High efficiency coring method for portable drilling machine in integral hard rock

A portable, drilling rig technology, used in earthwork drilling, extraction of undisturbed core devices, construction, etc., can solve the problems of rapid drill bit wear, low core extraction rate, etc., to achieve high reuse rate, strong continuity, and improve the success of extraction. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

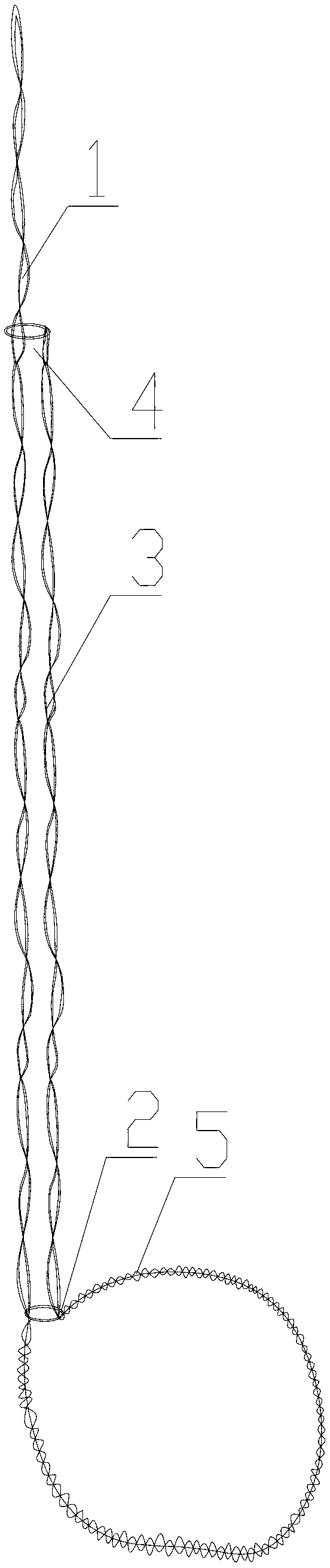

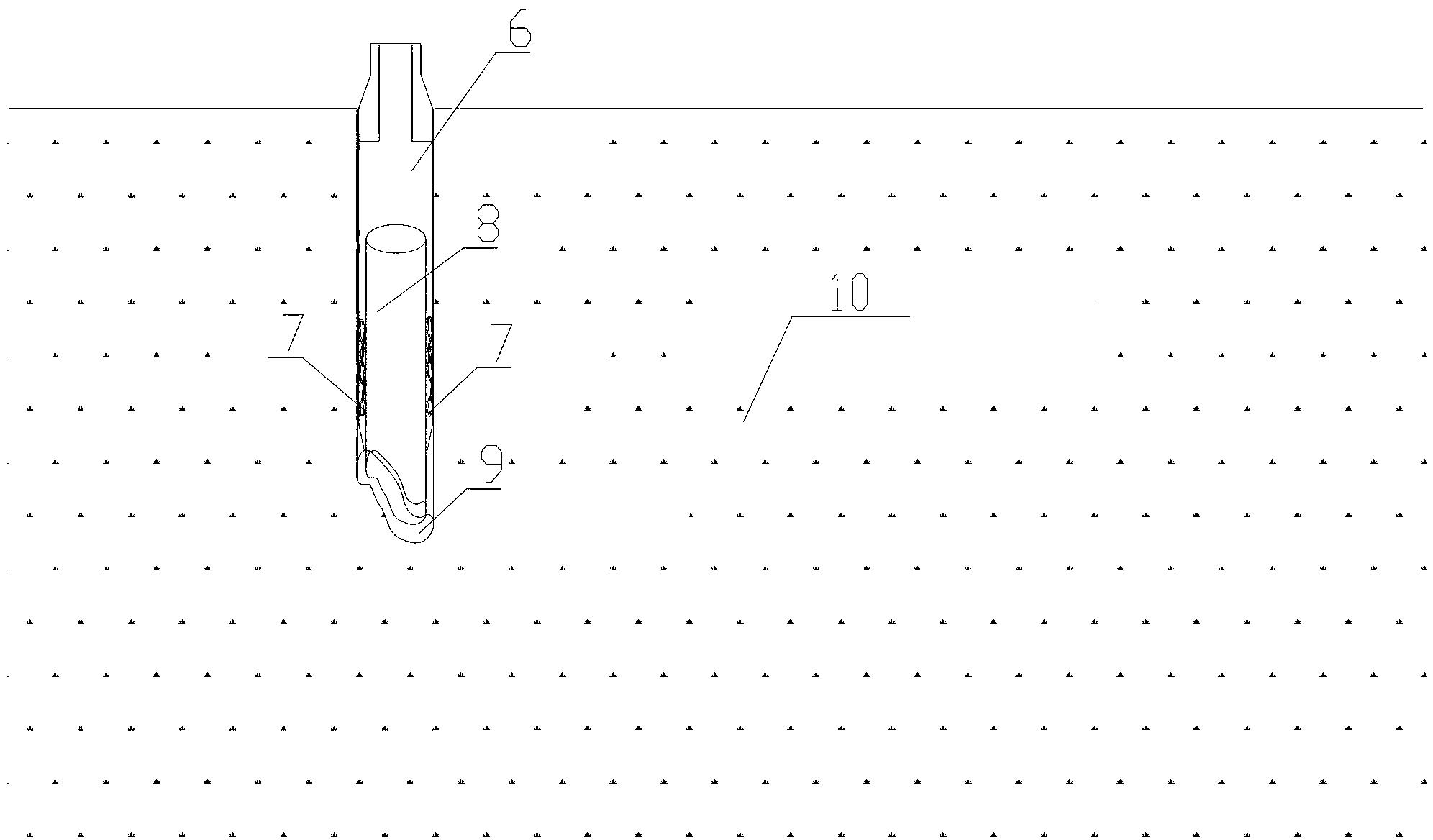

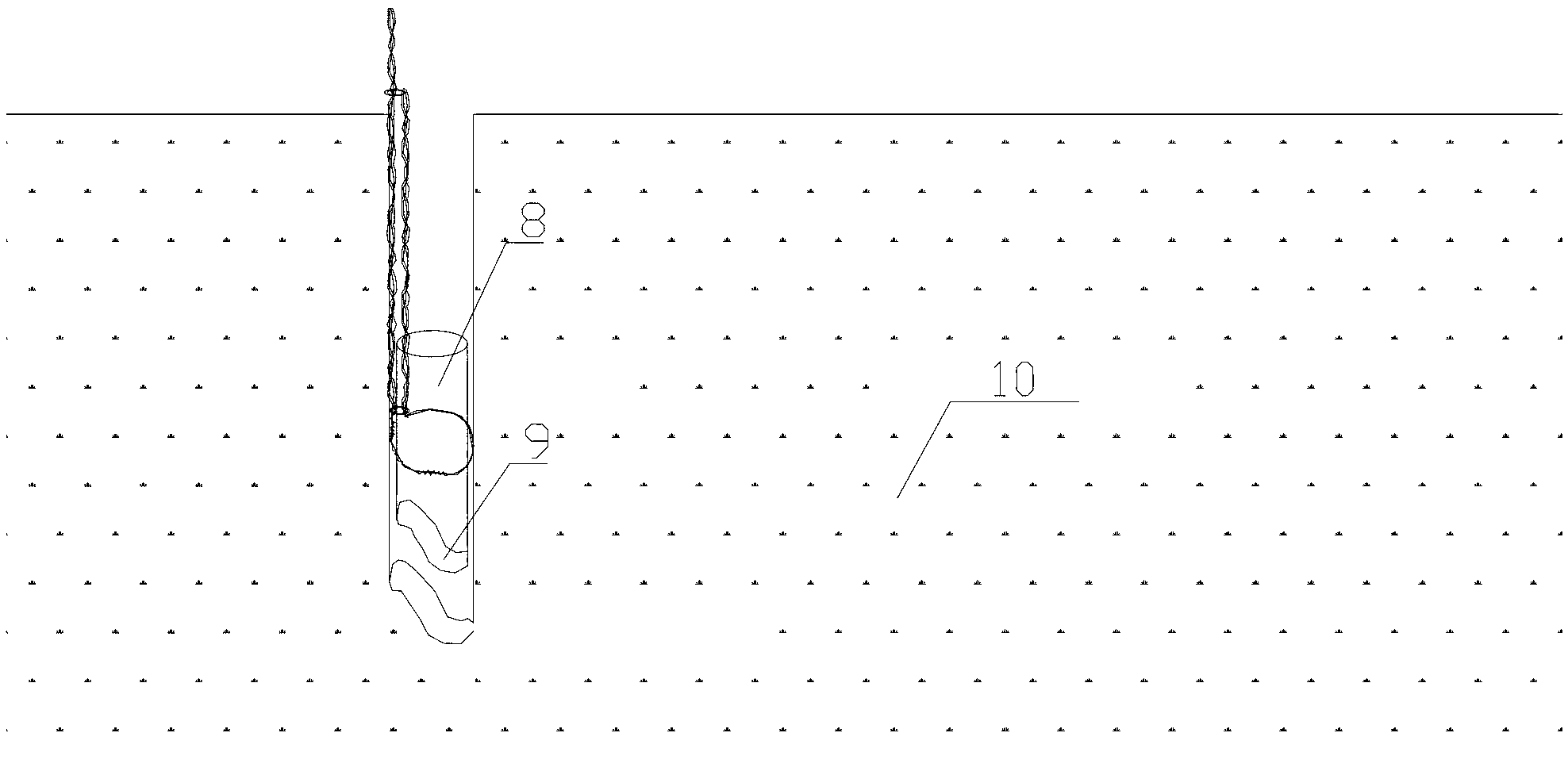

[0028] In order to make the content of the present invention more obvious and understandable, the following in conjunction with the attached figure 1 - attached Figure 4 and specific implementation methods for further description.

[0029] An efficient coring method for a portable drilling rig in a complete hard rock of the present invention comprises the following steps:

[0030] a. In the shallow layer of the surface where the rock core is to be taken, drill a blind hole with a drilling rig, and remove the broken rock core in the blind hole; the depth of the blind hole is 80-100cm.

[0031] B. Lengthen the drill pipe on the drilling rig described in step a, and continue to drill into the lower floor on the basis of the blind hole; when the hollow drill bit at the end of the drill pipe is filled with a complete rock core, stop drilling;

[0032] c. Lift the drill pipe in step b upward slightly, so that a gap of 0.5-1cm is left between the inner wall of the hollow drill bit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com