Ionic liquid additive-containing gel battery electrolyte

A technology of ionic liquid and colloidal batteries, which is applied in the direction of lead-acid batteries, etc., can solve the problems of poor starting performance at low temperature, short service life, serious self-discharge, etc., and achieve the effects of reducing short circuit, long service life and prolonging discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

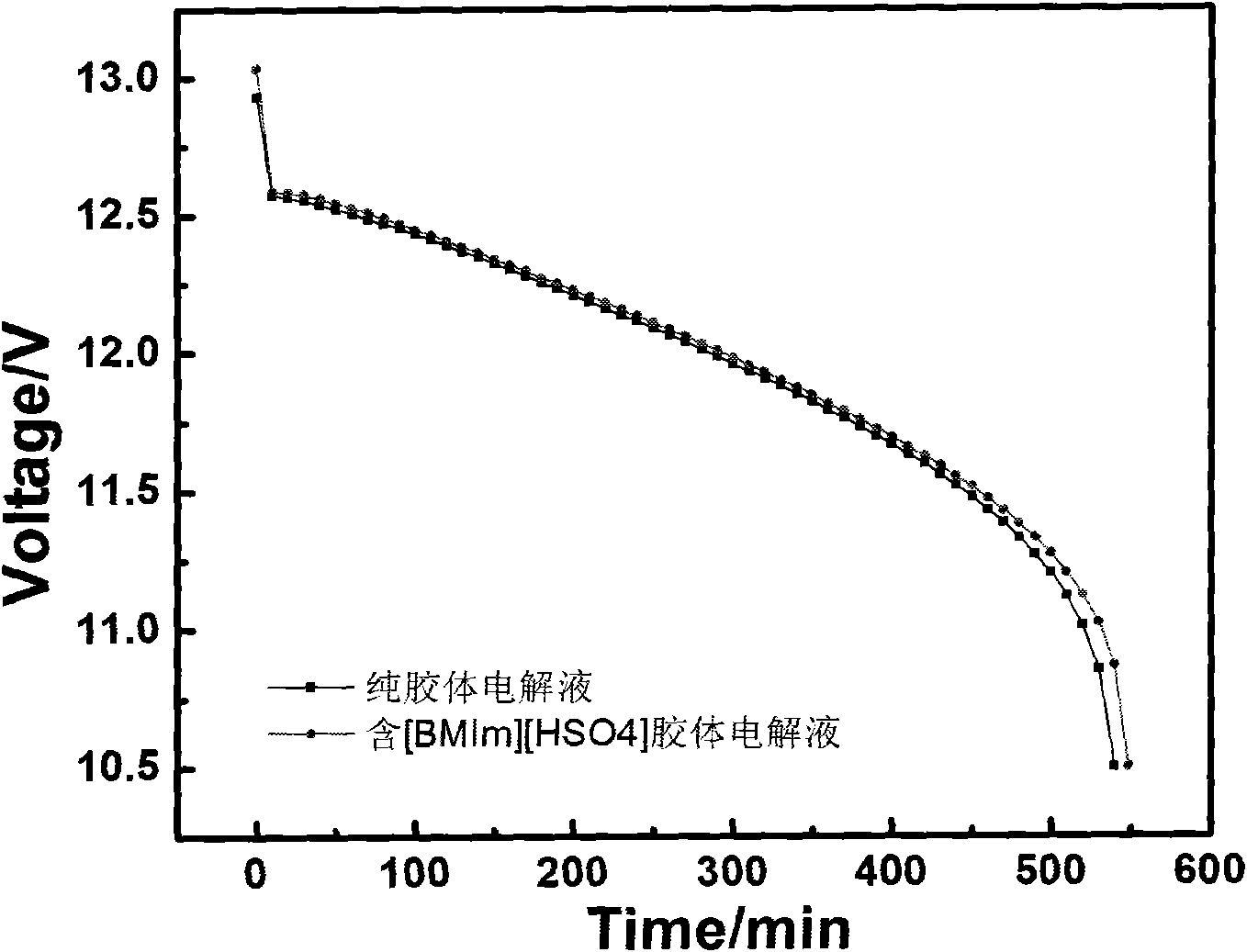

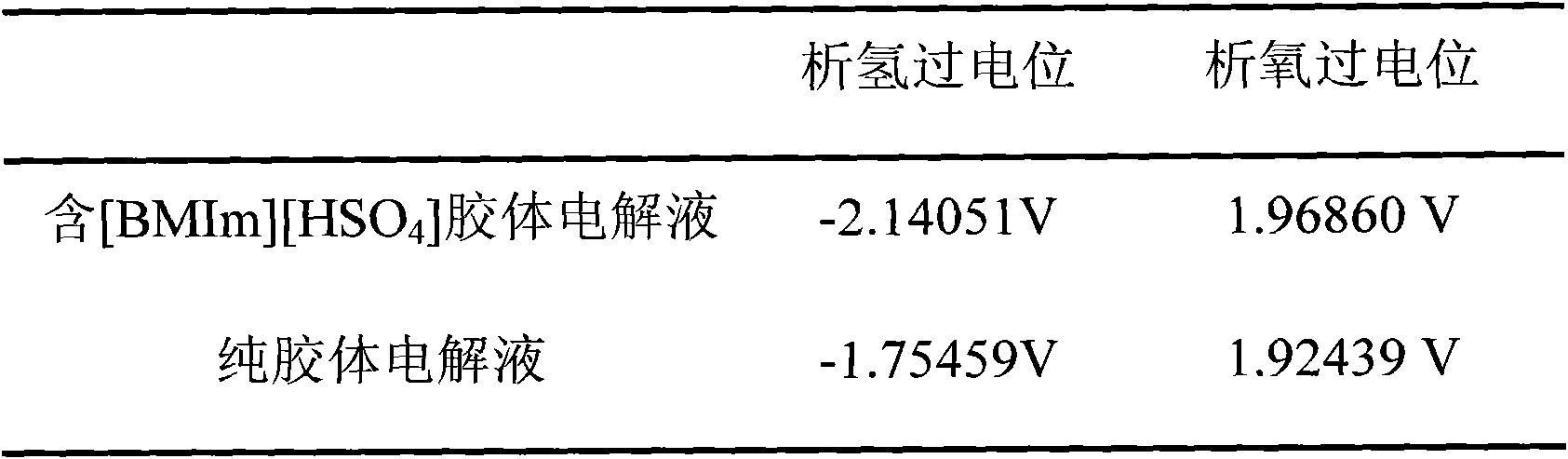

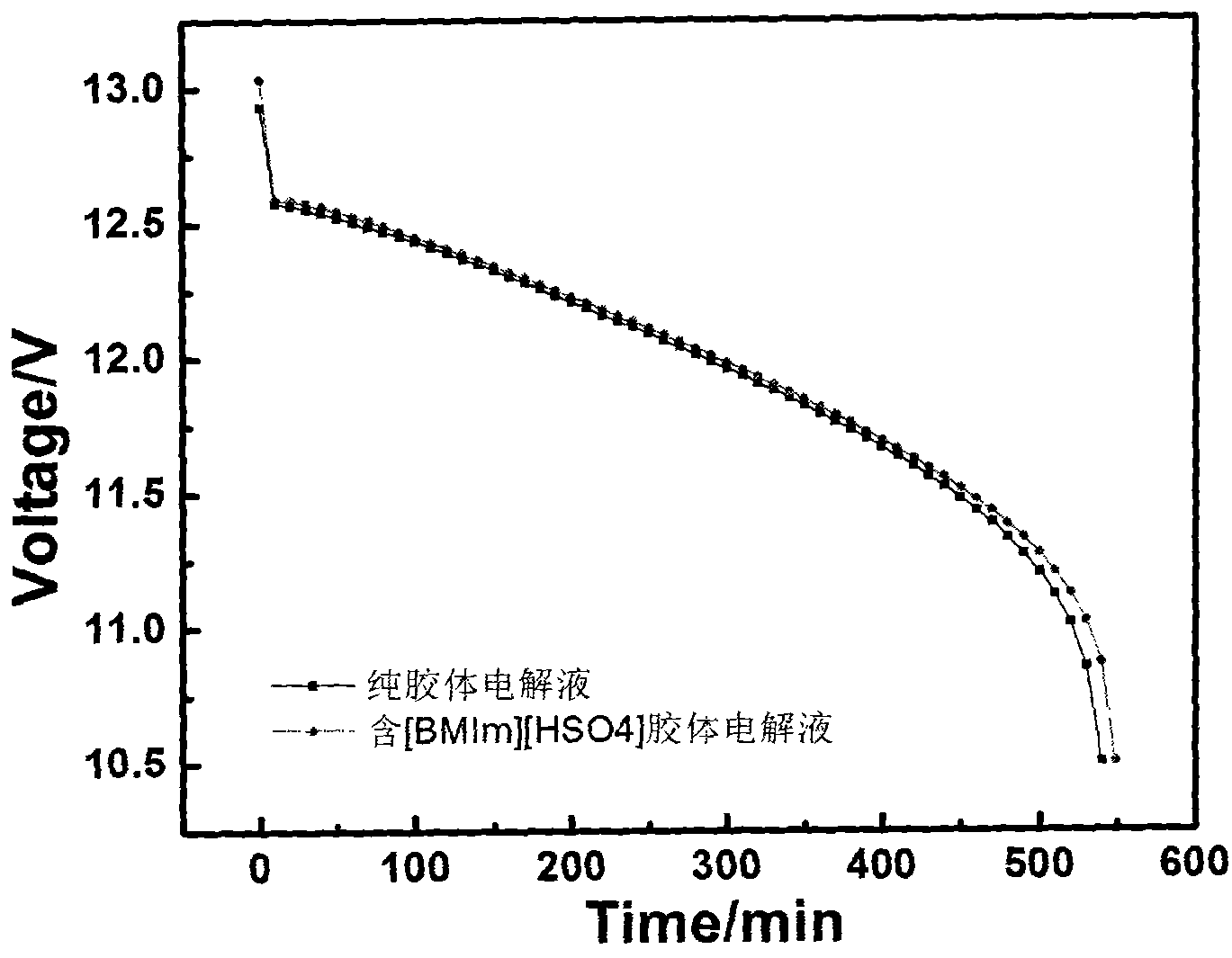

Embodiment 1

[0026] When preparing colloidal electrolyte, get 32% sulfuric acid, 59.97% water and 0.3‰ of 1-ethyl-3-methylimidazolium bisulfate ionic liquid ([BMIm][HSO 4 ]) The additive is placed in the polytetrafluoroethylene dispersion barrel and fixed on the high-speed disperser. After mixing the two evenly at a low speed, add 8% silica sol as a gelling agent, and disperse at a high speed for a certain period of time to obtain the colloidal sol , Immediately inject it into the battery as a colloidal electrolyte, place it until the glue is solidified, and then perform a charge and discharge test.

Embodiment 2

[0028] When preparing colloidal electrolyte, get 38% sulfuric acid, 55.98% water and 0.2‰ of 1-ethyl-3-methylimidazolium bisulfate ionic liquid ([BMIm][HSO 4 ]) The additive is placed in the polytetrafluoroethylene dispersion barrel and fixed on the high-speed disperser. After mixing the two evenly at a low speed, add 6% silica sol as a gelling agent, and disperse at a high speed for a certain period of time to obtain the colloidal sol , Immediately inject it into the battery as a colloidal electrolyte, place it until the glue is solidified, and then perform a charge and discharge test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com