Sandwich doughnut cake and preparation method thereof

A production method and technology of donuts, applied in baked food, baking, food science, etc., can solve the problems that ordinary enterprises are difficult to actually produce, cannot meet the intake requirements, and the production process is complicated, so as to improve production efficiency and formula Diverse, Nutritious Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

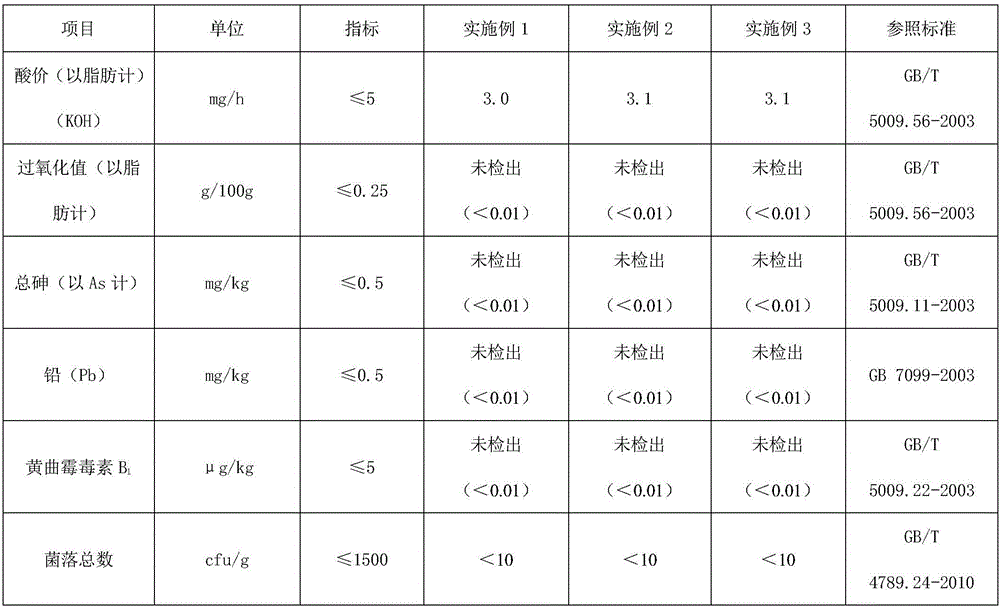

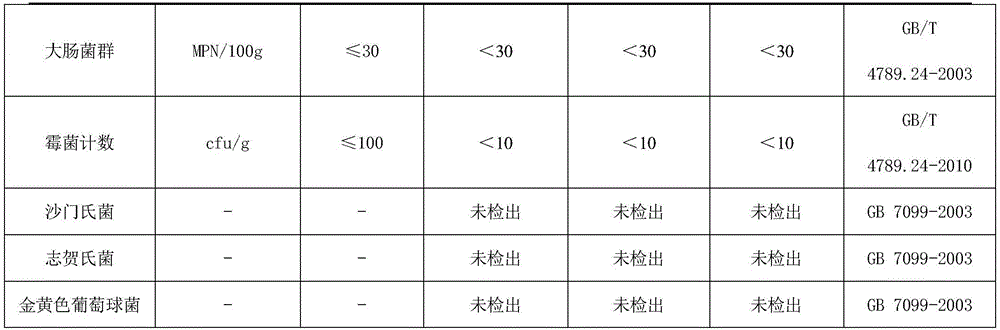

Examples

Embodiment 1

[0044] The sandwich donut cake is characterized in that it comprises the following raw materials in terms of mass parts: 22 parts of medium-gluten wheat flour, 19 parts of white granulated sugar, 4 parts of water, 18 parts of refined vegetable oil, 25 parts of fresh eggs, 5 parts of cornstarch, edible 1 part of salt, 0.5 part of double-acting baking powder, 0.1 part of citric acid, 0.05 part of flavoring, 2 parts of custard sauce, 5 parts of coated chocolate, 0.2 part of chocolate sauce, 0.04 part of sorbitol liquid, 0.04 part of glycerin, Xanthan gum 0.04 part, cake oil 0.10 part.

[0045] Wherein, the coated chocolate includes the following raw materials in parts by mass: 43 parts of cocoa butter substitute, 33 parts of cocoa powder, 49 parts of milk powder, and 1 part of lecithin.

[0046] The preparation method of described coating chocolate comprises the steps:

[0047] Step 1, prepare the following raw materials according to the following mass parts: 43 parts of cocoa b...

Embodiment 2

[0066] Sandwich donut cake, including the following raw materials in parts by mass: 22 parts of medium-gluten wheat flour, 20 parts of white sugar, 5 parts of water, 20 parts of refined vegetable oil, 25 parts of fresh eggs, 5 parts of cornstarch, 1 part of edible salt, 0.7 parts of double-effect baking powder, 0.1 parts of citric acid, 0.10 parts of flavoring, 4 parts of custard sauce, 5 parts of coated chocolate, 0.3 parts of chocolate sauce, 0.04 parts of sorbitol liquid, 0.04 parts of glycerin, and 0.04 parts of xanthan gum part, cake oil 0.12 part.

[0067] Wherein, the coated chocolate includes the following raw materials in parts by mass: 45 parts of cocoa butter substitute, 35 parts of cocoa powder, 50 parts of milk powder, and 2 parts of lecithin.

[0068] The preparation method of described coating chocolate comprises the steps:

[0069] Step 1, prepare the following raw materials according to the following mass parts: 45 parts of cocoa butter substitute, 35 parts o...

Embodiment 3

[0088] Sandwich donut cake, including the following raw materials in terms of mass parts: 23 parts of medium-gluten wheat flour, 22 parts of white sugar, 6 parts of water, 21 parts of refined vegetable oil, 26 parts of fresh eggs, 6 parts of cornstarch, 2 parts of edible salt, 0.8 parts of double-effect baking powder, 0.2 parts of citric acid, 0.15 parts of flavoring, 6 parts of custard sauce, 6 parts of coated chocolate, 0.5 parts of chocolate sauce, 0.06 parts of sorbitol liquid, 0.05 parts of glycerin, and 0.05 parts of xanthan gum part, cake oil 0.15 part.

[0089] Wherein, the coated chocolate includes the following raw materials in parts by mass: 46 parts of cocoa butter substitute, 36 parts of cocoa powder, 52 parts of milk powder, and 3 parts of lecithin.

[0090] The preparation method of described coating chocolate comprises the steps:

[0091] Step 1, prepare the following raw materials according to the following mass parts: 46 parts of cocoa butter substitute, 36 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com