Patents

Literature

92results about How to "Ease of environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry distillation production process for lignite or high volatile coal

InactiveCN101885973AReduce the temperatureQuality improvementDirect heating destructive distillationHeat carrierTar

The invention discloses a dry distillation production process for lignite or high volatile coal. A high-temperature dry distillation gas serving as a heat carrier enter a dry distillation furnace to transmit heat with coal inside the furnace by contact to change the coal into semicoke through pyrolysis and dry distillation; the gas overflowing through the dry distillation flows into a heat carrier gas and then out of the furnace together; after the gas from the furnace is cooled and purified, which is equivalent to that a part of the original heat carrier gas is heated through a partition to a high temperature to serve as a heat carrier to return to the dry distillation furnace for recycling; and the balance of gas serves as an external supply. The dry distillation production process has the advantages of both internal and external heat dry distillation and obtains the approximately same gas purity as that of the external heat dry distillation process, so that the gas for the externalsupply has a high quality, heat value and application value and is an ideal chemical raw material or high-quality fuel; moreover, all the dry distillation gas can be used for the external supply; thecoal is slightly affected by a temperature and uniformly heated; tar has a high yield; the system has a wide heat source and can use low-quality fuel smoke, such as powdered coal, the gas and the like; and the system has a simple flow, is easy to operate and control in production and operation and has less industrialization construction investment.

Owner:NANTONG JINGHUAN ENERGY TECH CO LTD

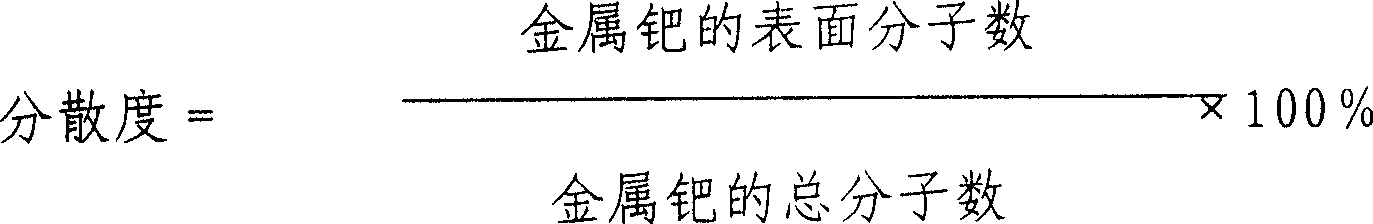

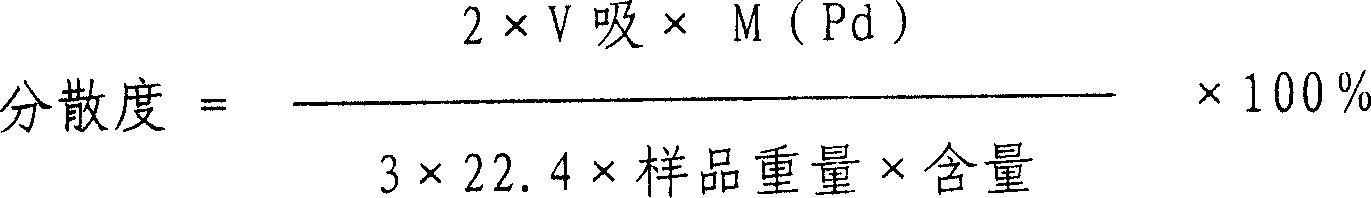

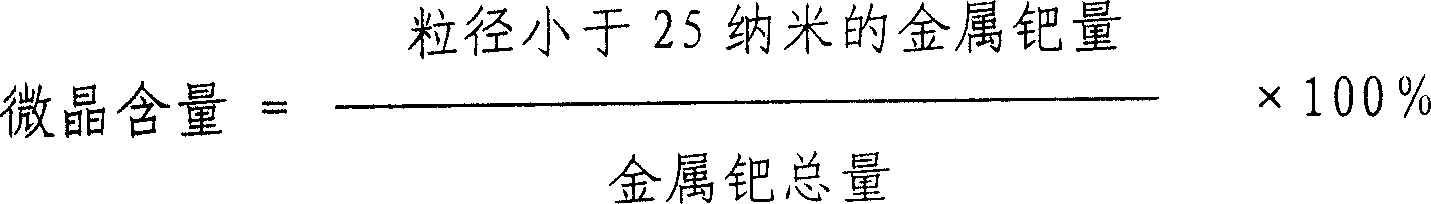

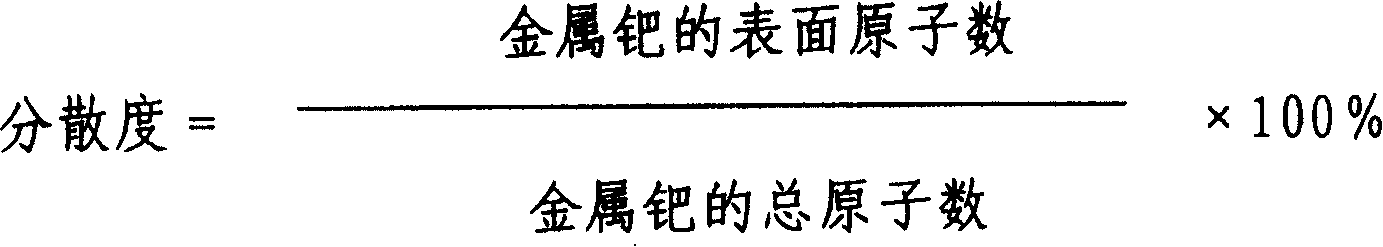

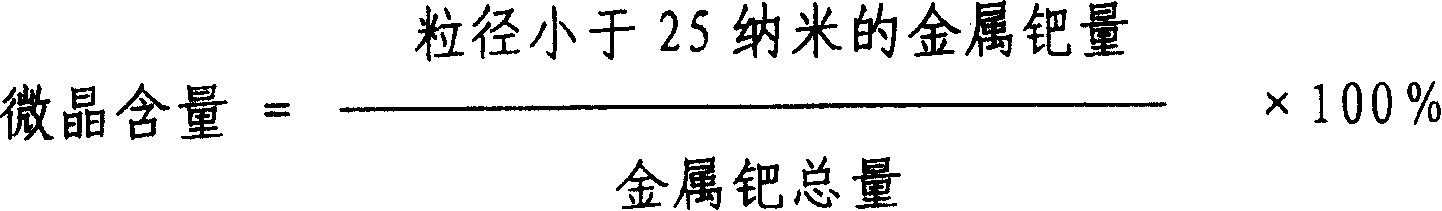

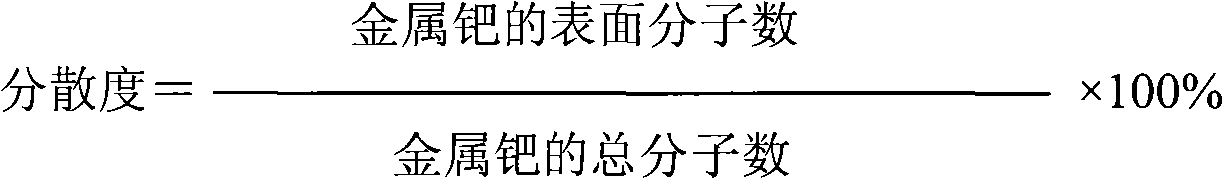

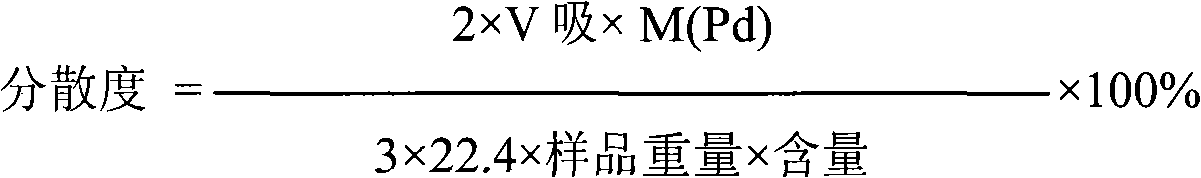

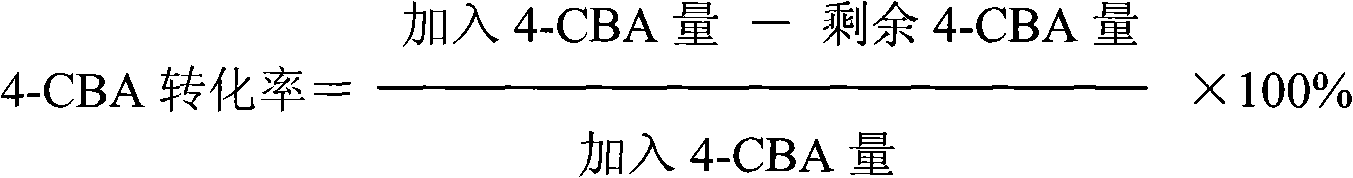

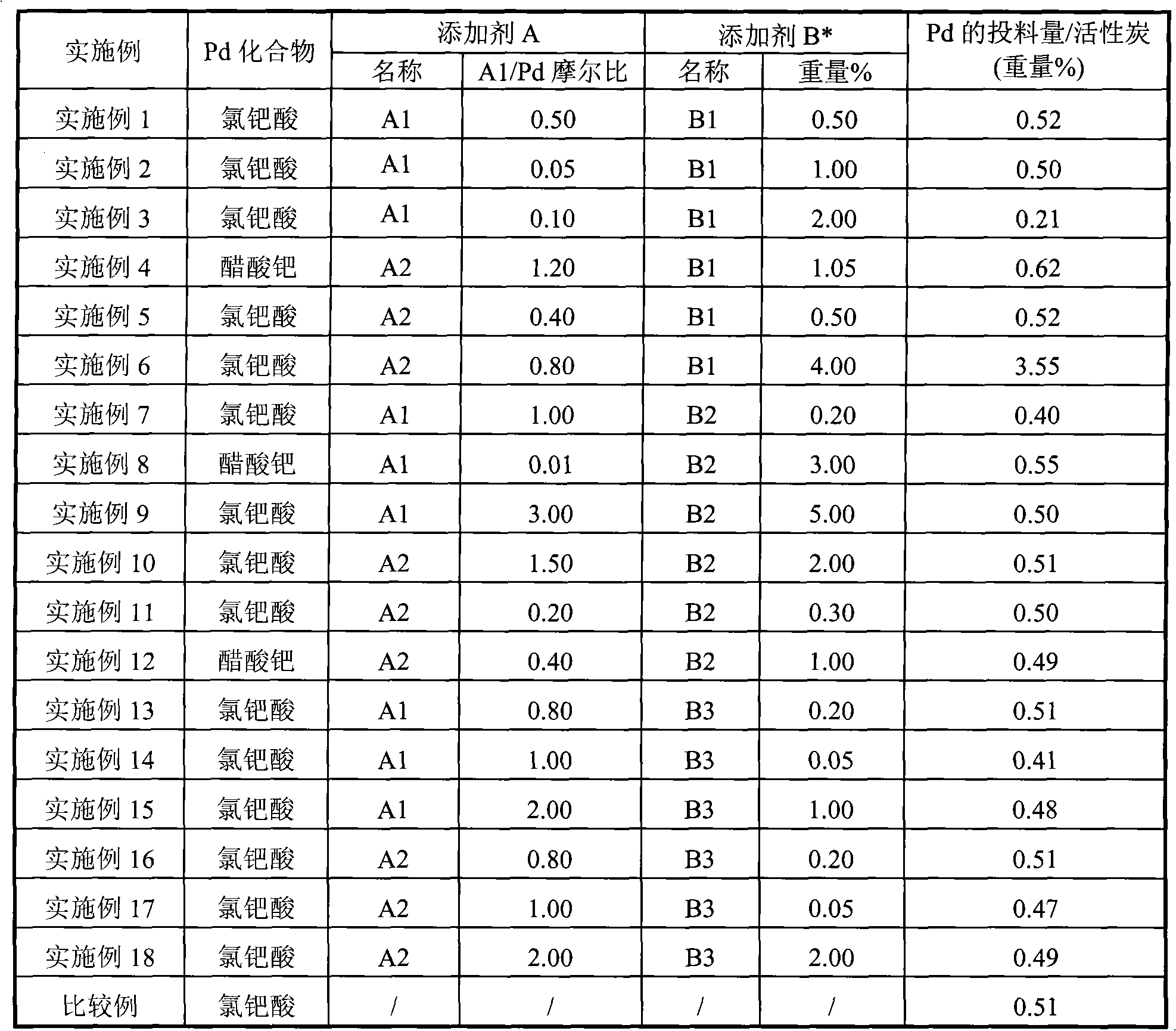

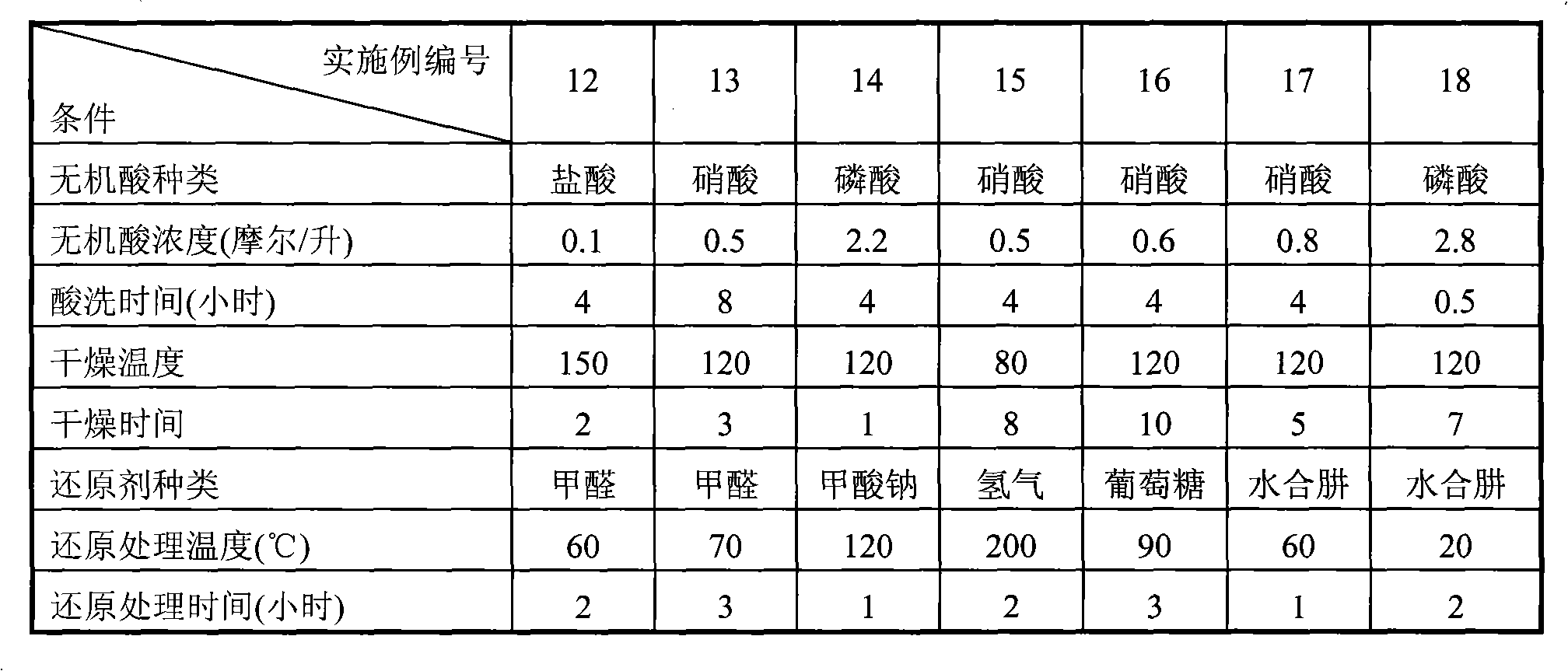

Method for preparing palladium/carbon catalyzer by hydrogenising and refining crude terephthalic acid

