Biomass briquette fuel and preparation method thereof

A briquette fuel and biomass technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of high transportation costs, restrictions on long-distance transportation of biomass resources, and increased density of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a preparation method of biomass briquette, comprising the following steps:

[0031] After mixing forest waste particles, rice husk powder, broken cotton stalk particles, coal powder, diatomaceous earth, coal tar, sodium carboxymethyl cellulose and a sulfur-fixing agent, press molding to obtain biomass briquette fuel.

Embodiment 1

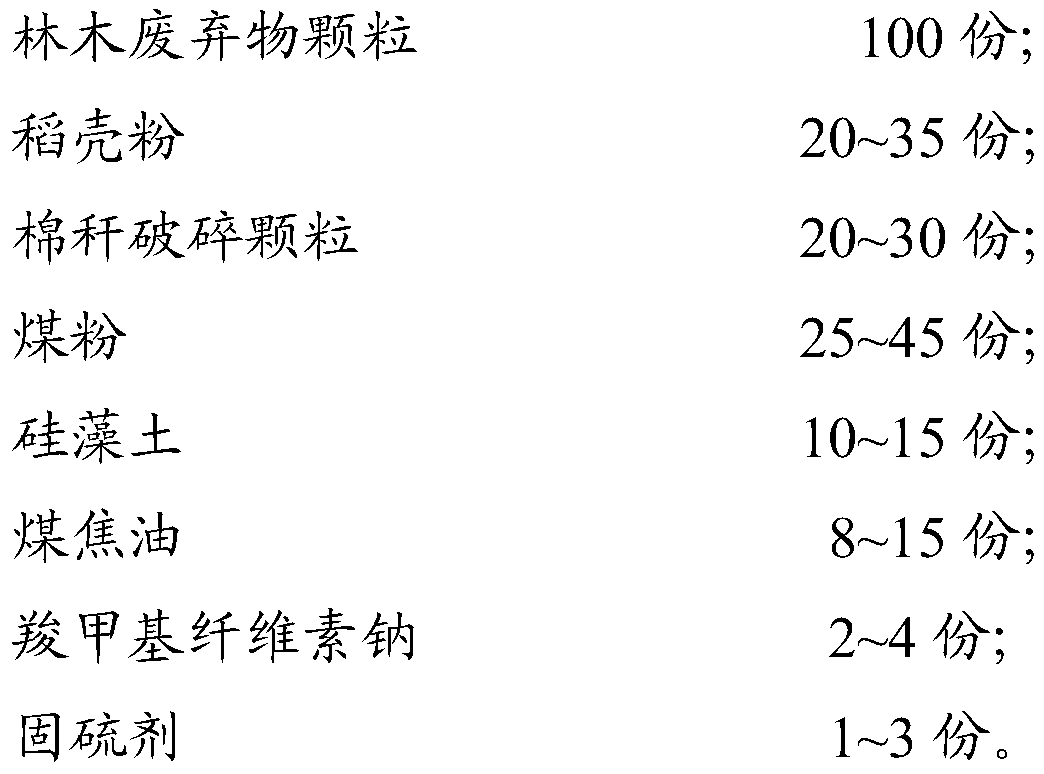

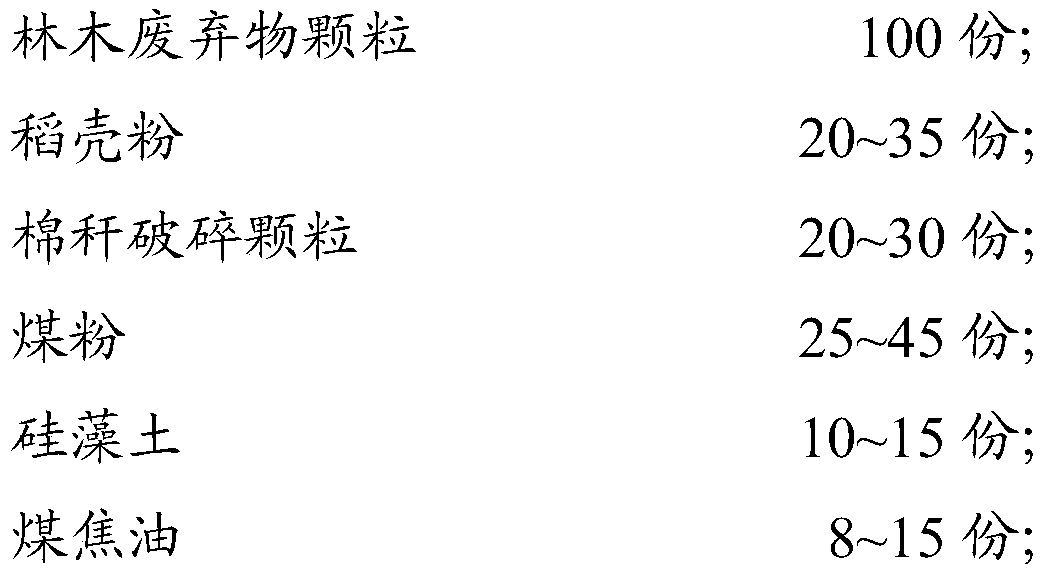

[0034] Mix the following components in parts by mass and press them to obtain biomass briquettes:

[0035] 100 parts of forest waste particles with an average particle size of 1 mm and a moisture content of 12 wt.%, 20 parts of rice husk powder with an average particle size of 2 mm and a moisture content of 10 wt.%, with an average particle size of 6 mm and a moisture content of 10 wt. 30 parts of broken cotton stalk particles, 25 parts of pulverized coal with an average particle size of 1 mm, 15 parts of diatomite with an average particle size of 2 mm, 15 parts of coal tar; 2 parts of sodium carboxymethyl cellulose with an average particle size of 3 parts of 1mm calcium carbonate.

Embodiment 2

[0037] Mix the following components in parts by mass and press them to obtain biomass briquettes:

[0038] 100 parts of forest waste particles with an average particle size of 1 mm and a moisture content of 12 wt.%, 25 parts of rice husk powder with an average particle size of 2 mm and a moisture content of 10 wt.%, with an average particle size of 4 mm and a moisture content of 8 wt. 25 parts of broken cotton stalk particles, 30 parts of pulverized coal with an average particle size of 1.5 mm, 12 parts of diatomite with an average particle size of 1 mm, 10 parts of coal tar; 1 part of 0.5mm calcium carbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com