Boiler capable of preventing biomass coking

A biomass and coking technology, which is used in the transportation of non-flammable liquids/gases, combustion methods, and combustion of solid fuels, etc., can solve the problems that affect the full combustion of biomass, cannot be burned normally, and affect ventilation, etc., and achieve accurate steam transportation. Fast, avoid the melting point of biomass ash, and enhance the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

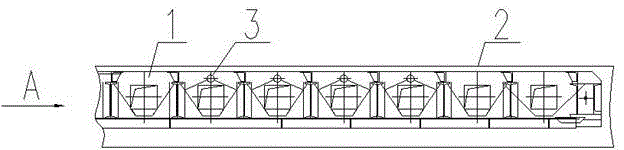

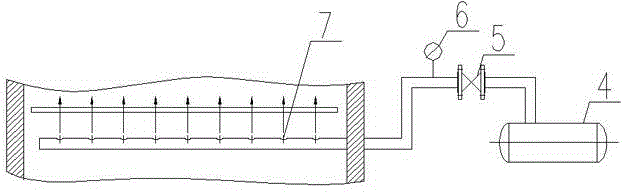

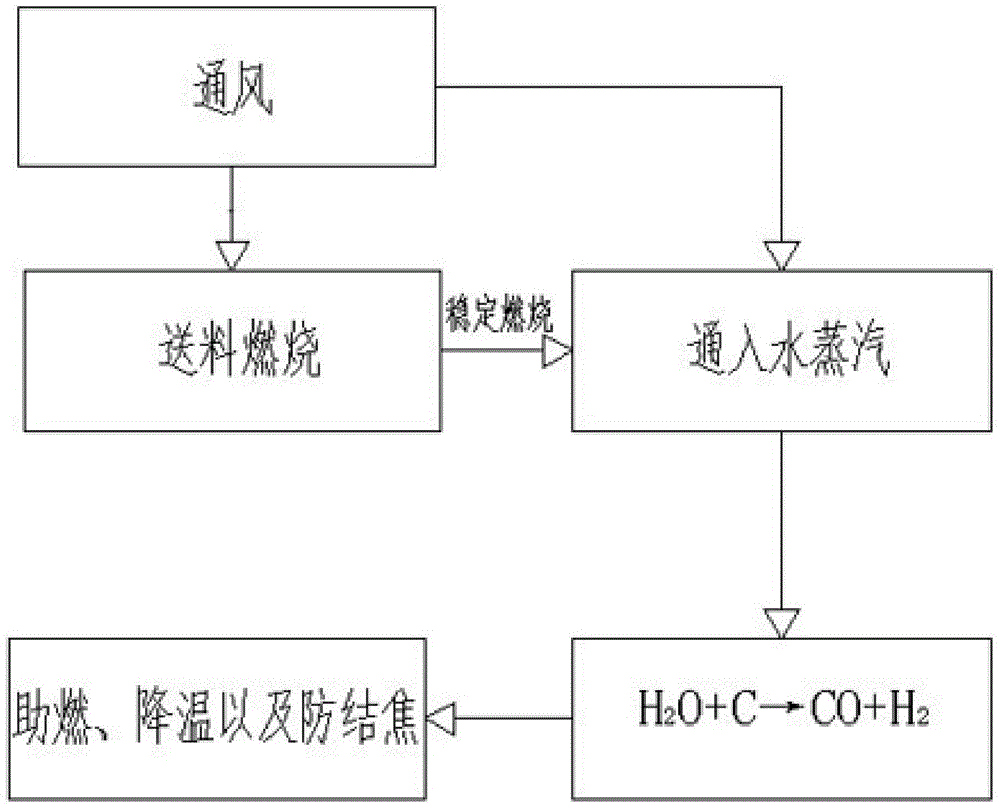

[0026] Such as figure 1 , figure 2 , image 3 As shown, a biomass coking prevention boiler is characterized in that it includes an air distribution chamber, a chain grate, a steam delivery pipeline, a steam distribution cylinder, a pressure reducing valve, a pressure gauge and a steam outlet, and the air distribution chamber is set in Below the chain grate; the steam delivery pipe is set in the middle position above the air distribution elbow in the air distribution chamber, and fixed on the inclined side wallboard of the air distribution chamber through a bracket; the steam delivery pipe is connected to the distribution cylinder through a pressure reducing valve , the steam in the sub-cylinder is regulated by the pressure reducing valve and sent into the air distribution chamber; a pressure gauge is also installed on the steam delivery pipe before entering the air distribution chamber to effectively monitor and adjust the input pressure. The pressure gauge It is arranged a...

Embodiment 2

[0035] Such as figure 1 , figure 2 , image 3 As shown, a biomass coking prevention boiler is characterized in that it includes an air distribution chamber, a chain grate, a steam delivery pipeline, a steam distribution cylinder, a pressure reducing valve, a pressure gauge and a steam outlet, and the air distribution chamber is set in Below the chain grate; the steam delivery pipe is set in the middle position above the air distribution elbow in the air distribution chamber, and fixed on the inclined side wallboard of the air distribution chamber through a bracket; the steam delivery pipe is connected to the distribution cylinder through a pressure reducing valve , the steam in the sub-cylinder is regulated by the pressure reducing valve and sent into the air distribution chamber; a pressure gauge is also installed on the steam delivery pipe before entering the air distribution chamber to effectively monitor and adjust the input pressure. The pressure gauge It is arranged a...

Embodiment 3

[0044] Such as figure 1 , figure 2 , image 3 As shown, a biomass coking prevention boiler is characterized in that it includes an air distribution chamber, a chain grate, a steam delivery pipeline, a steam distribution cylinder, a pressure reducing valve, a pressure gauge and a steam outlet, and the air distribution chamber is set in Below the chain grate; the steam delivery pipe is set in the middle position above the air distribution elbow in the air distribution chamber, and fixed on the inclined side wallboard of the air distribution chamber through a bracket; the steam delivery pipe is connected to the distribution cylinder through a pressure reducing valve , the steam in the sub-cylinder is regulated by the pressure reducing valve and sent into the air distribution chamber; a pressure gauge is also installed on the steam delivery pipe before entering the air distribution chamber to effectively monitor and adjust the input pressure. The pressure gauge It is arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com