InactiveCN1565726AGood dispersionHigh microcrystalline contentOrganic compound preparationCarboxylic compound preparationNitrite ionPhosphoric acid

A method for preparing Pd / C catalyst for selective hydrogenation is provided. The content of Pd in catalyst is 0.2 to 5% by weight. The preparing process includes the following steps: active carbon carrier is washed by 0.1 to 5N concentration of acid washing liquid selected from hydrochloric acid, nitric acid or phosphoric acid; active carbon carrier is washed to neutrality by water and dried; the active carbon carrier is soaked in nitrite ion containing solution for 2 to 24 hours and dried; the Pd compound is sprayed on the active carbon carrier to form catalyst precursor, after aging and reduction process, the catalyst product is obtained. Metal Pd in catalyst has higher dispersion degree and the content of crystallite is very high.

Owner:CHINA PETROLEUM & CHEM CORP

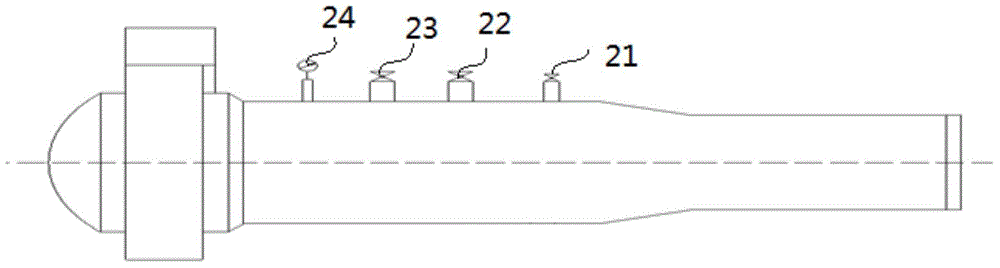

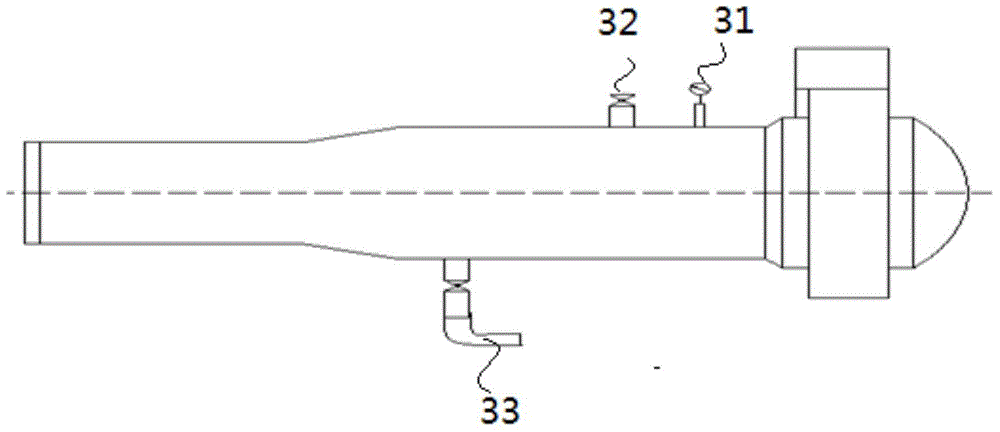

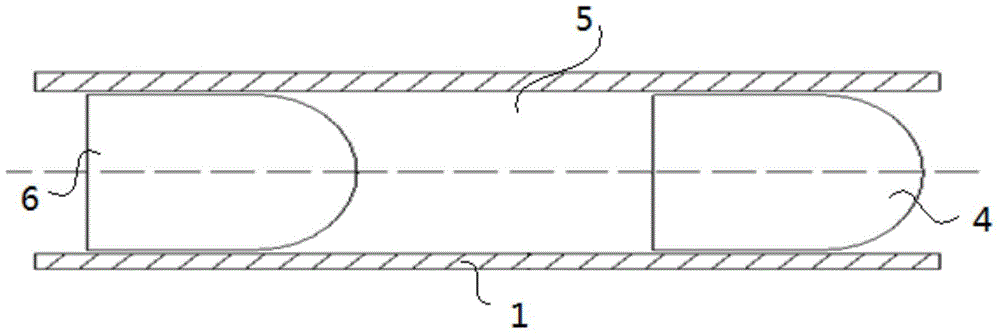

Pollution-free, high-efficiency and long-distance pipe installing and cleaning method

ActiveCN104307822AGood degreasing effectShort construction periodNon-ionic surface-active compoundsOrganic detergent compounding agentsAlkylphenolEngineering

The invention discloses a pollution-free, high-efficiency and long-distance pipe installing and cleaning method, and belongs to the field of pipe cleaning. The pollution-free, high-efficiency and long-distance pipe installing and cleaning method comprises the following steps: installing a ball sending device and a ball receiving device, temporarily testing the leakage and the pressure of a system, sending a diameter-measuring ball, drying, derusting, passivating, chemically degreasing, drying, inspecting and accepting, performing nitrogen protection and transferring, wherein in the derusting, passivating and chemically degreasing steps, a pipe-cleaning train of a pipe cleaner-a chemical agent-a pipe cleaner is used, namely the chemical agent is integrally injected into a space between a first pipe cleaner and a second pipe cleaner; the chemical agent comprises a passivating agent or a degreasing agent; the degreasing agent adopts the formulation as follows: 2-3.5% of sodium tripolyphosphate, 1-2% of sodium carbonate, 0.5-1.5% of sodium hydroxide, 0.2-0.4% of sodium borate, 0.1-0.2% of disodium ethylenediamine tetraacetate, 0.05-0.1% of sodium oleate, 0.05-0.1% of sodium dodecyl sulfate, 0.05-0.1% of alkylphenol ethoxylate and 92.1-96.05% of water. By the pollution-free, high-efficiency and long-distance pipe installing and cleaning method, synchronous and high-efficiency operation of physical cleaning and chemical cleaning of a long-distance pipe can be achieved.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

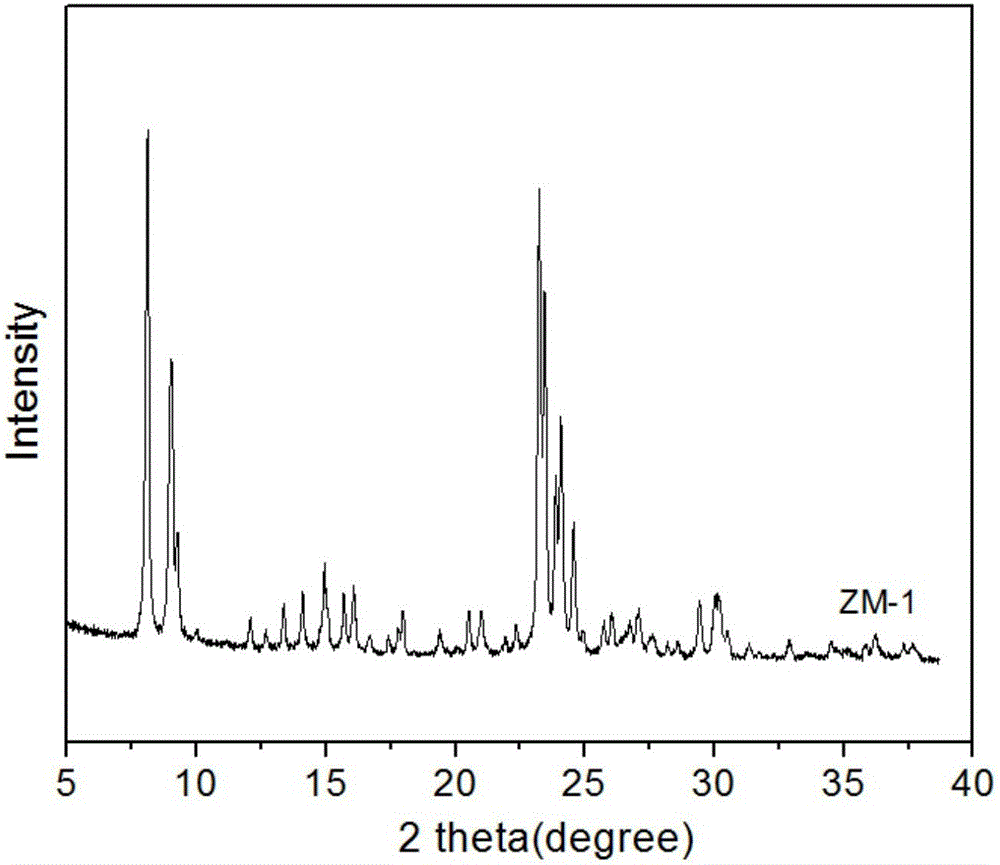

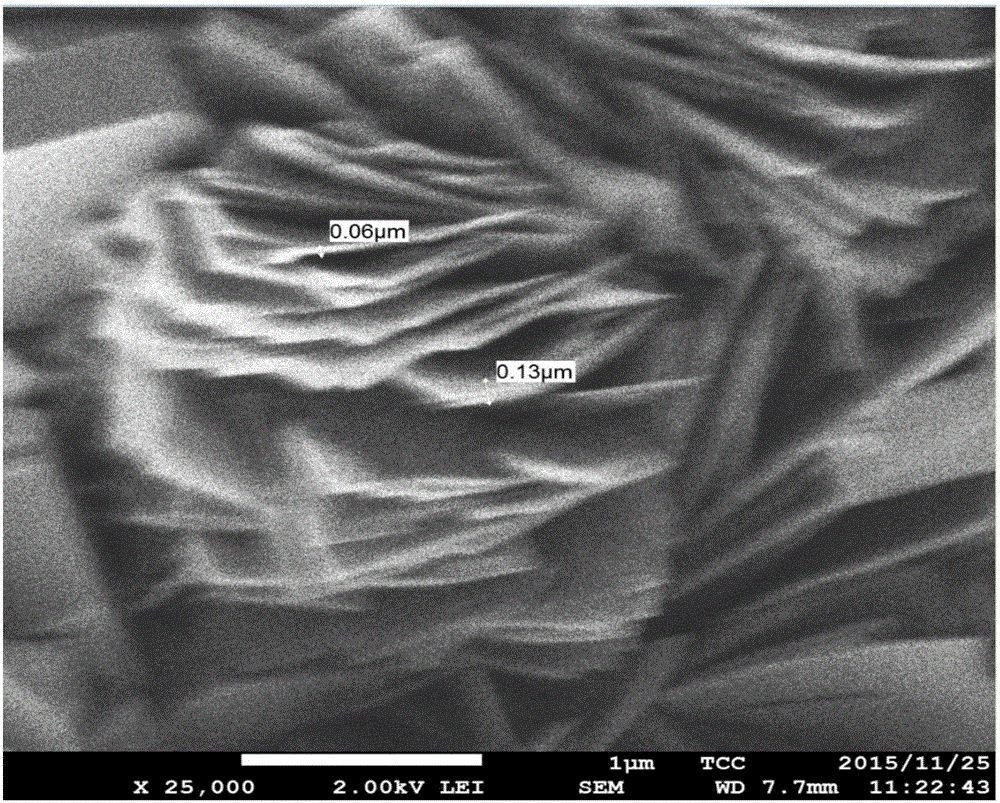

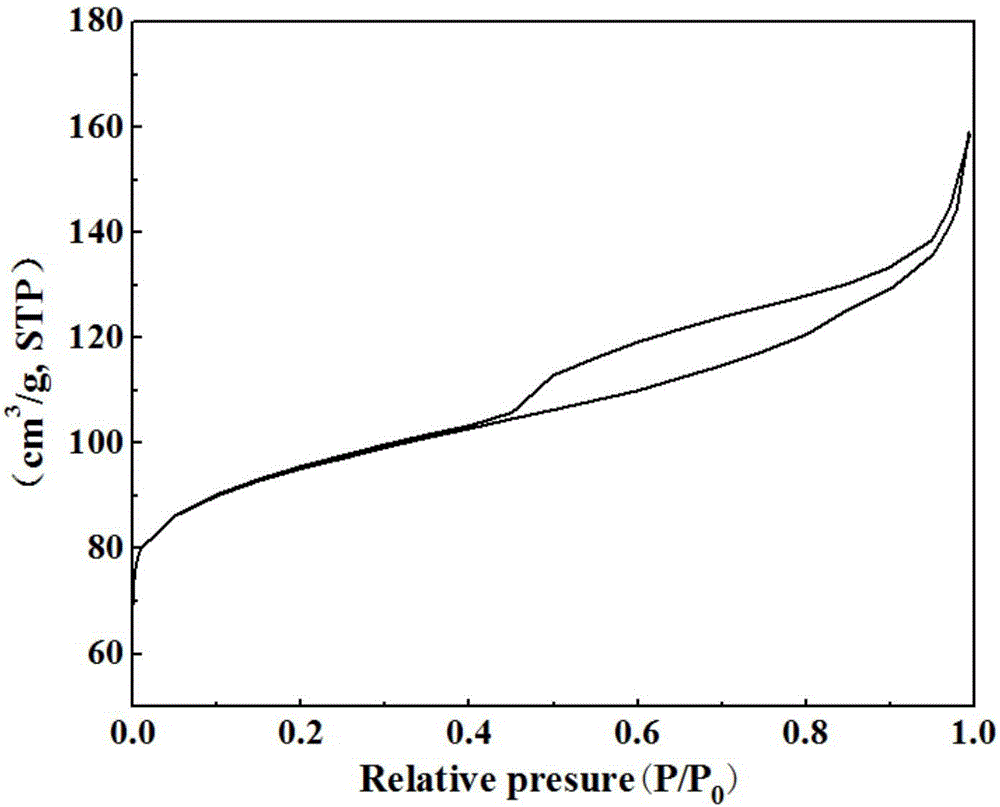

Synthesis method of lamellar ZSM-5 zeolite

ActiveCN106006668ALarge specific surface areaReduce pollutionPentasil aluminosilicate zeoliteSynthesis methodsCrystallinity

The invention provides a synthesis method of lamellar ZSM-5 zeolite. The synthesis method comprises the following steps: crystal seed pretreatment, silica-alumina gel preparation and the like. The synthesized zeolite is a typical MFI structure, has the advantages of high crystallinity and large specific area, has the lamellar shape with the lamellar thickness of 50nm or so, and has favorable application potential in the aspects of high-molecular reaction and the like by using the unique shape and physical property characteristics. Compared with the prior art, the synthesis method does not need any organic template or surfactant, has the advantages of simple synthesis technique operation, lower cost, no environment pollution and the like, and thus, can be popularized and applied in industry.

