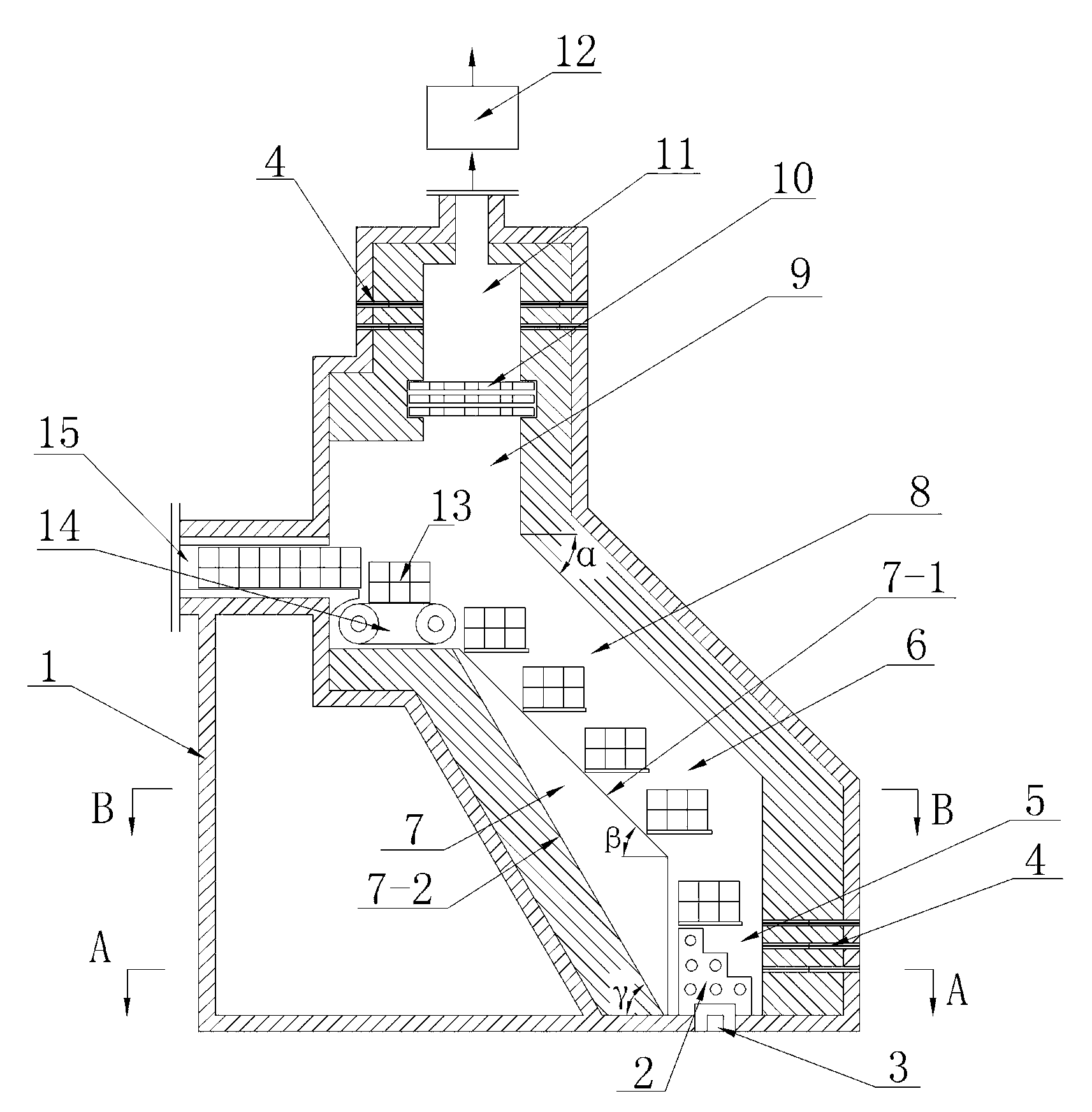

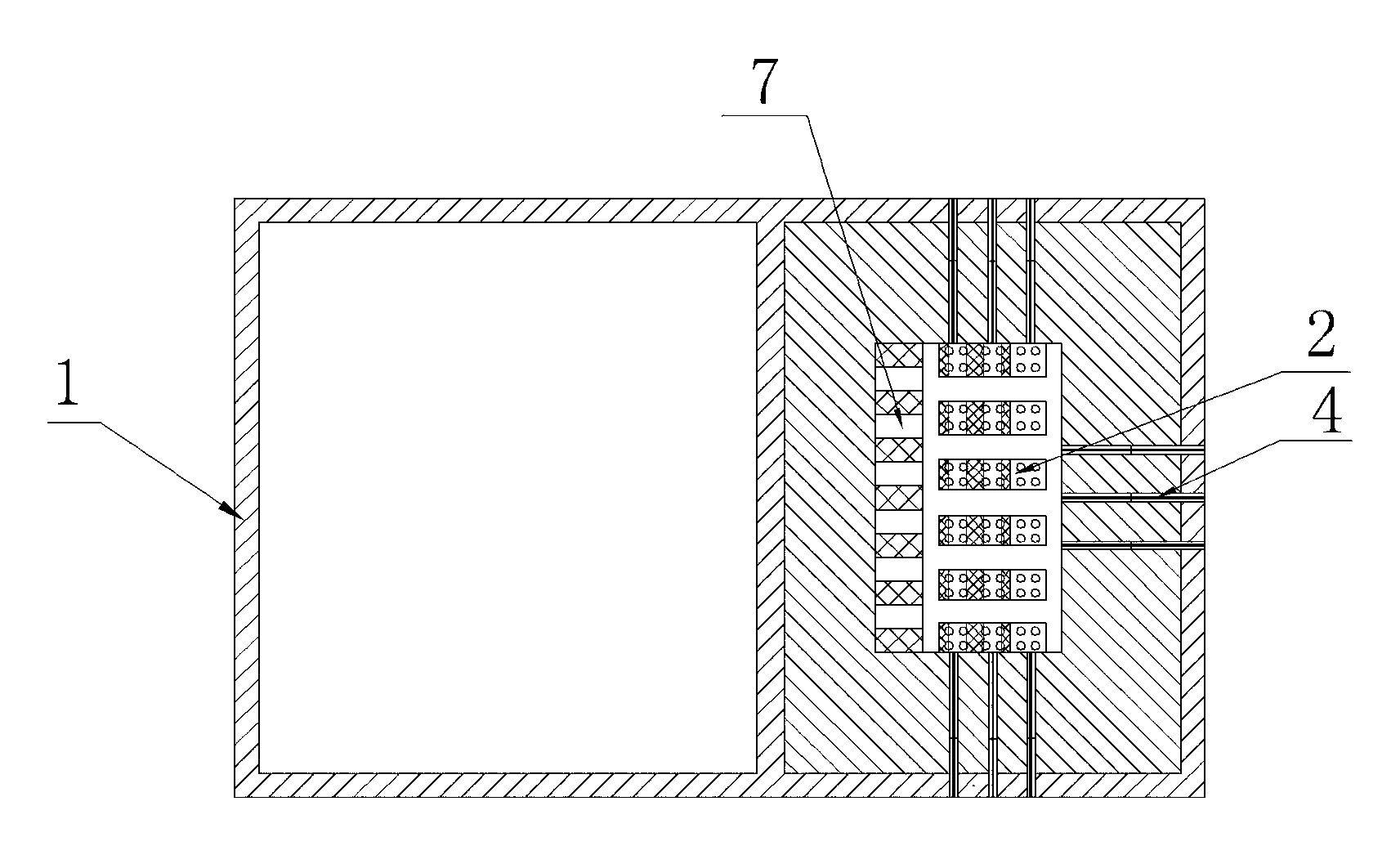

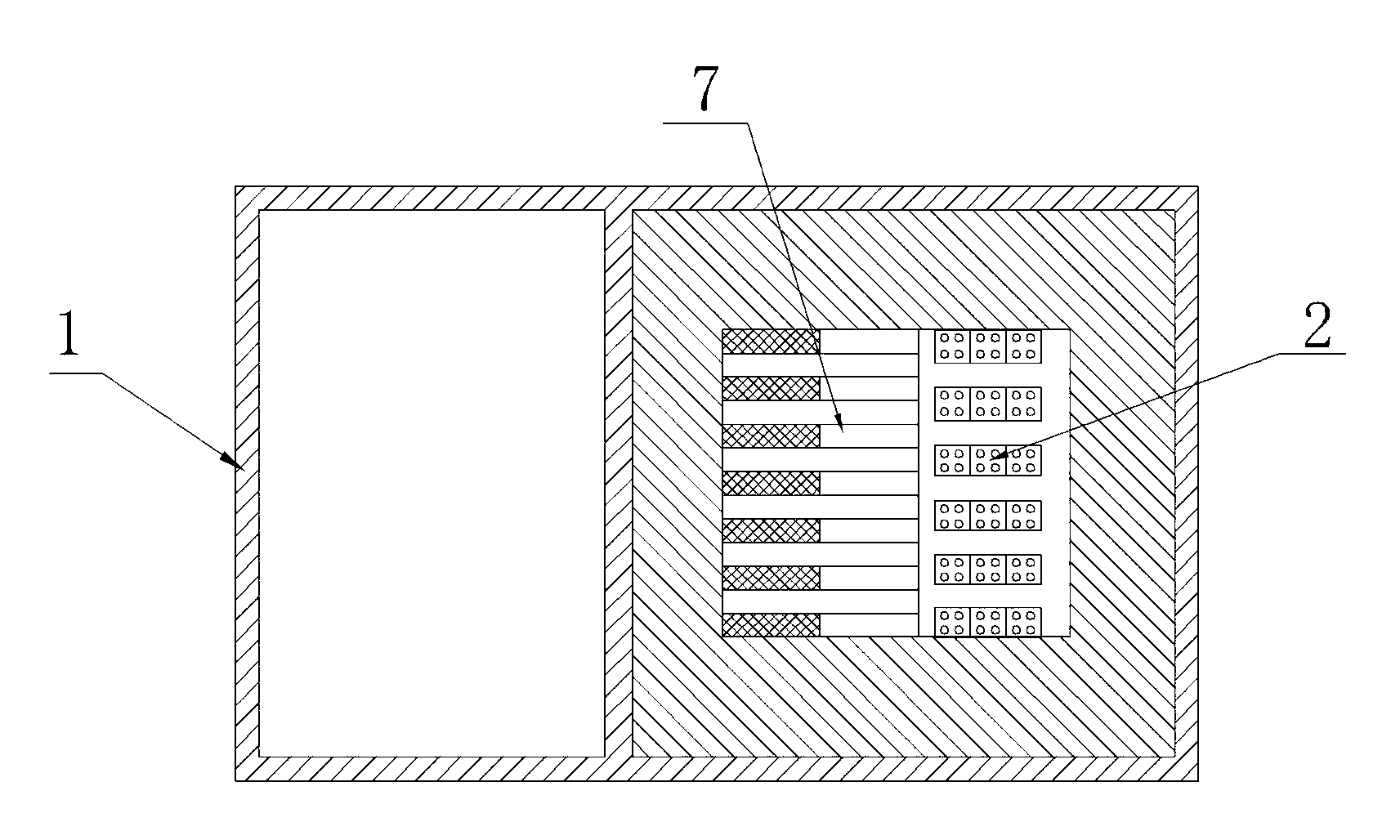

[0022] see figure 1 — image 3As shown, a solid waste incinerator body consists of a vertically structured incinerator body 1 , a vertically structured incinerator hearth 9 , a high temperature resistant belt conveyor 14 , a boiler hearth 11 , and an induced draft fan 12 . The furnace 9 of the incinerator is provided with a drying area 8 , a pyrolysis area 6 and a combustion area 5 sequentially from top to bottom. The bottom of the combustion area 5 is provided with an ash outlet 3 , and the ash outlet 3 is provided with a grid 2 . The cross-section of the incinerator hearth 9 is square, and a group of heated kangs 7 parallel to each other and vertically arranged are arranged inside the drying zone 8, the pyrolysis zone 6, and the combustion zone 5 of the incinerator hearth 9, and the heated kang surface 7-1 The included angle β=40°-50° angle with the horizontal plane, and the included a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com