Plant extract extraction equipment based on cosmetic production

A plant extract and extraction equipment technology, which is applied in the field of plant extract extraction equipment based on cosmetic production, can solve the problems of low effective conversion rate, waste, and long extraction time, and achieve the effect of improving the extraction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

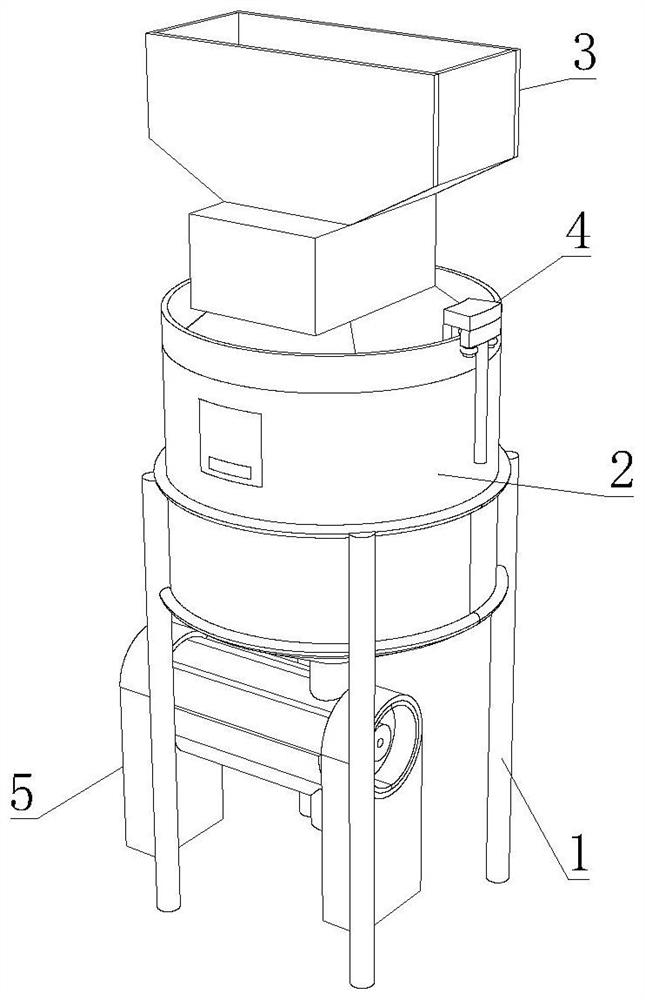

[0034] like Figure 1-5 As shown, the present invention provides a plant extract extraction equipment based on cosmetic production, comprising a support frame 1, an extraction tank 2 is fixedly connected to the inner side of the support frame 1, and an ultrasonic extraction mechanism 4 is fixedly connected to the upper side of the extraction tank 2, The ultrasonic extraction mechanism 4 includes an ultrasonic generator 48 and a rolling mechanism 47, the upper side of the ultrasonic generator 48 is fixedly connected with an outer plate 45, the rolling mechanism 47 includes a rolling wheel 474, and the upper side of the extraction tank 2 is fixedly connected with the grinding mechanism 3, The grinding mechanism 3 includes a grinding wheel 311, the middle of the grinding wheel 311 is fixedly connected with a connecting column 310, the lower side of the extraction tank 2 is fixedly connected with a filtering mechanism 5, and the filtering mechanism 5 includes a metal filter screen ...