Owner:CHINA TIANCHEN ENG +1

Method for preparing catalyst for refining of crude terephthalic acid

ActiveCN100402144CLower redox potentialRestore will notOrganic compound preparationCarboxylic compound preparationNitrite ionPhenanthroline

This is a kind of producing method of catalyst used for refining coarse terephthalic acid (CTA). The catalyst makes grains or molding active carbon as carrier, the content of loading active component metal Pd is 0.2 - 4wt%. It orderly includes: have acid wash to carrier active carbon; wash carrier active carbon with water to neutral; have soakage with watery solution containing nitrite ion to carrier active carbon; dry carrier active carbon to get rid of water; prepare Pd solution with water-soluble Pd compound, a kind of complexing agent and water to infuse or insufflate the carrier active carbon; the content of Pd compound in the Pd solution counted by Pd is 15 - 20wt%; the mol proportion of complexing agent and Pd is (0.01 - 1) : 1, the complexing agent is got from anyone of 8-hydroxyquinoline, 2, 3, 4-trihydroxyl-4-sulfonic azobenzol, o-phenanthroline, o-Aminophenol, o-hydroxybenzoic sodium or o-hydroxybenzaldehyde oxime; after aginged, have deoxidizing treatment with reducing agent to get activator products.

Owner:CHINA PETROLEUM & CHEM CORP

Reaction apparatus for resorcinol neutralization reaction section and reaction technology thereof

ActiveCN102329253ASimple structureLow costOrganic compound preparationFlow mixersBenzenePhysical chemistry

The invention which discloses a reaction apparatus for the resorcinol neutralization reaction and a reaction technology thereof relates to a continuous application of a mixer in a resorcinol neutralization reaction section, and concretely relates to a continuous application of a static mixer in the resorcinol neutralization reaction section, so problems of high energy consumption, a large amount of solid wastes and the like existing in present production processes of m-benzene sodium disulfonate can be solved. The reaction technology comprises the following steps: conveying m-benzene disulfonic acid and a liquid alkali to the static mixer through a metering pump; carrying out the neutralization reaction; and carrying out heating and water evaporation on a generated material with heat generated in neutralization to directly form m-benzene sodium disulfonate which has a powder form at a high temperature and is used for an m-benzene sodium disulfonate alkali fusion section. According to the invention, the acid-base neutralization and drying are synchronously carried out, the drying speed is fast, and drying is complete, so a purpose of the continuous production is realized, and simultaneously the energy utilization rate is improved and the generation of the solid wastes is reduced.

Owner:JIANGSU ZHONGDAN CHEM TECH

Method for recovering rare earth La and Ce from FCC dead catalyst

PendingCN111690811AIncrease processing costReduce processing costsProcess efficiency improvementRare-earth elementMetallurgy

The invention relates to a method for recovering rare earth La and Ce from and FCC dead catalyst and mainly solves the problems in the prior art that the FCC dead catalyst can hardly be disposed in anenvironment-friendly manner, disposal cost is high and the recovery rate is low. Through use of the method for recovering the rare earth La and Ce from the FCC dead catalyst, an acid solution is taken as an extracting agent; under a certain temperature and a certain concentration, the acid is used for leaching rare earth elements in the catalyst into the solution, a leaching liquid containing therare earth is obtained, a purified rare earth solution is obtained through removal of Al and Si from the leaching liquid, and then a pure rare earth solution is obtained through extraction and back-extraction. The technical solution effectively solves the above problems and can be used for recovering the rare earth La and Ce from the FCC dead catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing Pd/carbon catalyst for hydrofinishing of coarse isophthalic acid

InactiveCN101347729AGood dispersionHigh microcrystalline contentMetal/metal-oxides/metal-hydroxide catalystsCarboxylic compound separation/purificationNitrite ionActivated carbon

The invention relates to a preparation method of a Pd / C catalyst which is used for hydrogenation refining of crude isophthalic acid, and the preparation method is mainly used for solving the problems of low dispersion of metal Pd and low microcrystal content in the catalyst which is prepared by the prior art. The preparation method firstly carries out the pickling of activated carbon carrier, then uses water or alkali for washing till neutral nature and carries out the drying, water solution containing nitrite ions is further used for infiltration, wherein, the concentration of the nitrite ions is 0.01 to 0.5N, the using amount of infiltration liquid is 0.1 to 3.0 times of the saturated absorption amount of the activated carbon carrier, the infiltration time is 2 to 24 hours; the activated carbon is then used for removing water, Pd compound is impregnated, and a reducing agent is further used for carrying out the reduction to obtain a catalyst product; therefore, the technical proposal can better solve the problems and can be used in the industrial production for hydrogenation refining of the crude isophthalic acid.

Owner:CHINA PETROLEUM & CHEM CORP +1

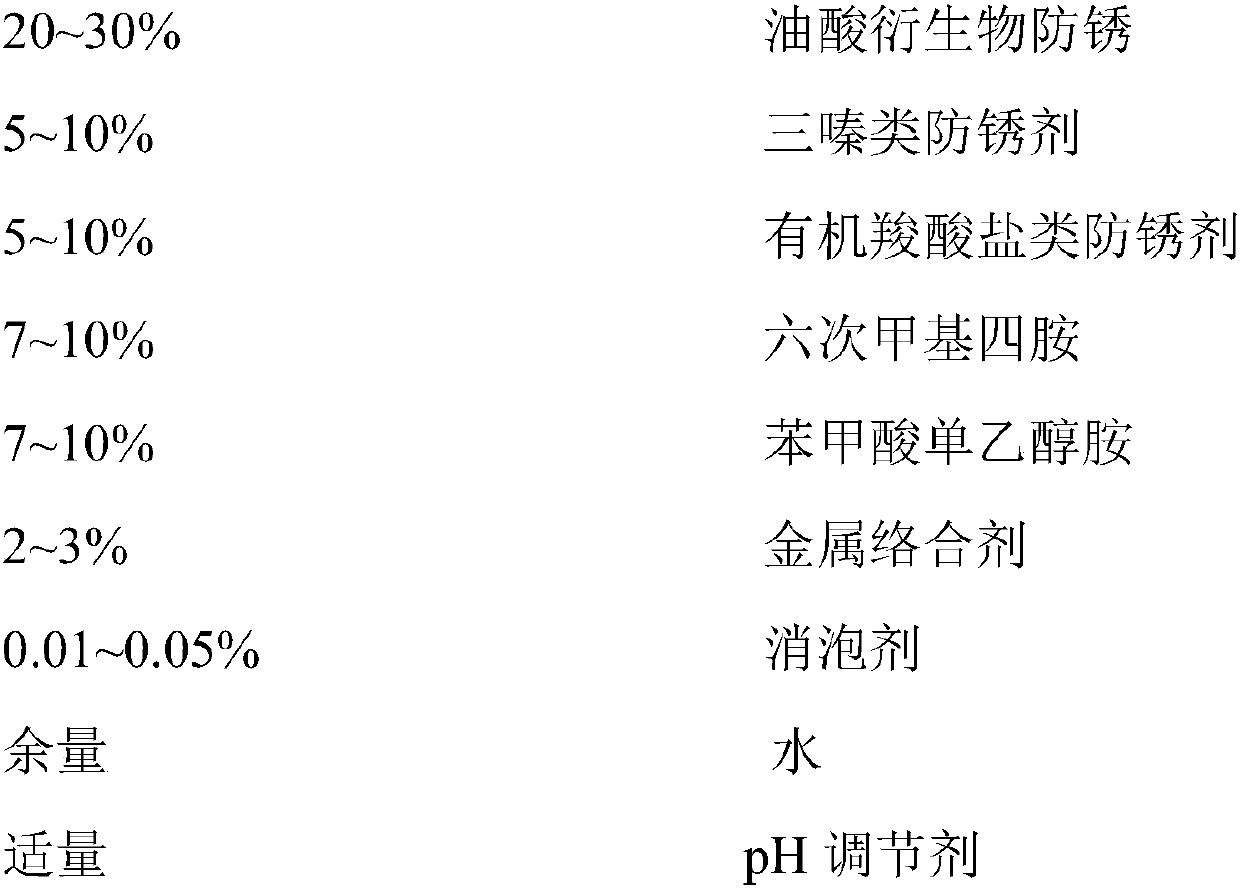

Environment-friendly water-based gas-phase long-acting antirust solution composition, preparation method and use method

ActiveCN108034949APromote wettingImprove the lubrication effectLubricant compositionWater basedAdditive ingredient

The invention discloses an environment-friendly water-based gas-phase long-acting antirust solution composition which comprises the following raw materials: an oleic acid derivative antirust agent, atriazine antirust agent, an organic carboxylate antirust agent, hexamethylenetetramine, a benzotriazole corrosion inhibitor, monoethaneamine benzoate, a metal complexing agent, a defoaming agent, water and a pH (potential of hydrogen) regulator. The environment-friendly water-based gas-phase long-acting antirust solution composition takes water as a carrier, contains an oleic acid derivative antirust agent composite, is free from nitrite and other ingredients which are poisonous and harmful to a human body and an environment, is safe and environment-friendly, has excellent contact antirust capability, gas-phase antirust capability, lubricating capability, wetting ability and chemical adsorption capability, does not influence surface quality and precision of a steel ball (particularly, higher than level G10), facilitates cleaning and water treatment, reduces cost, and meets long-term antirust requirements and interprocess short-term antirust requirements of storage and package of the steel ball made from a steel based material such as carbon steel and stainless steel.

Owner:辽宁宝瑞科技有限公司 +1

Towel fabric vat dye wet shortened-steaming process

InactiveCN104631014AEase of environmental protectionGet good resultsSucessive textile treatmentsHeating/cooling textile fabricsPulp and paper industryDyeing

The invention relates to a tower fabric vat dye wet shortened-steaming process. The tower fabric vat dye wet shortened-steaming process specially includes a conventional vat dye suspensoid pad dyeing process and a vat dye wet shortened-steaming pad dyeing process. The conventional vat dye suspensoid pad dyeing process includes the steps of dye liquor preparation, padding of a semi-finished product in vat dye suspensoid dye liquor, infrared pre-drying, hot air pre-drying, drying cylinder drying and cropping (cooling). The vat dye wet shortened-steaming pad dyeing process includes the steps of dry liquor preparation, padding of the semi-finished product in the vat dye suspensoid dye liquor, padding of a liquor sealing opening in reduction liquid, steaming, cold running water washing (2-3 cells) and 1 cell oxidation, ventilation, 1 cell hot washing, 1 cell soaping, 1 cell soap boiling, 2 cell hot washing, drying and cropping (cooling). By the adoption of the technology, the effect can be well acquired, energy is saved, environment friendliness is achieved, and use is convenient.

