Clean-burning coal vacuum boiler

A vacuum boiler, clean combustion technology, applied in steam boilers, water-tube steam boilers, steam generation, etc., can solve problems such as environmental pollution, and achieve the effects of reducing pollution, compact design, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

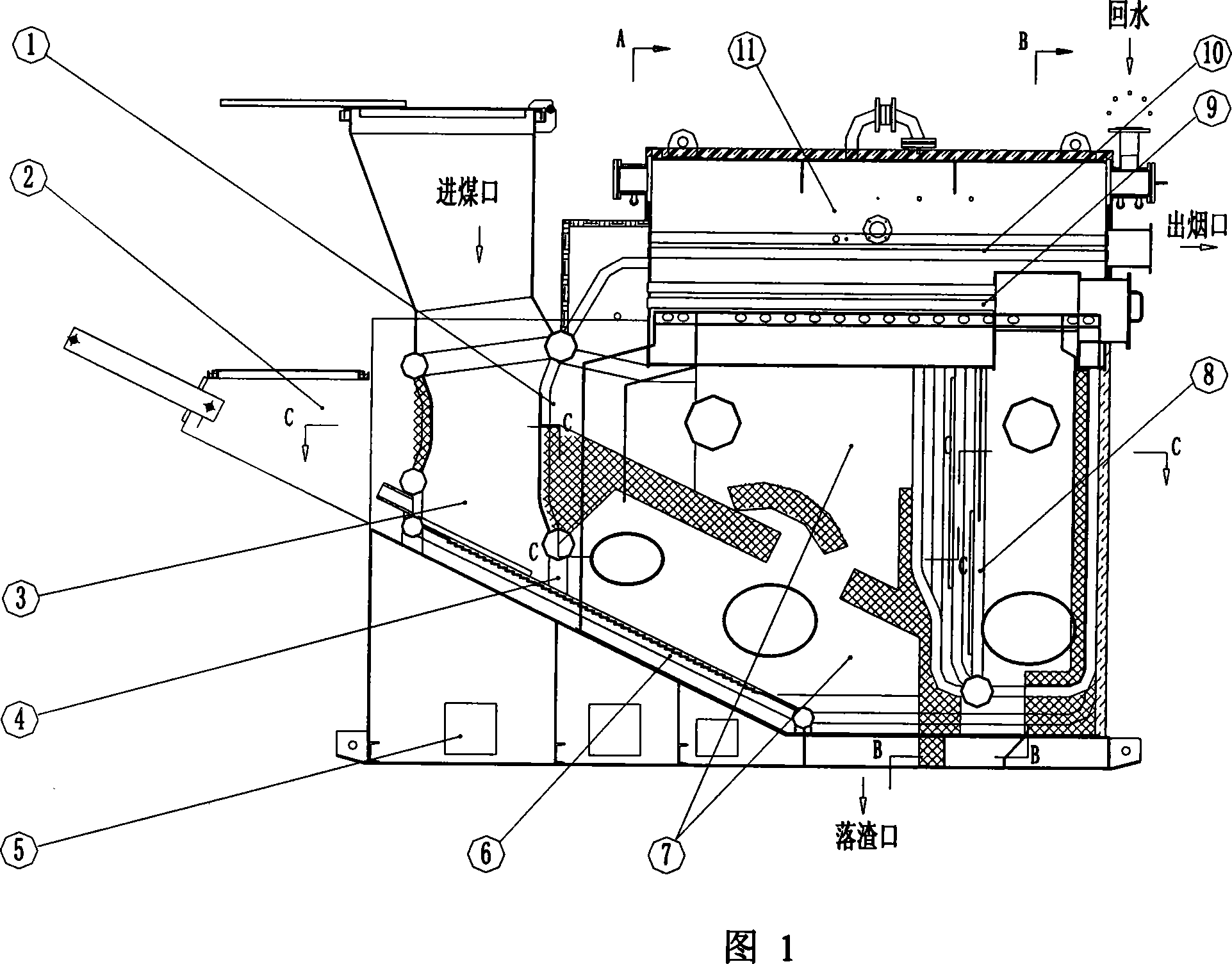

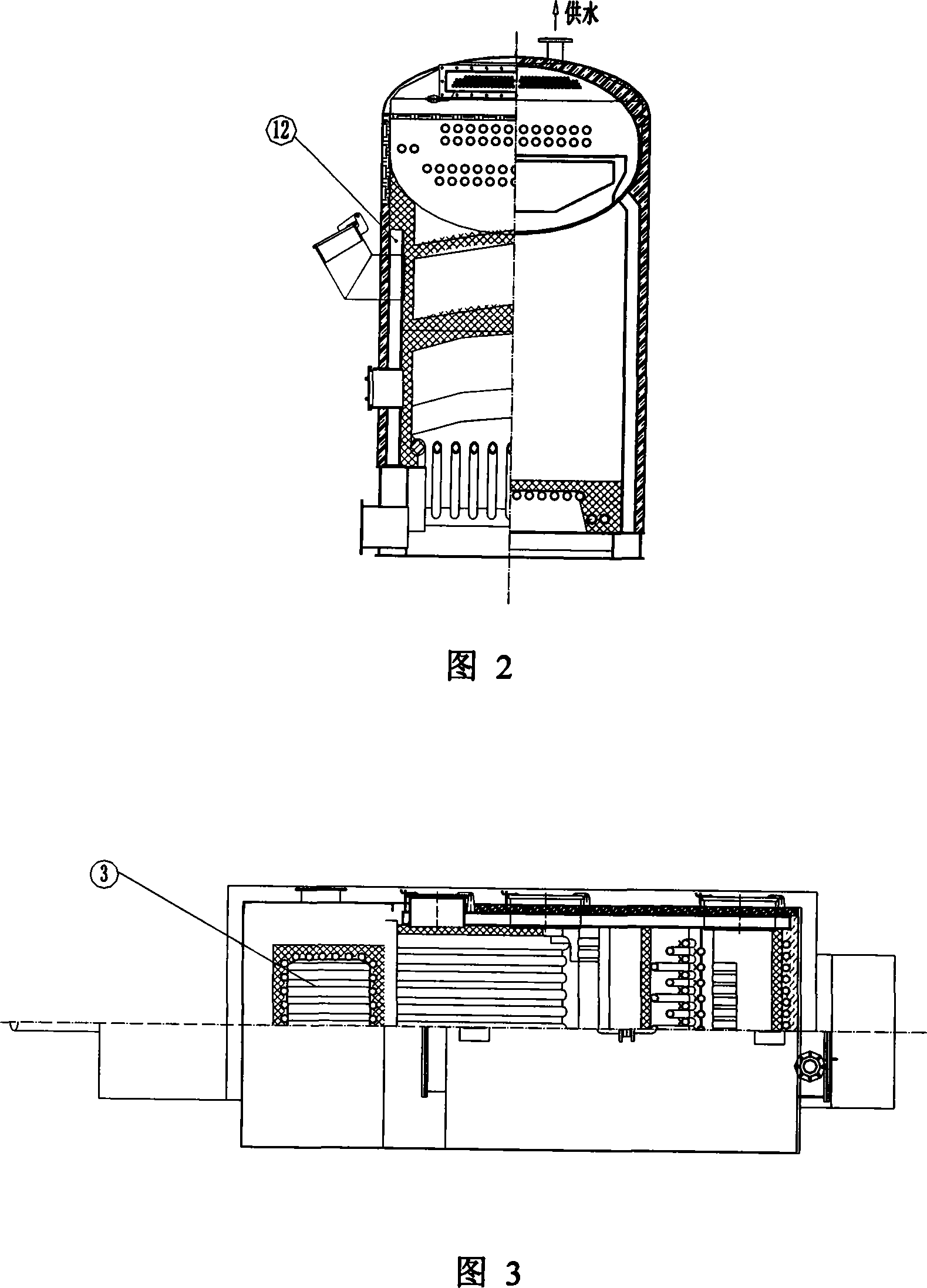

[0028] With reference to accompanying drawing 1, Fig. 2 and Fig. 3.

[0029] The clean combustion coal-fired vacuum boiler includes a furnace body, a drum, and a fire grate. A drum is installed on the upper part of the furnace body, a fire grate is installed on the lower part, and a combustion chamber 7 is located in the middle of the furnace body. The front part of the furnace body combustion chamber 7 is equipped with There is a gas generating chamber 3, the upper part of the gas generating chamber 3 is provided with a gas outlet 1, the gas outlet 1 communicates with the upper part of the combustion chamber, the gas generating chamber 3 communicates with the lower part of the combustion chamber 7, and a fixed water-cooled grate 6 is arranged to burn The outlet of the chamber 7 is arranged with an inertial dedusting type convective water cooling tube bundle 8, and the inertial dedusting type convective water cooling tube bundle 8 is equipped with a dovetail dust removal sheet....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com