Sacrificial offering incinerator provided with smoke cleaning system

A flue gas purification system and incinerator technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problem of high air pollutant emissions, low pollution control level, and difficulty in adapting to the industry development situation and atmospheric environment management situation Requirements and other issues to achieve the effect of reducing fly ash, reducing blackness and fuel consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

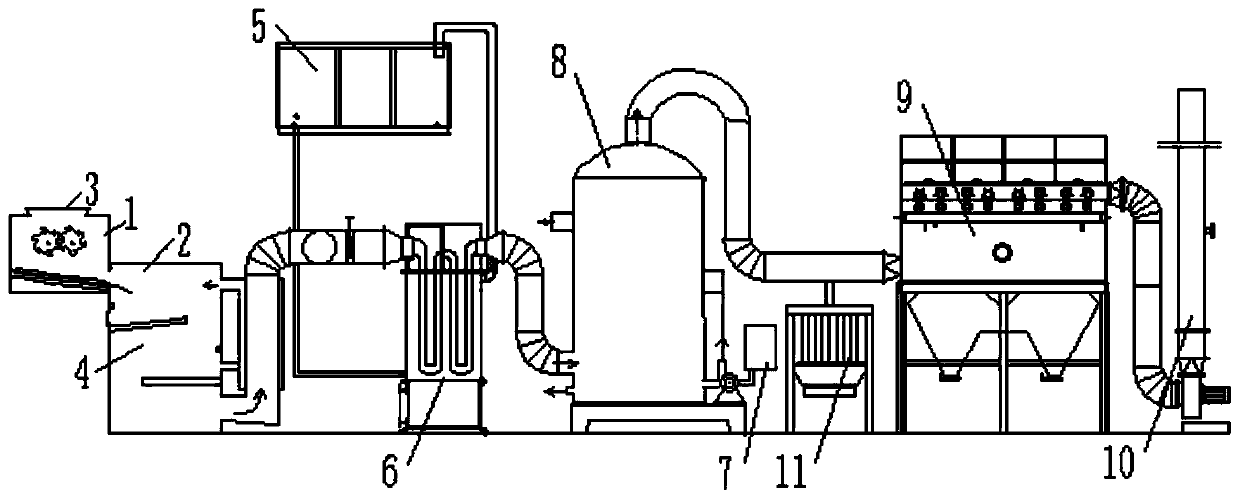

[0022] Such as figure 1 As shown, the present invention includes a crushing bin 1, an incinerator, a quench tower 6, a spray tower 8, an activated carbon injection device 11, a bag filter 9 and a chimney 10 connected sequentially through a flue gas pipeline, and the remains and offerings are pretreated and incinerated. , purification and other steps, the purified flue gas is discharged into the atmosphere through the chimney.

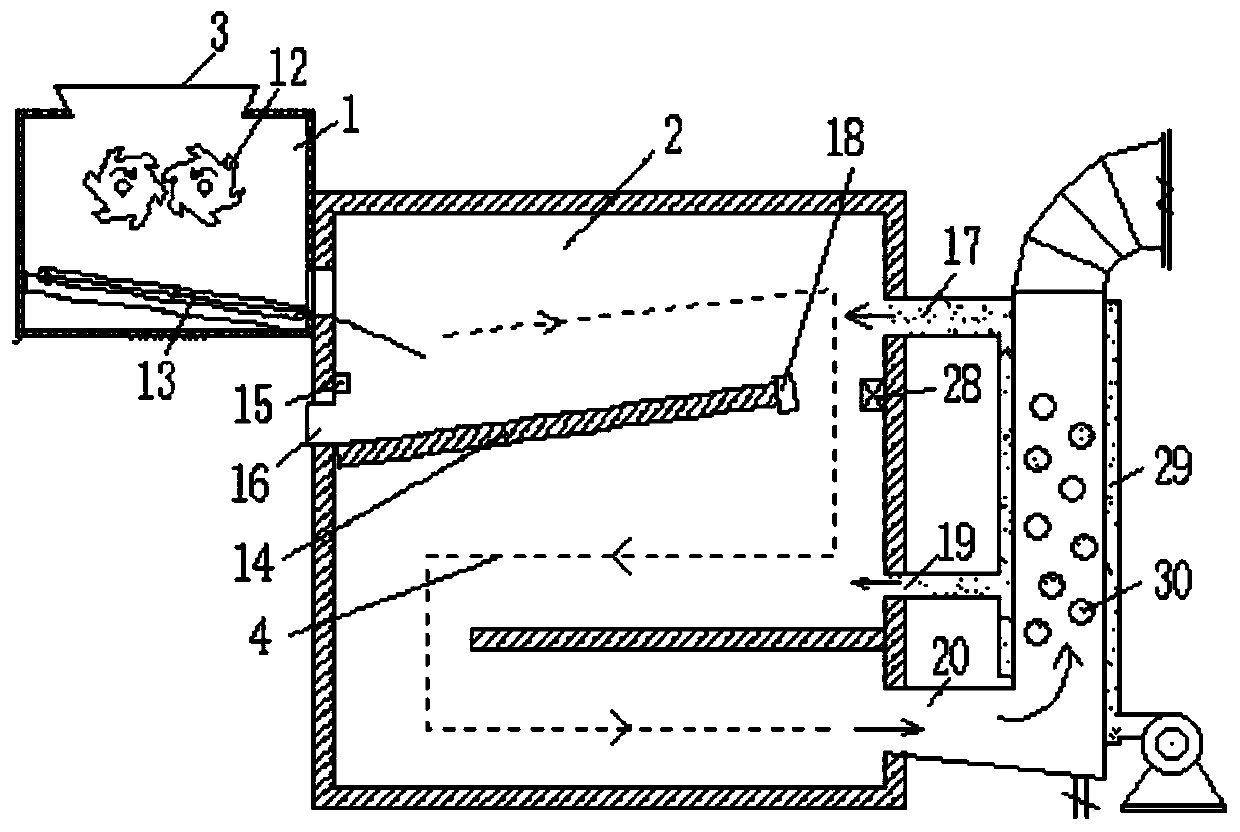

[0023] The crushing bin 1 includes a feeding port 3, a reamer 12 and a conveyer belt 13. The feeding port 3 is on the top of the crushing bin, and an openable door is arranged on the outside thereof. Two rows of reamers 12 are installed below the delivery port, and the reamer circumference is a toothed blade, and the two rows of reamers rotate relatively. There is a discharge port on the side wall at the bottom of the crushing bin, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com