Owner:QINGDAO XINYIFA IND & TRADE

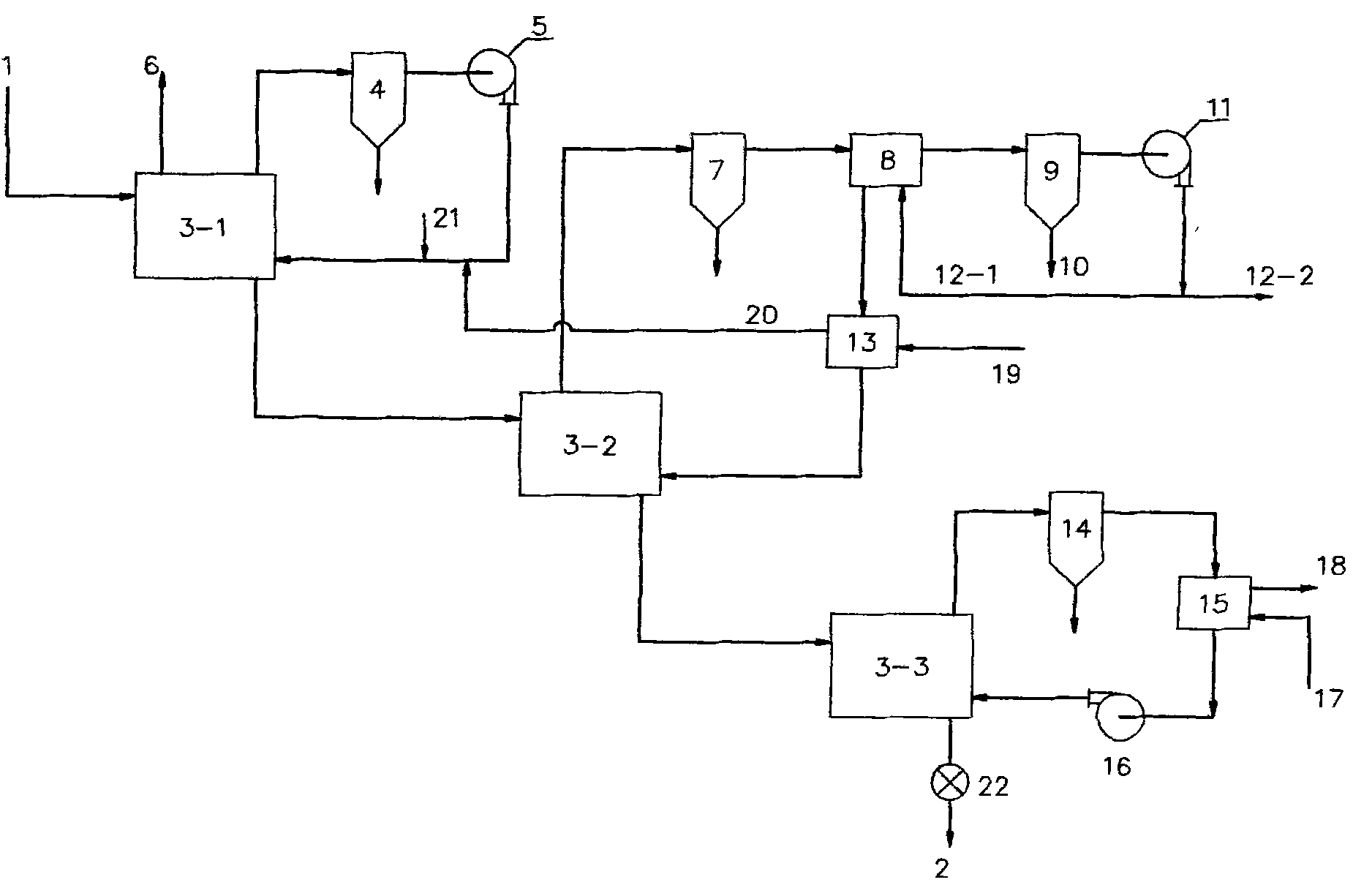

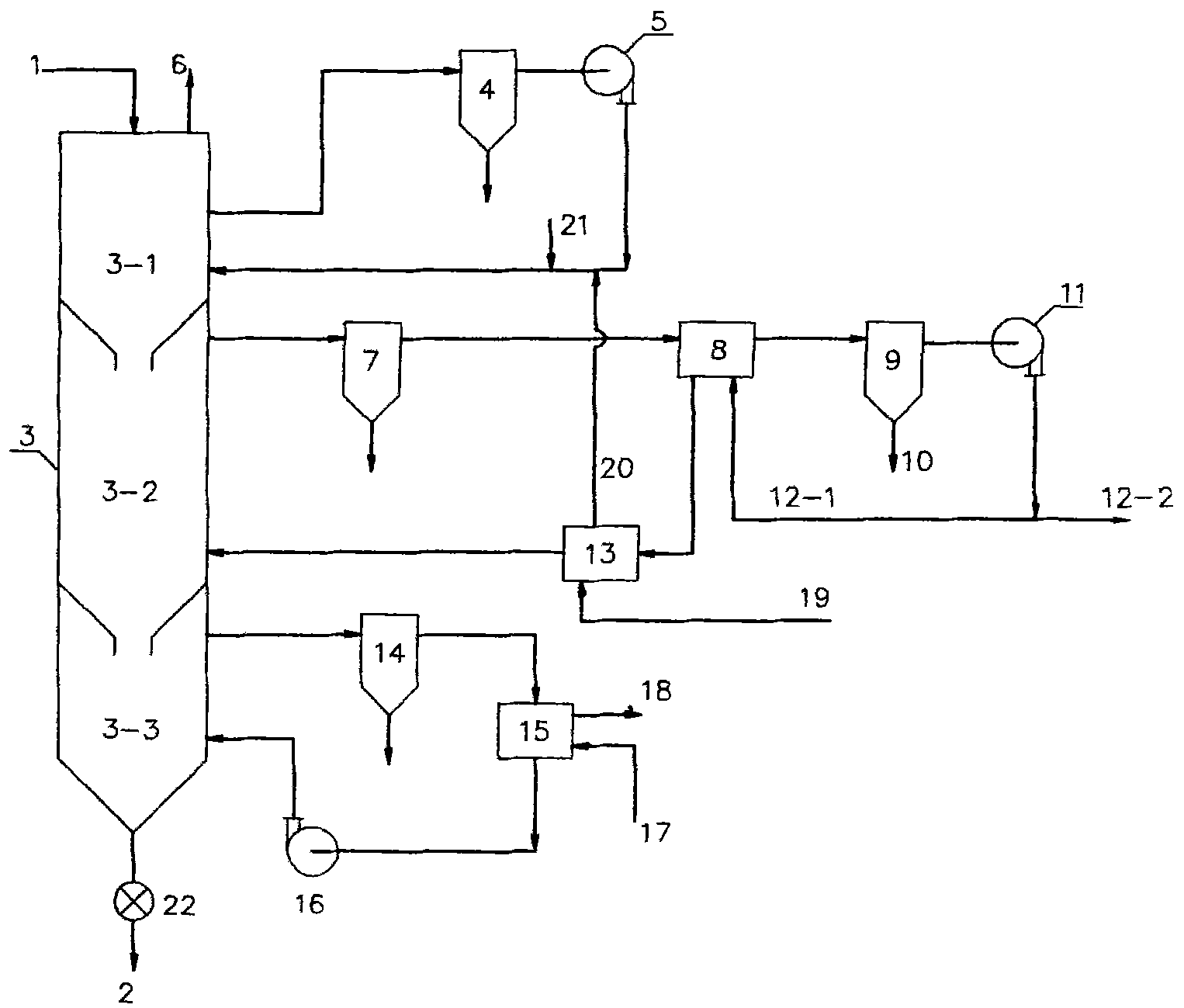

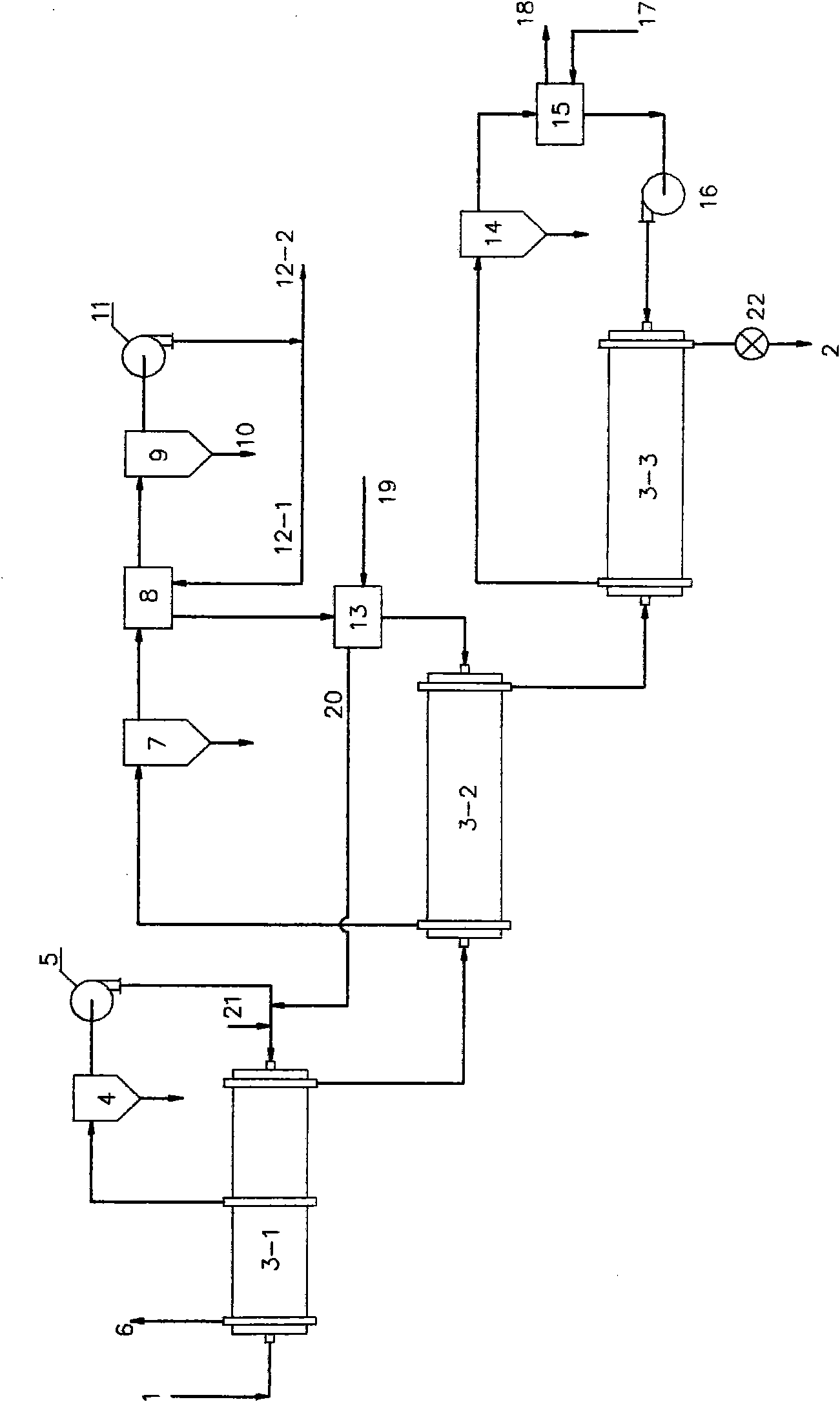

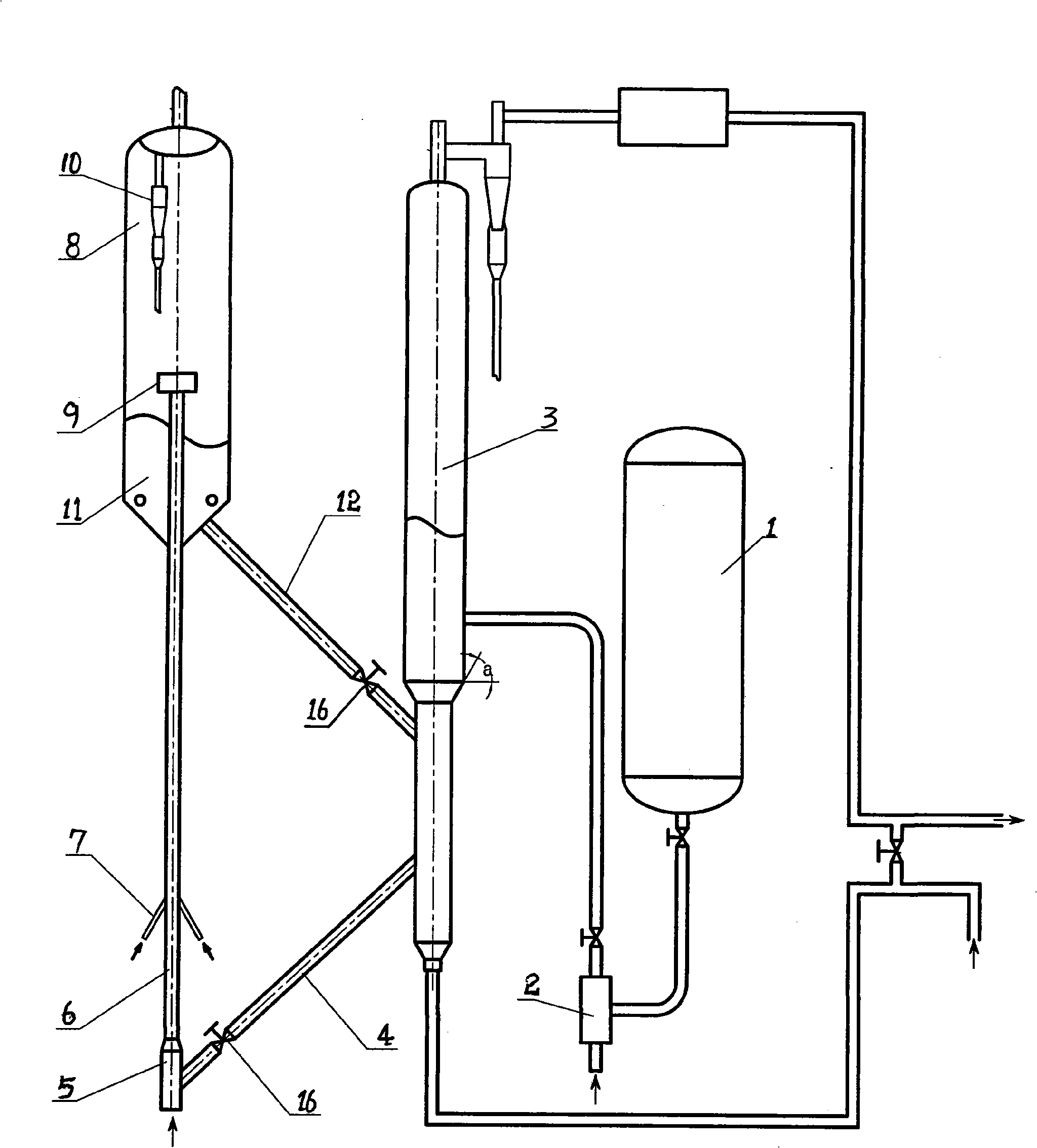

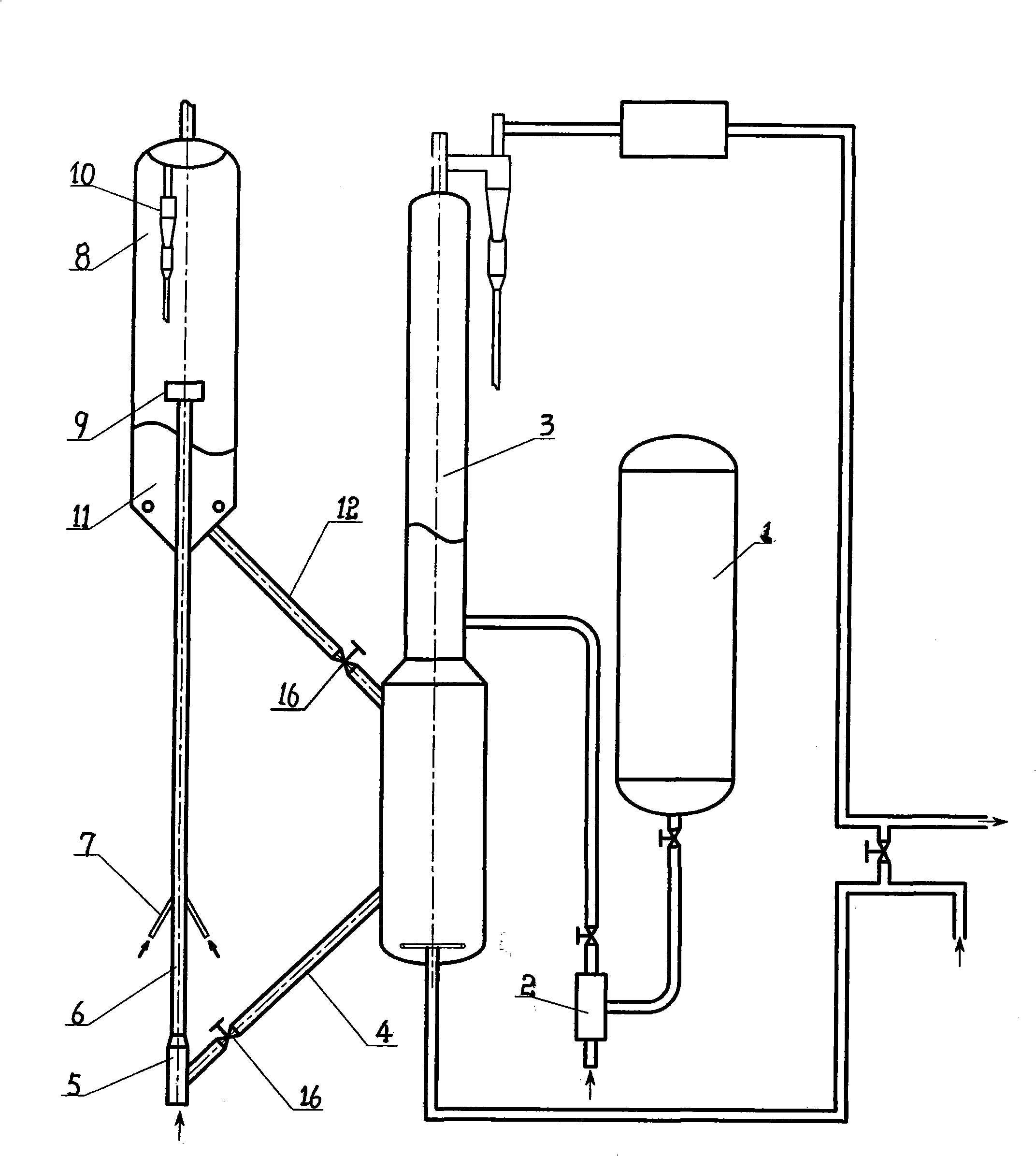

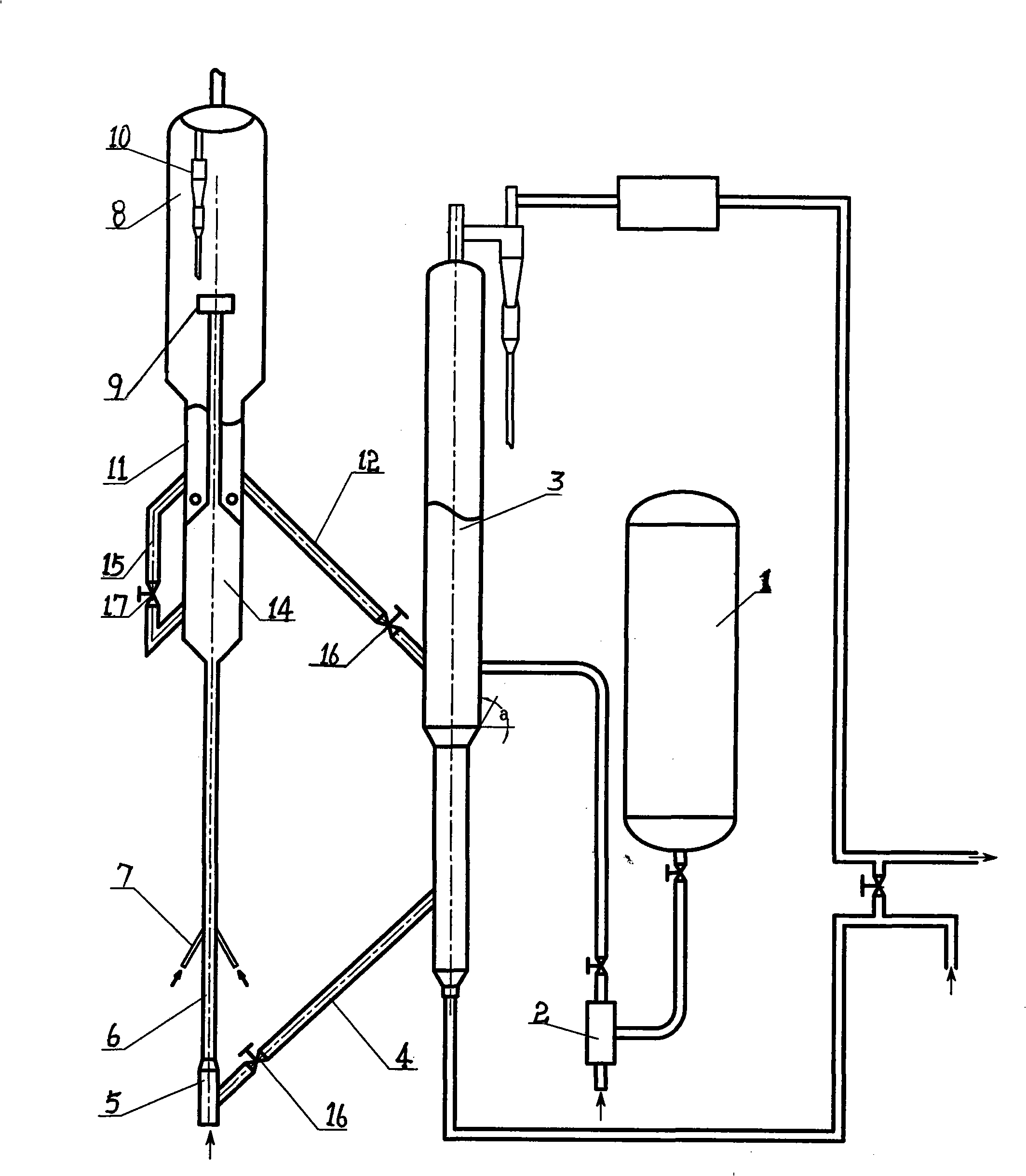

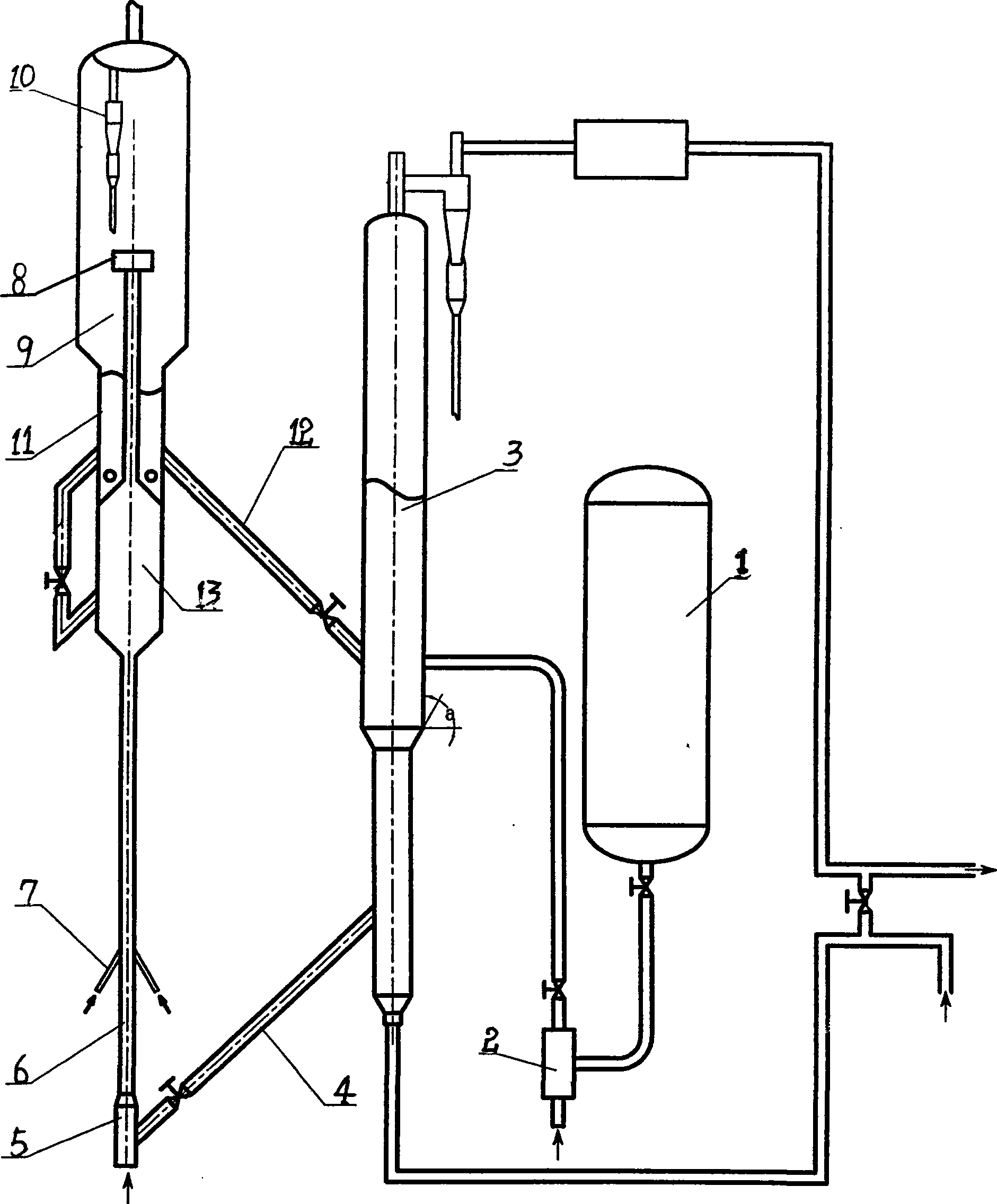

Equipment for preparing carbon disulfide with circulating fluidized bed

The invention relates to an apparatus for producing a compound containing carbon and sulfur, in particular to an apparatus for preparing carbon bisulfide with a circulating fluidized bed. The apparatus solves the disadvantages of the existing carbon bisulfide production process and equipment and comprises a storage hopper, a feeder and a fluidized bed furnace, a hot carbon pipeline is arranged under the fluidized bed furnace, the other end of the hot carbon pipeline is communicated with a pre-raiser, the upper part of the pre-raiser is connected with a riser which is provided with a nozzle, the upper end of the riser extends into a settler, the end of the riser is provided with a quick separation device, the internal top part of the settler is provided with a cyclone separator, the internal lower part of the settler is provided with a stripping section, and the lower part of