Method for improving electric capacity of anode of electrochemical capacitor of organic system

An organic system and electrochemical technology, applied in the field of organic system electrochemical supercapacitors, can solve problems such as the inability to apply electrochemical supercapacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In the first step, 1 mg of ferrocene (FC) is first added to the N-methylpyrrolidone solution containing 10 mg of binder polyvinylidene fluoride, and the ferrocene is completely dissolved in an ultrasonic disperser by ultrasonic oscillation. Dissolve in the binder solution, the ultrasonic time is 60min, the ultrasonic power is 100W, and then stand for 5min; the second step, add 80mg of activated carbon powder with high specific surface area and 10mg of conductive carbon black into the binder solution, stir evenly, Then put the slurry into an ultrasonic disperser for 1 hour, so that the components in the slurry are completely dispersed evenly, and the ferrocene is highly dispersed in the activated carbon powder; the third step is to coat the uniformly dispersed slurry on the conductive substrate , such as the surface of aluminum foil, put it in an oven, dry it under vacuum at 110°C for 3 hours, and then cool it down to room temperature naturally.

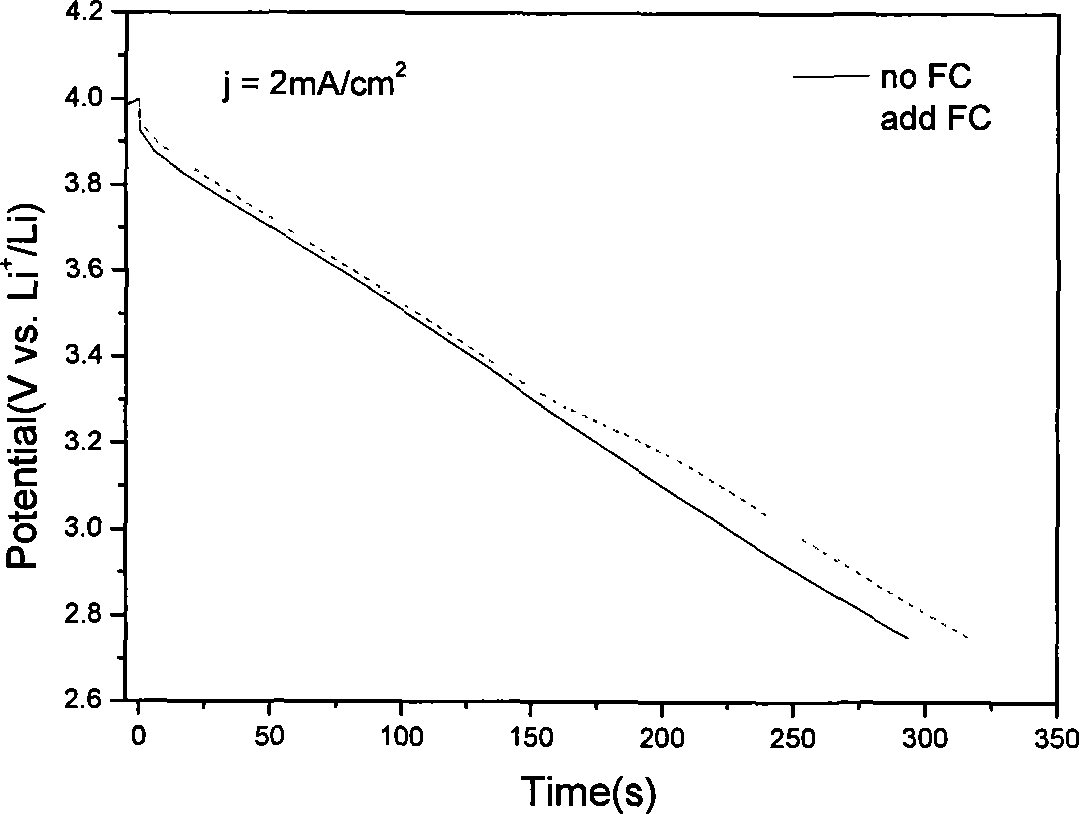

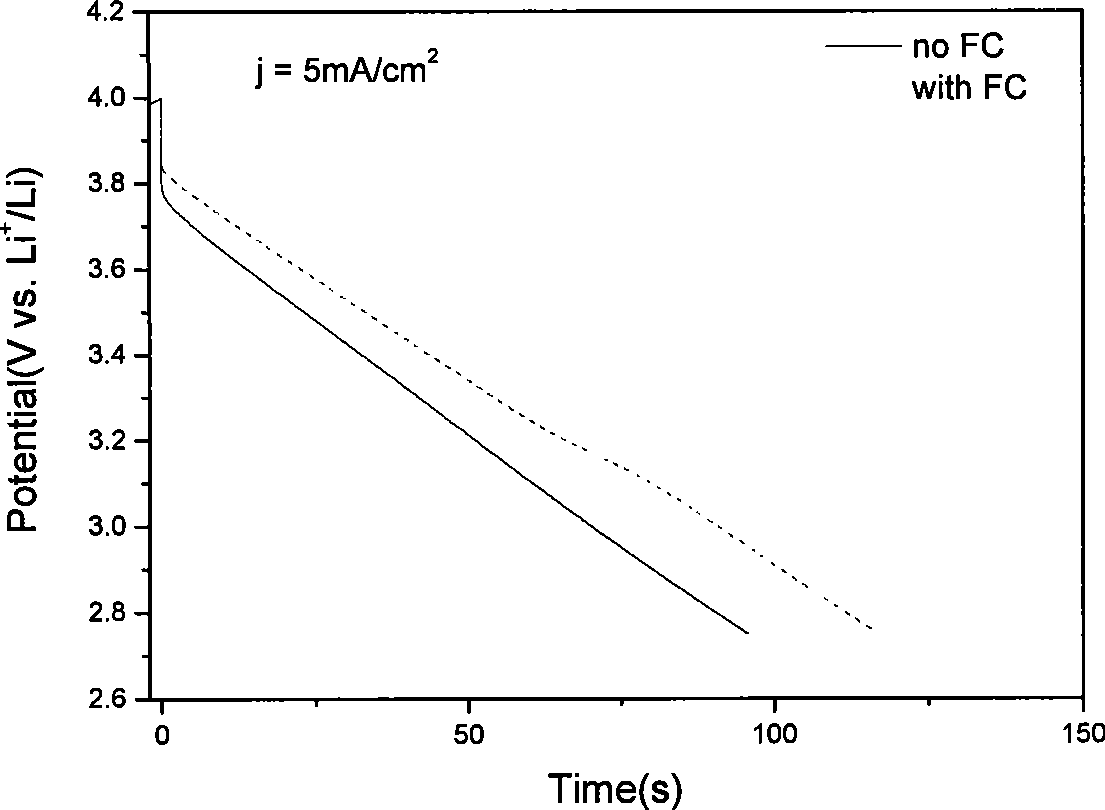

[0023] Take out the dri...

Embodiment 2

[0026] In the first step, 5 mg of ferrocene is first added to the N-methylpyrrolidone solution containing 10 mg of binder polyvinylidene fluoride, and the ferrocene is completely dissolved in the viscous solution by ultrasonic oscillation in an ultrasonic disperser. In the binder solution, the ultrasonic time