Embodiment 2

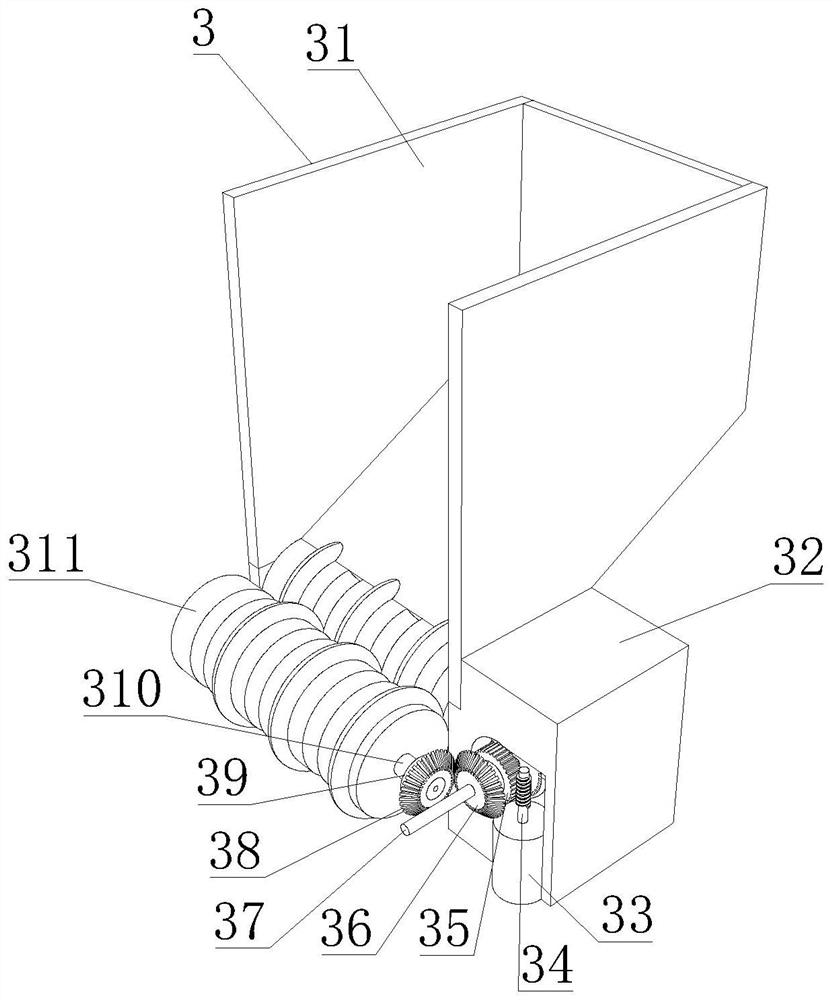

[0037] like Figure 1-5As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the bearing 39 is fixedly installed on the outer surface of the connecting column 310, the grinding shell 32 is fixedly installed on the outer surface of the bearing 39, and the outer surface of the bearing 39 is fixedly installed. The front side is overlapped with a third-stage bevel gear 38, the middle of the third-stage bevel gear 38 is fixedly installed with the outer surface of the connecting column 310, and the outer side of the third-stage bevel gear 38 is movably connected with a second-stage bevel gear 36. A central shaft 37 is fixedly installed in the middle, a secondary gear 35 is fixedly installed in the middle of the outer surface of the central shaft 37, a screw rod 34 is movably connected to the outer side of the secondary gear 35, and a servo motor 33 is fixedly connected to the lower end of the screw rod 34 for grinding. The interior ...

Embodiment 3

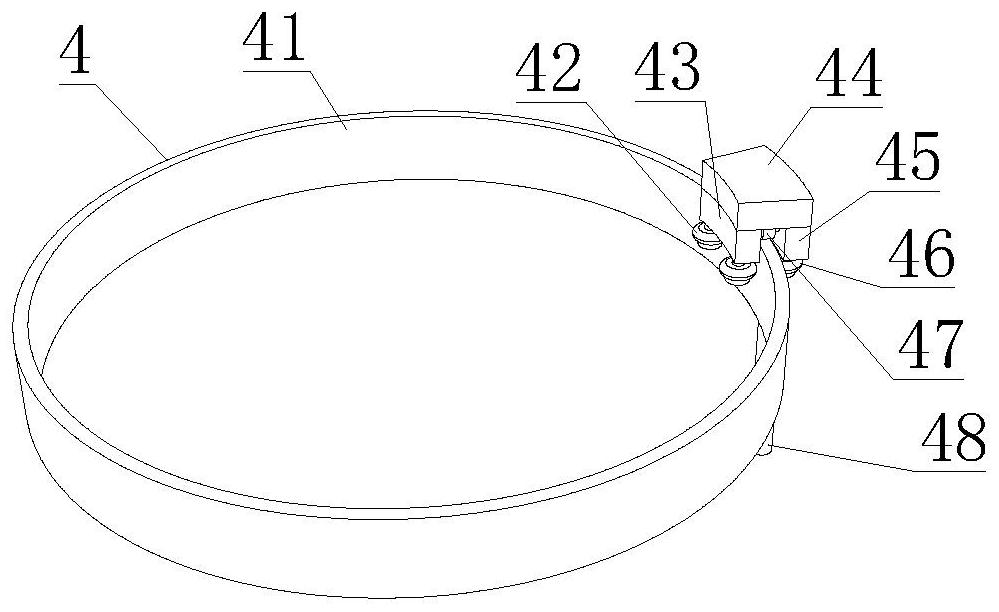

[0040] like Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, an upper cover 44 is fixedly connected to the upper side of the outer plate 45, and an inner plate 43 is fixedly connected to the lower side of the upper cover 44. The lower side of 43 is rotatably connected with the inner wheel 42, the lower side of the outer plate 45 is fixedly connected with the outer wheel 46, the outer surface of the inner wheel 42 is rollingly connected with the track plate 41, and the outer side of the track plate 41 is rollingly connected with the outer surface of the outer wheel 46, The left end of the rolling wheel 1 474 is rotatably connected with the interior of the inner plate 43 , the right end of the rolling wheel 1 474 is rotatably connected with the interior of the outer plate 45 , the upper side of the inner plate 43 is fixedly connected with a servo motor two 471 , and the right end of the servo motor two 471 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com