the stripping section is provided with a cold carbon pipeline. By adopting the pre-raiser, the riser and the fluidized bed coating, the apparatus of the invention improves the contact efficiency of reactants; the sulfur can be a liquid state, the temperature is lower, the apparatus is simple; the arrangement of the stripping section can reduce pollution, and improve product yield; the apparatus has the advantages of simple structure, low cost, easy production, and is beneficial to realizing the continuous and automatic production and environmental protection treatment in course of production.

Owner:孔庆然

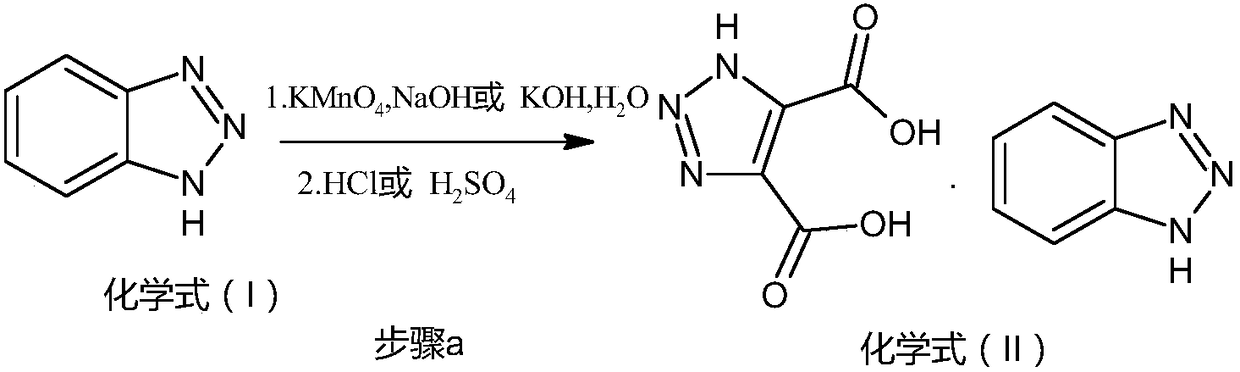

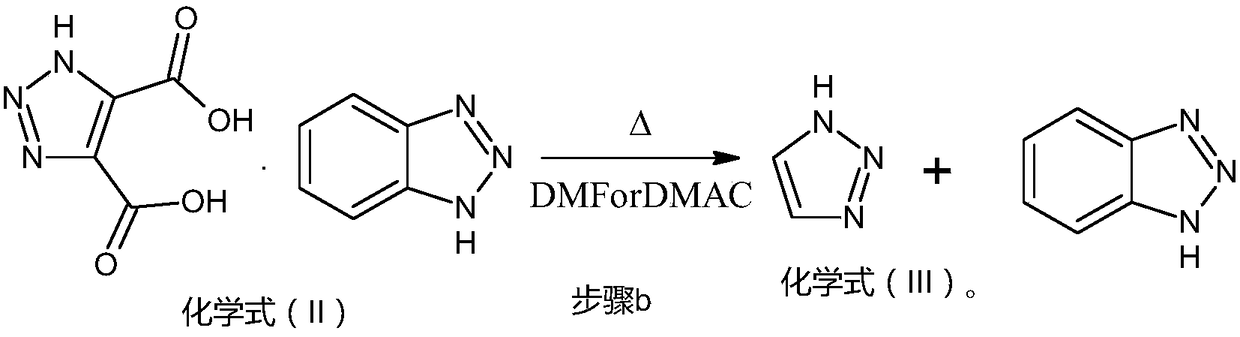

Preparation method of 1H-1,2,3-triazole

The invention discloses a preparation method of 1H-1,2,3-triazole. According to the method, benzotriazole is taken as a raw material and subjected to oxidation and decarboxylation, then distillation purification is performed, and high-purity 1H-1,2,3-triazole is obtained. Raw materials of the whole synthesis route are cheap and easily available, operation is simple and convenient, operation cost is low, the process is environmentally friendly, and the method is quite suitable for industrial production and has quite high industrial application value.