is 1h, the ultrasonic power is 400W, and then it is left to stand for 10min; the second step is to add 80mg of activated carbon powder with a high specific surface area and 10mg of conductive carbon black to the binder solution, stir evenly, and then put the slurry The material is put into an ultrasonic disperser and ultrasonicated for 2 hours, so that the components in the slurry are completely dispersed evenly, and the ferrocene is highly dispersed in the activated carbon powder; the third step is to coat the uniformly dispersed slurry on a conductive substrate, such as aluminum foil surface, put it in an oven, dry it under vacuum at 110°C for 5 hours, and let it cool do...

Embodiment 3

[0030] In the first step, 10 mg of ferrocene is first added to the N-methylpyrrolidone solution containing 10 mg of binder polyvinylidene fluoride, and the ferrocene is completely dissolved in the viscous solution by ultrasonic oscillation in an ultrasonic disperser. In the binder solution, the ultrasonic time is 3 hours, the ultrasonic power is 600W, and then it is left to stand for 30 minutes; the second step is to add 80 mg of activated carbon powder with a high specific surface area and 10 mg of conductive carbon black into the binder solution, stir evenly, and then put the slurry The material is put into an ultrasonic disperser and ultrasonicated for 5 hours, so that the components in the slurry are completely dispersed evenly, and the ferrocene is highly dispersed in the activated carbon powder; the third step is to coat the uniformly dispersed slurry on a conductive substrate, such as aluminum foil surface, put it in an oven, dry it under vacuum at 110°C for 12 hours, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com