Method for combustion adjustment of W-type flame furnace with under-arch secondary air at adjustable down-dip angle

A technology of combustion adjustment and secondary air, which is applied in the direction of combustion method, combustion control, and air supply adjustment. It can solve the problems of high carbon content in fly ash and poor combustion stability, and achieve prolonged residence time, improved stability, and large The effect of reducing the carbon content of slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

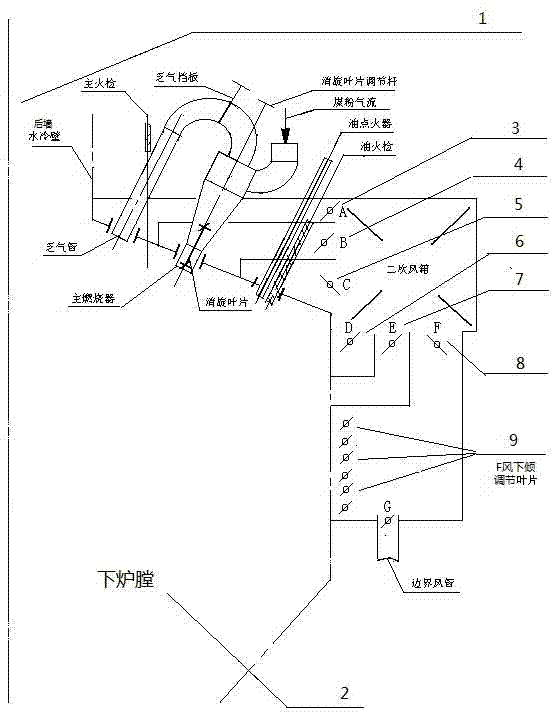

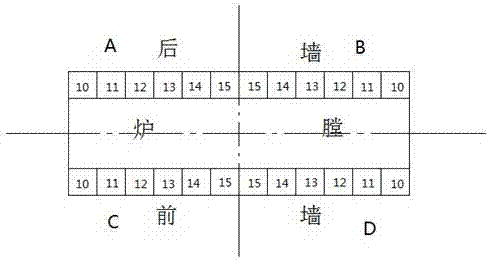

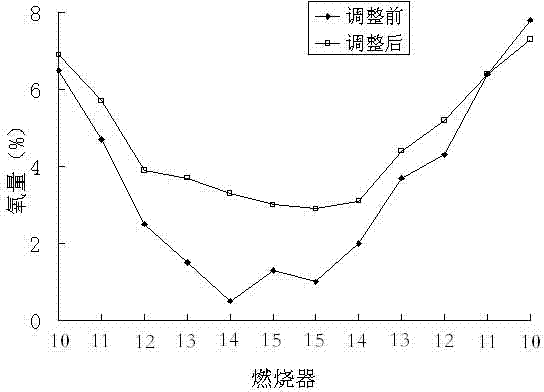

[0022] Embodiment 1: in combination with figure 1Describe this embodiment, this embodiment is realized by the following method: when the boiler is in normal operation, adjust the angle of the secondary air F under the arch to adjust the angle of the blade 9, so that the secondary air under the arch enters the wind direction of the lower furnace 2 to maintain sufficient And proper downward inclination, the downward inclination angle of the blade 9 can be adjusted between 0° and 60°; at the same time, the secondary air under the arch is introduced, and the opening degree of the damper 8 of the secondary air F under the arch is adjusted between 10% and 70%. (average 30-40%), and adopt the adjustment principle of large opening in the middle of the furnace and small opening on both sides; at the same time, the secondary air on the arch is introduced, and the opening of the damper 5 of the secondary air C on the arch is adjusted to 0 ~100%, and adopt the adjustment principle of larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com