Owner:SHANGHAI JINJING CHEM CO LTD

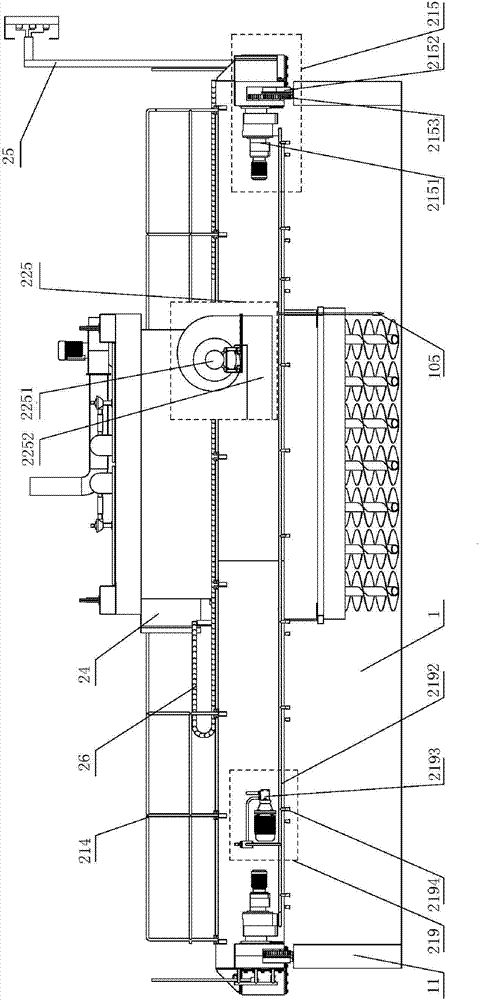

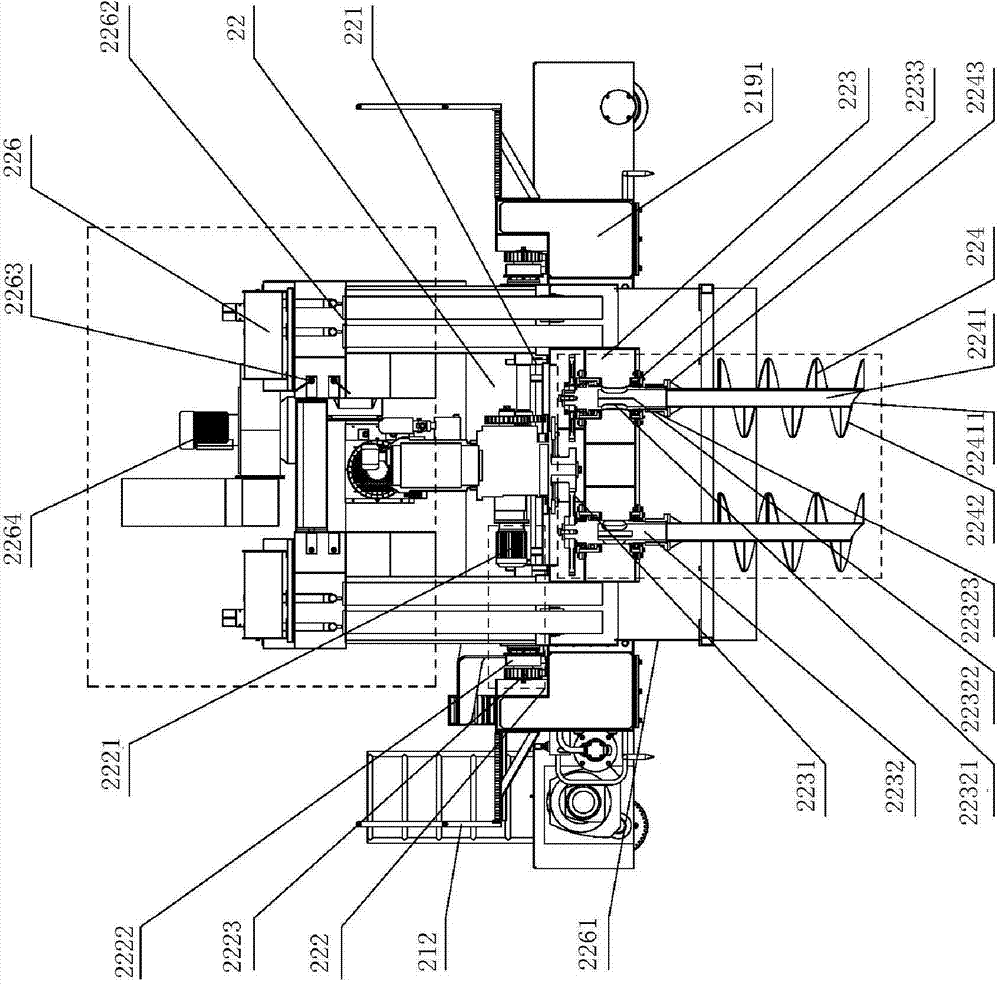

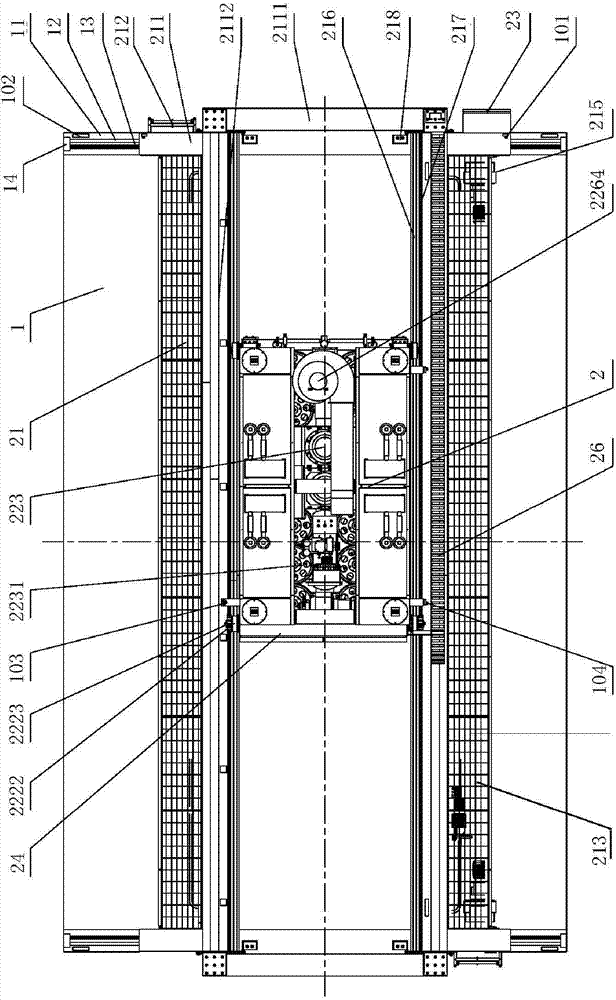

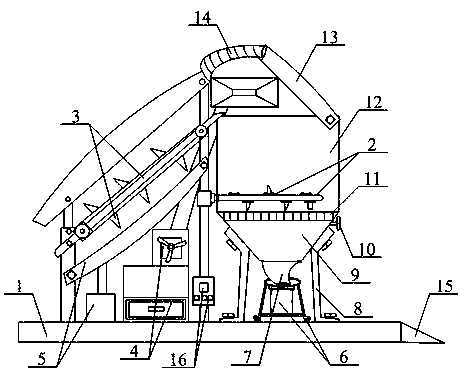

Trestle-type floatation helical fermentation system and operating control method thereof

ActiveCN104725089ALow investment costTo achieve harmonious developmentBio-organic fraction processingClimate change adaptationDrive shaftAgricultural engineering

The invention relates to a trestle-type floatation helical fermentation system and an operating control method thereof. The trestle-type floatation helical fermentation system comprises a fermentation tank and a trestle-type floatation helical fermentation turner which is installed on the fermentation tank and can make a reciprocating movement along the fermentation tank, wherein the trestle-type floatation helical fermentation turner comprises a mobile trestle and a helical turning vehicle which is installed on a trestle cross beam of the mobile trestle and can make a reciprocating movement along the mobile trestle; the width of the fermentation tank 10-45m, and the length is 50-500m; the helical turning vehicle is provided with a turning transmission gear, a ventilation aeration device and a hollow helical turning shaft; the ventilation aeration device is provided with a ventilating duct composed of a closed inner cavity of the helical turning vehicle machine frame; the turning transmission gear is provided with a hollow transmission shaft with a closed upper end and an open lower end; the hollow transmission shaft penetrates through the ventilating duct, and the axial wall in the ventilating duct is provided with ventilating holes communicated the ventilating duct; and the hollow helical stirring shaft is connected to the lower end of the hollow transmission shaft.

Owner:GUANGXI LIYUANBAO SCI & TECH

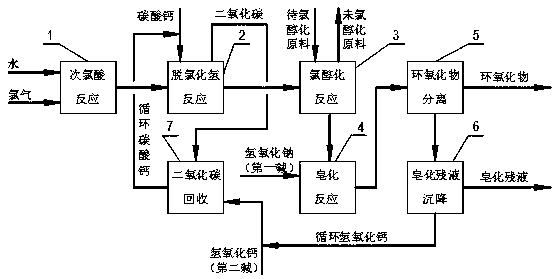

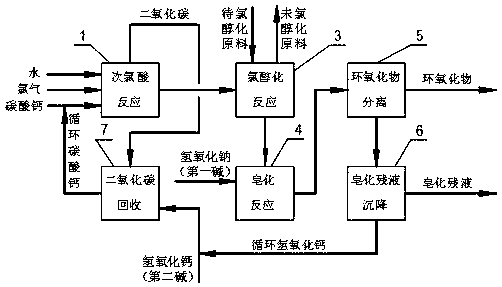

Production method of epoxide through dual-alkali chlorohydrination method

InactiveCN108440453AReduce generationReasonable useProductsOrganic chemistryHigh concentrationResource utilization

The invention provides a production method of epoxide through a dual-alkali chlorohydrination method. According to the preparation method, hydrogen chloride produced in a process of dehydrating calcium carbonate and reacting with chlorine gas to generate hypochlorous acid; high-concentration hypochlorous acid without the hydrogen chloride is used for carrying out chlorohydrination reaction; then sodium hydroxide is used for carrying out saponification reaction, and carbon dioxide produced in a process of removing the hydrogen chloride is recycled by utilizing calcium hydroxide slurry. According to the method provided by the invention, a few of byproducts are generated in a chlorohydrination process and raw materials to be subjected to chlorohydrination are transformed into more target products; in a saponification process, no waste dreg is generated and a saponification tower is not blocked; less residual water is generated in a saponification reaction process; the saponification residual water has a simple composition, and environment-friendly treatment and resource utilization are easy to realize; materials without the hydrogen chloride have light corrosion on equipment; calciumhydroxide and the calcium carbonate, which are generated in a system, can be cyclically utilized; the epoxide produced by the method provided by the invention has remarkable economic benefits and environmental benefits.

Owner:吴剑华

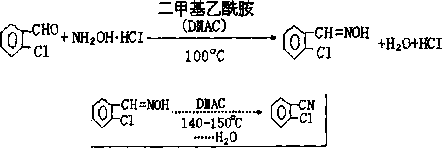

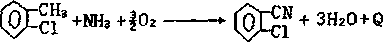

Synthetic method for 2-chlorobenzonitrile

ActiveCN110423207ARealize cleaner productionAvoid complex processOrganic compound preparationCarboxylic acid amides preparationChlorobenzoates2-chlorobenzamide

A synthetic method for 2-chlorobenzonitrile is disclosed and includes the following steps: performing a reaction on o-chlorobenzoic acid and ammonia to generate ammonium o-chlorobenzoate, high temperature dehydration is performed to produce 2-chlorobenzamide, and the high temperature dehydration is performed again to generate the 2-chlorobenzonitrile. In a production process, especially ultrasonicor microwave catalyzed high temperature dehydration is utilized to produce the 2-chlorobenzonitrile, the yield is up to 93%, and the purity of products can reach 97%. And the method has the characteristics of short process route, high reaction yield, good product purity, safe and clean whole reaction process, and easy environmentally friendly treatment. Production of waste water of the 2-chlorobenzonitrile can be effectively reduced, clean production of the 2-chlorobenzonitrile is achieved, unreacted raw material o-chlorobenzoic acid and intermediates can be recovered and then recycled and utilized, and the production cost can be significantly reduced. Moreover, the method can avoid the defects that traditional process equipment is complex, is high in operation requirements and is low inproduct yield, has the characteristics of less "three wastes" and less pollution, is another ideal way to achieve industrial production, and has strong market competitiveness.

