Automatic bolt conveying device for high-altitude construction operation machine

A technology for working machinery and high-altitude construction, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of time-consuming and labor-consuming bolt transportation, and achieve the effect of avoiding manual loading of bolts, improving the degree of mechanization, and accurate steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

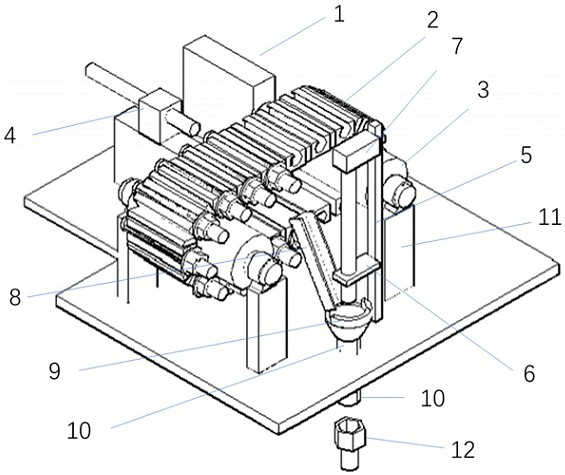

[0018] Example 1, such as figure 1 As shown, the automatic bolt conveying device for a high-altitude construction operation machine according to the present invention includes a bracket 11, and two sets of four support platforms are arranged on the support 11. The upper ends of the four support platforms are connected with two crawler belts through bearing rotation. Cylinder 3, the two crawler drums 3 are provided with bolt conveying crawlers. When in use, bolts are placed on the bolt conveying crawlers, and the bolts are conveyed through the bolt conveying crawlers; One of the crawler drums 3 is connected, and the driving mechanism 1 is a rotating shaft stepping motor. The driving mechanism 1 drives the rotation of the crawler drum 3 to drive the rotation of the bolt conveyor belt, thereby conveying the bolts and improving the mechanization of bolt conveying. The support 11 is also provided with a push-out mechanism 4 that pushes out the bolts on the bolt conveying track, and...

Embodiment 2

[0023] The difference between embodiment 2 and embodiment 1 is that a socket wrench 11 is provided in cooperation with the sliding sleeve 10 , and the socket wrench 11 is located directly below the sliding sleeve 10 to catch the bolts falling from the sliding sleeve 10 . The socket wrench 11 is connected with a tool changing mechanism (shown in the figure), which is an existing tool changing mechanism in the prior art, and its structure will not be repeated here. The socket wrench with the bolt is moved to the operation point through the tool change mechanism for construction. The bolt can be a round bolt or a hexagonal helix, and the hole of the socket wrench fits the bolt.

Embodiment 3

[0024] Embodiment 3, its difference from Embodiment 2 is that the bolts are hexagonal bolts, and the bracket 11 is provided with a positive position mechanism for the bolts in the rotating slide 10 so that the six faces of the bolts are aligned with the socket wrench 11 The hexagonal hole fits, and the positive position mechanism is located above the sliding cylinder 10 and the funnel 9 and corresponds to the sliding cylinder 10.

[0025] Preferably, the positive position mechanism includes a screw motor 7, the screw motor 7 is mobile connected with the bracket 11 through the lifting track 5, the lifting track 5 is vertically fixed on the bracket 11, and the middle and lower part of the lifting track 5 is connected with a horizontal extension Out of the screw shaft plate 6, the screw of the screw motor 7 is meshed with the screw shaft plate 6, and the screw of the screw motor 7 is coaxially arranged with the sliding cylinder 10. Specifically, the screw shaft plate 6 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com