Owner:三门峡环宇生化科技有限公司

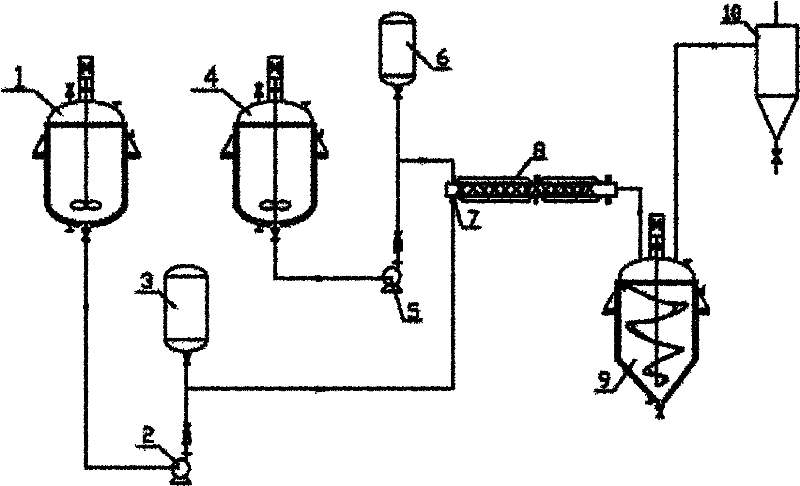

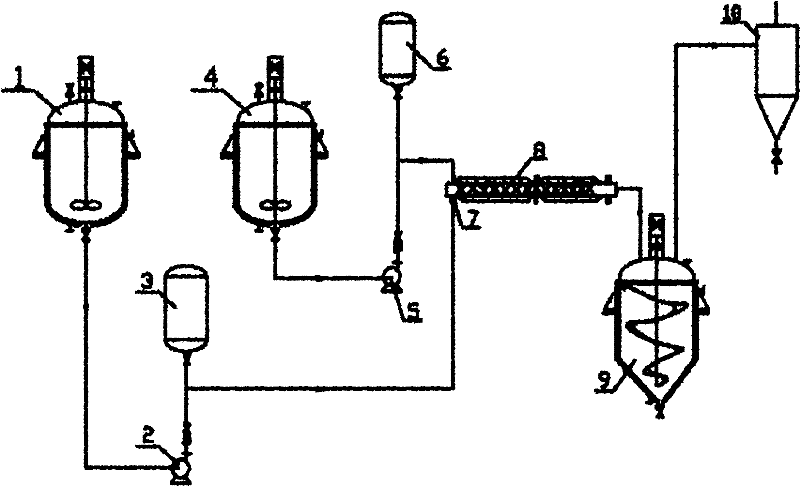

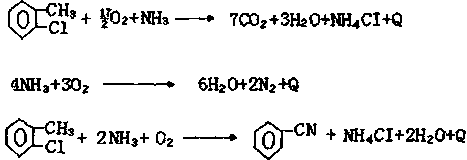

Environment-friendly high-efficiency modified asphalt waterproof roll mixing device and process

ActiveCN105647210AAvoid formingWell mixedBuilding insulationsBituminous waterproofingFilling materials

The invention discloses an environment-friendly high-efficiency modified asphalt waterproof roll mixing device and process. The device comprises an asphalt preheating kettle, a tire powder mixing kettle, a filling material mixing kettle, an SBS modifier mixing kettle and a modified asphalt mixing kettle which are connected with one another through a pipeline, a heating device and a stirring device are arranged inside each of the asphalt preheating kettle, the tire powder mixing kettle, the filling material mixing kettle, the SBS modifier mixing kettle and the modified asphalt mixing kettle, the tire powder mixing kettle, the filling material mixing kettle and the SBS modifier mixing kettle are parallelly connected through a mixing pipe, a discharging port of the asphalt preheating kettle is connected with feeding ports of the tire powder mixing kettle, the filling material mixing kettle and the SBS modifier mixing kettle respectively, and discharging ports of the tire powder mixing kettle, the filling material mixing kettle and the SBS modifier mixing kettle are connected with a feeding port of the modified asphalt mixing kettle respectively. By using the device, various materials are separately stirred and mixed, and powder and oil are avoided forming a mixture; each material is dispersed more uniformly, so that stirring time is shortened effectively.

Owner:KUNSHAN KESHUN WATERPROOF MATERIAL

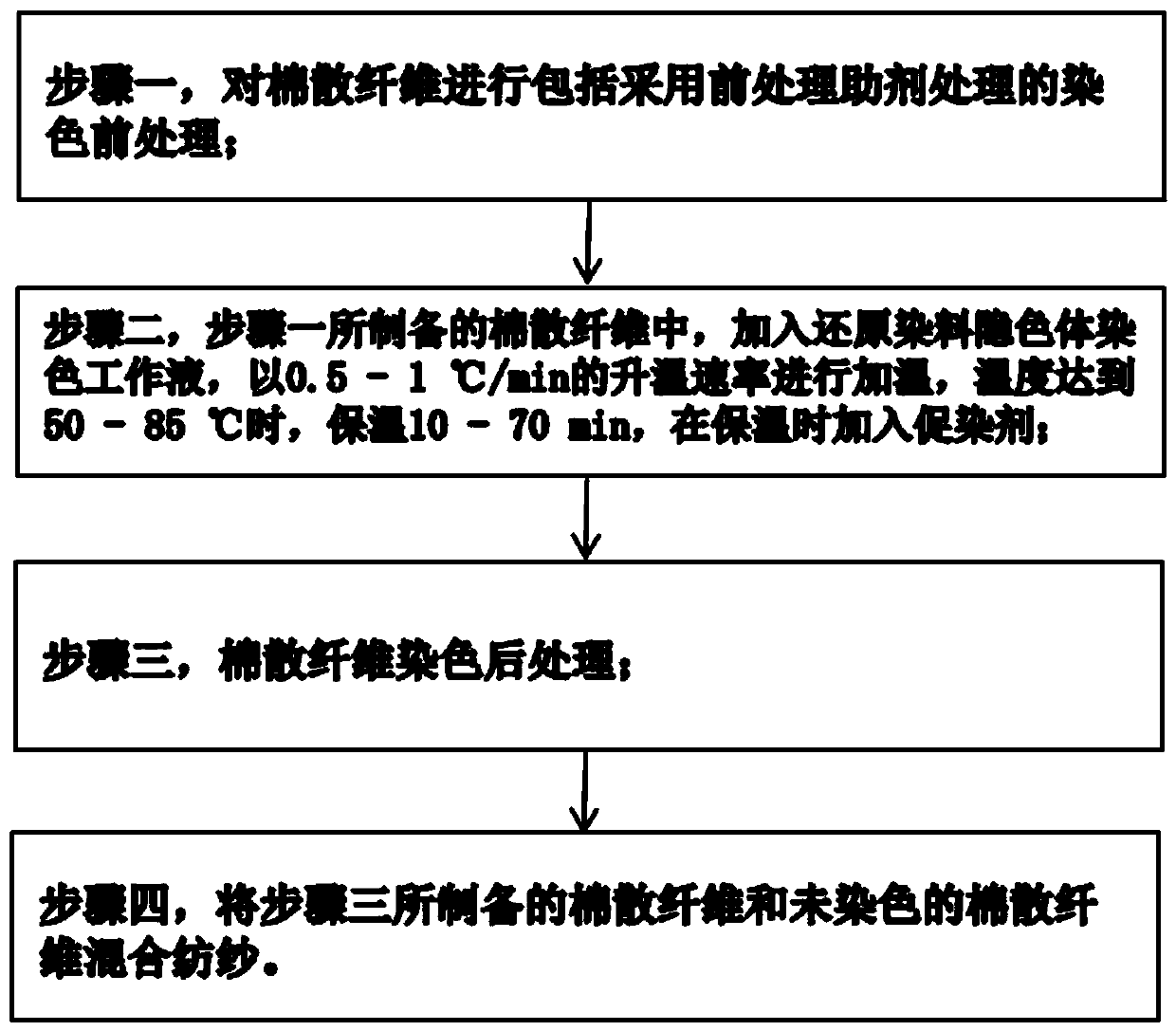

Manufacturing method of colorized denim yarn and fabric and garment manufactured through yarn

InactiveCN111455518AHigh color fastnessNot easy to fadeDry-cleaning apparatus for textilesDyeing processYarnFiber

The invention provides a manufacturing method of colorized denim yarn. The manufacturing method comprises the following steps that firstly, cotton loose fibers are subjected to deying pretreatment including treatment adopting pretreatment auxiliaries; secondly, vat dye leuco body dyeing work fluid is added into the cotton loose fibers prepared in the first step, heating is carried out at the temperature increase rate of 0.5-1 DEG C / min, when the temperature reaches 50-85 DEG C, heat preservation is carried out for 10-70 min, and an accelerant is added during heat preservation; thirdly, dyeingaftertreatment of the cotton loose fibers is carried out; and fourthly, the cotton loose fibers prepared in the third step and non-dyed cotton loose fibers are mixed for spinning. Fabric formed by weaving the yarn manufactured through the method is good in dyefastness and is not prone to fading during washing.

Owner:苏州中纺学面料产业研究院

Process for preparing carbon disulphide by using circulating fluid bed

The invention relates to a production method for a compound comprising carbon and sulfur, in particular to the technology for preparing carbon bisulfide by a circulating fluid bed, which aims at solving the problems of high energy consumption, discontinuous production process, serious environment pollution and the like in the existing production technology. The method comprises the following steps: carbonic solid substances are sent to a fluidized bed furnace, the heated carbonic solid substances are then sent to a pre-raiser, a lift pipe and a fluidized bed layer and contact and react with sulfur, a quick separation device and a settler are used for separating the gaseous carbon bisulfide out, and the rest unreacted carbonic solid substances fall in a stripping section under the settler, and return to the fluidized bed furnace to be heated after the entrained carbon bisulfide gas is stripped by inert gases. The method has the advantages of greatly improving the contact efficiency of the reactant, requiring lower temperature owing to liquid sulfur, having simple device, simple structure and low construction cost, reducing pollution and improving product yield thanks to the arrangement of the stripping section, which is beneficial to the realization of continuous and automatic production and the environmental protection treatment in the production process.

Owner:孔庆然

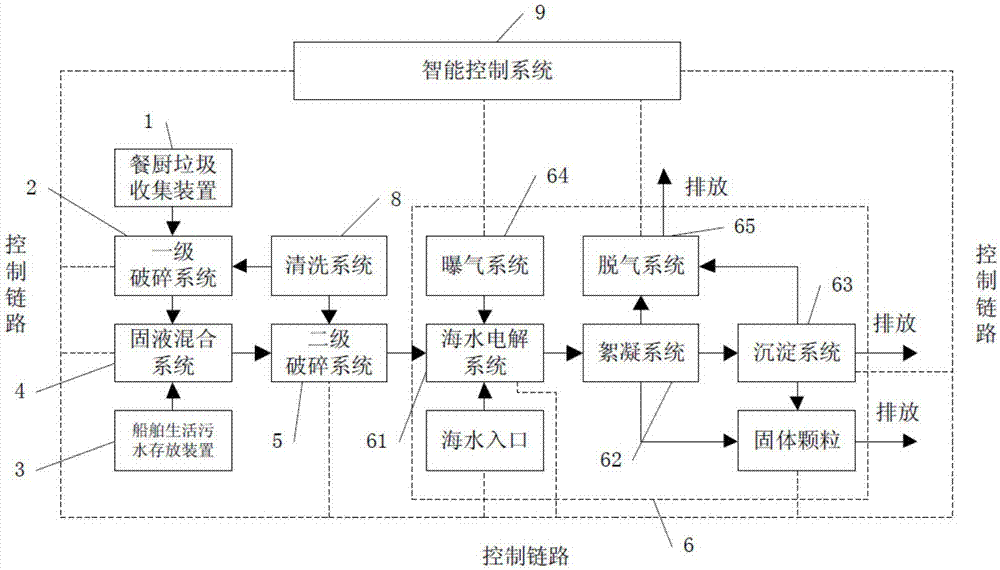

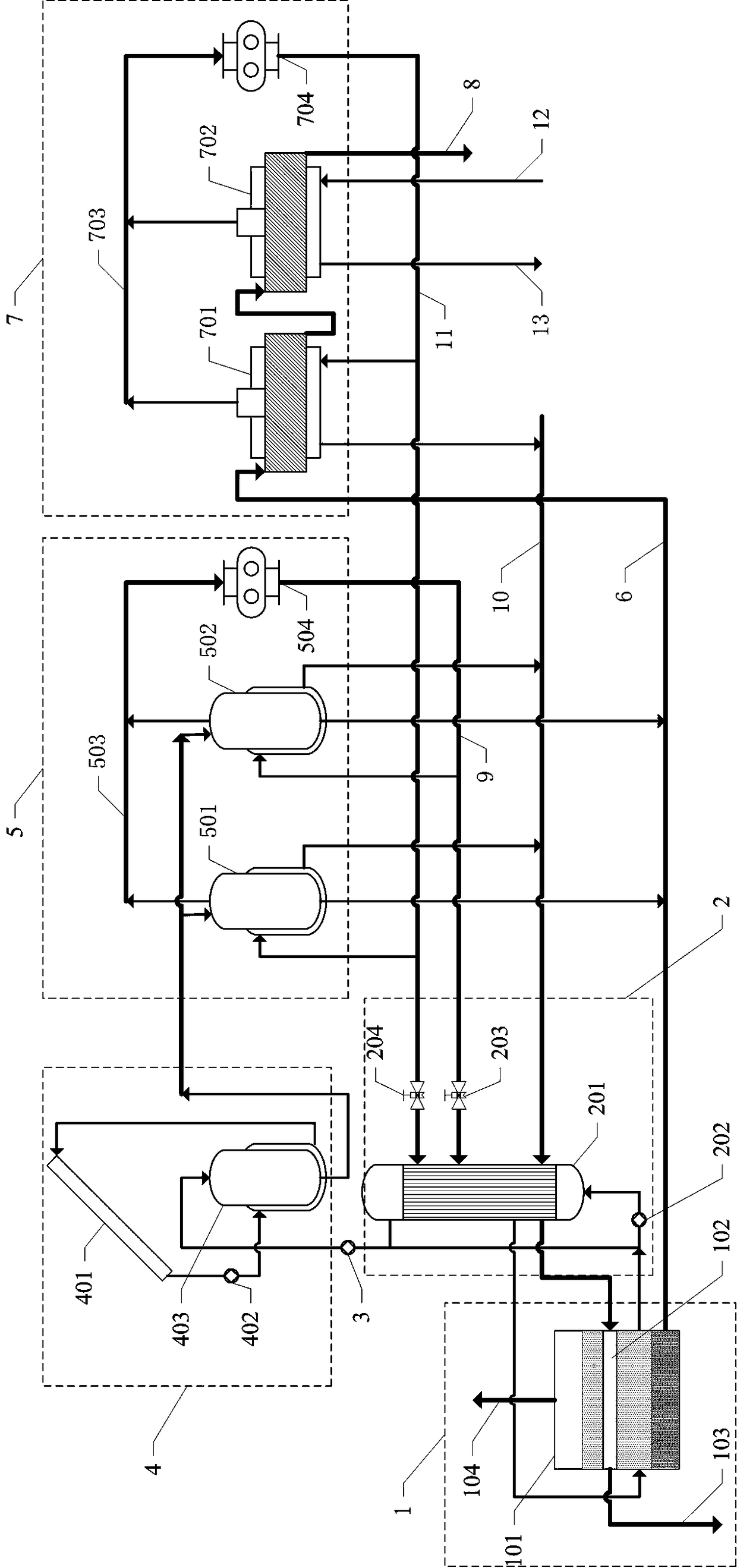

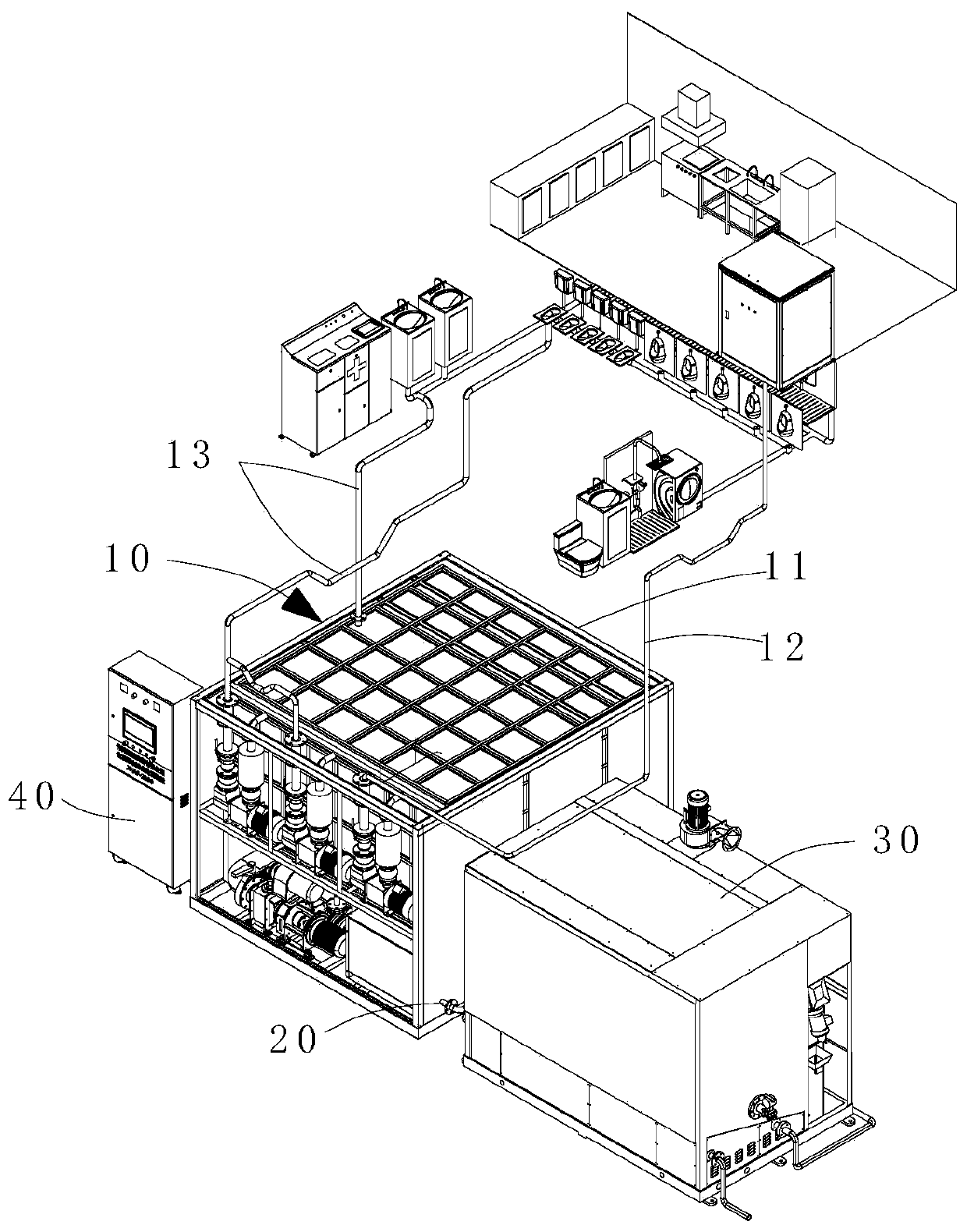

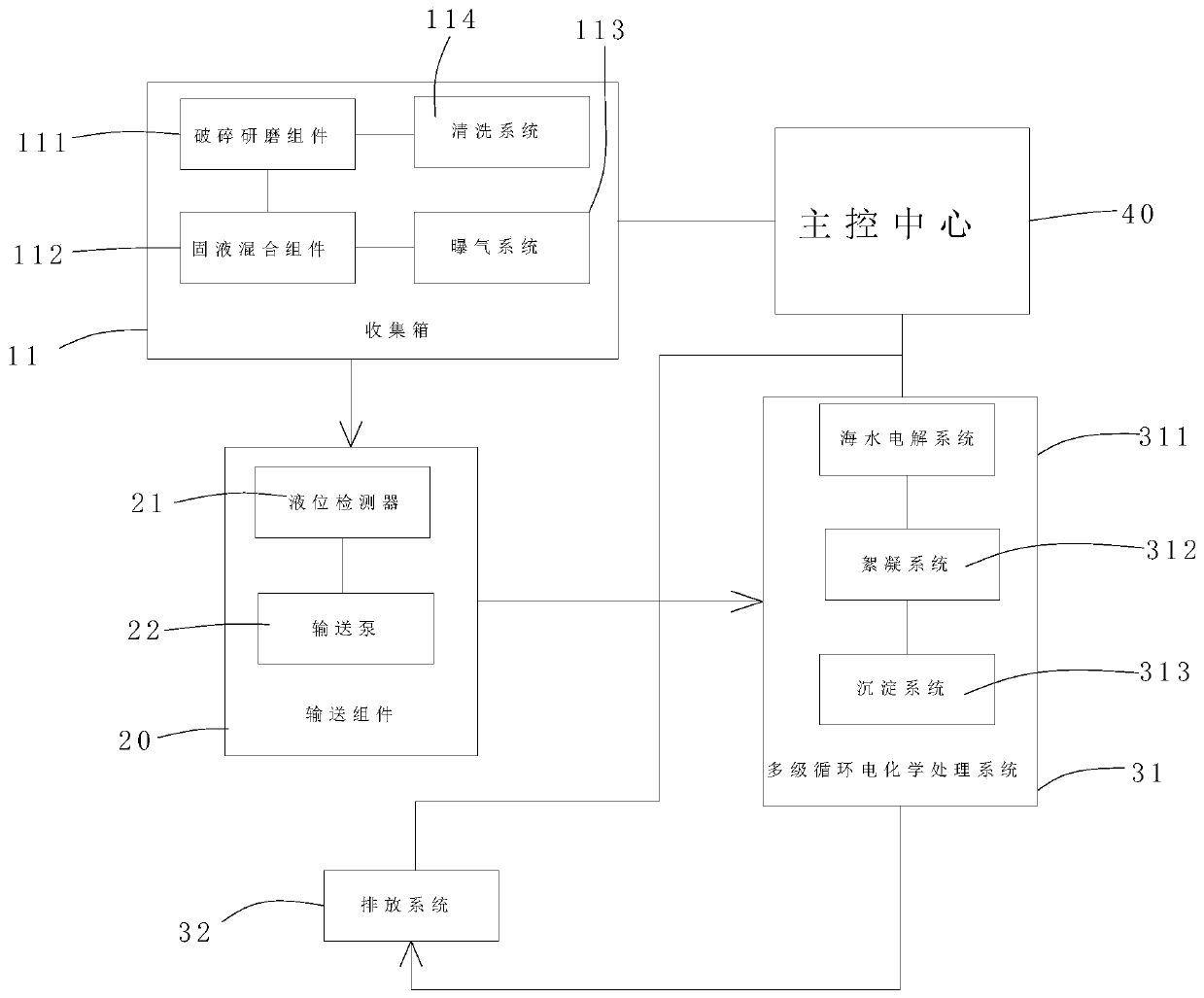

Comprehensive treatment system and method of domestic sewage and food wastes for naval ships

InactiveCN106890838AEase of environmental protectionSeawater treatmentSolid waste disposalChemical treatmentRefuse collection

The invention discloses a comprehensive treatment system and method of domestic sewage and food wastes for naval ships. The comprehensive treatment system comprises a food wastes collection device, a primary crushing system, a ship domestic sewage storage device, a solid liquid mixing system, a secondary crushing system, a circulating electrochemical treatment system and a sludge and sewage discharge device. According to the comprehensive treatment system and method of the domestic sewage and the food wastes for the naval ships, the work efficiency of the ship sewage treatment system is improved, the volume and the capacity of the ship sewage treatment system is reduced, and the manufacturing cost is reduced. In addition, the method based on comprehensive treatment system of domestic sewage and food wastes for naval ships has the characteristics of a simple system structure, safe and reliability, and high processing efficiency.

Owner:GUANGZHOU WEI YE MARINE EQUIP CO LTD

Membrane filtration process method of meleumycin

InactiveCN104109181AQuality improvementHigh light transmittanceSugar derivativesSugar derivatives preparationEmulsionAntibiotic Y

The invention discloses a membrane filtration process method of meleumycin, and belongs to a method for extracting and producing antibiotics by solid-liquid separation of a fermentation broth. A flat ultrafiltration membrane, a roll type ultrafiltration membrane or a tubular ultrafiltration membrane is used to filter the fermentation broth to carry out the solid-liquid separation, to obtain a filter solution with relatively high transmittance; the filter solution is subjected to extraction and phase inversion; finally a phase inversed solution is crystallized and then separated by a centrifugal machine; and a crystal is dried to obtain a meleumycin finished product. By using the membrane filtration to replace a conventional plate-frame pressure filtration process, the process method has the following advantages and positive effects of fast filtration speed, good filtration quality, high transmittance, and significantly increased pressure filtration yield, eradicates extraction and emulsion phenomenon, and has high yield of finished product and good quality finished product. Besides, the membrane filtration technology is not complex in investment and reconstruction, is few in additional devices, and is suitable for industrial production.

Owner:CHONGQING DAXIN PHARMA +2

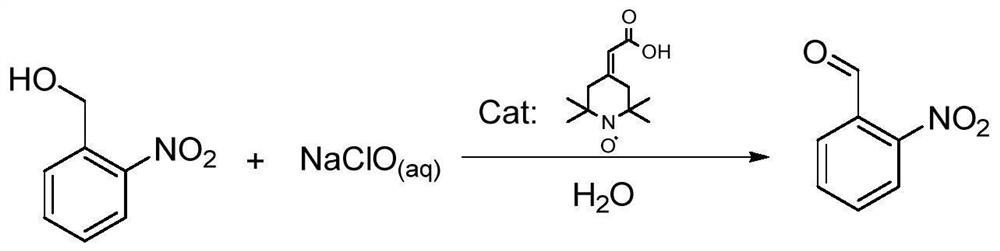

Preparation method of o-nitrobenzaldehyde

ActiveCN113087628AMild and moderate oxidationShort preparation timeOrganic chemistryOrganic compound preparationPtru catalystNitrobenzene

The invention discloses a preparation method of o-nitrobenzaldehyde, wherein the preparation method comprises the following steps: (1) adding o-nitrobenzyl alcohol, a catalyst, a bromide salt and a solvent into a reaction kettle, and uniformly stirring at room temperature; (2) controlling the reaction temperature, slowly dropwise adding a sodium hypochlorite solution into the reaction kettle, and simultaneously adding a weakly alkaline substance or an acidic substance to control the pH value of the reaction; (3) standing for layering, adding an organic solvent to extract a product, and concentrating to obtain a crude product; and (4) crystallizing by using an organic solvent, centrifuging, and drying in vacuum to obtain o-nitrobenzaldehyde. According to the method, 2-(2,2,6,6-tetramethylpiperidine nitroxide radical-4-subunit) acetic acid which is low in price and easy to obtain is used as a catalyst, the sodium hypochlorite solution is used as an oxidizing agent, a mixed solvent of water and chlorinated hydrocarbon is used as a reaction solvent, the o-nitrobenzaldehyde is prepared through oxidation under the mild temperature condition, the raw materials are low in price and easy to obtain, the reaction time is short, the reaction selectivity is high, and the yield is high.

Owner:陕西西岳制药(扶风)有限公司 +1

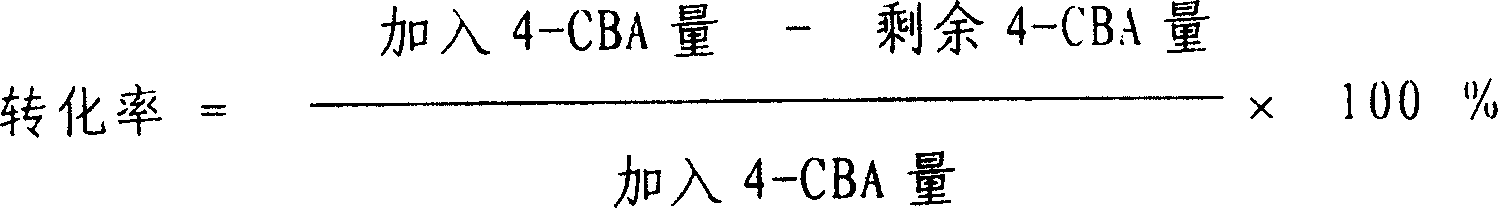

Supported palladium/carbon catalyst for hydrogen refining and method for preparing the same

InactiveCN101492611ALower redox potentialEvenly distributedRefining to eliminate hetero atomsDispersityHydrogen

The invention relates to a load type palladium / carbon catalyst used for hydrogen refining and a preparation method, mainly solving the problems in the prior art that Pd dispersity of Pd / c catalyst is low, microcrystal content is low, thermal stability is weak, and conversion rate of p-carboxyl benzaldehyde raw material is low . In the invention, palladium loaded on carrier active carbon is in microcrystal form, wherein the microcrystal less than 2.5 nanometer accounts for 90wt% of the total weight of the microcrystal palladium, and solution used for dipping or spraying the active carbon carrier contains Pd compound. In a COOH(CH2)nCOOH additive and a BCH3(CH2)m(CH3)3NBr additive, n is an integer ranging from 0 to 3 and m is an integer ranging from 8 to 20, wherein, the technical proposal that m is an integer ranging from 8 to 20 well solves the problems. The invention can be applied to the industrial production of terephthalic acid hydrobon catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

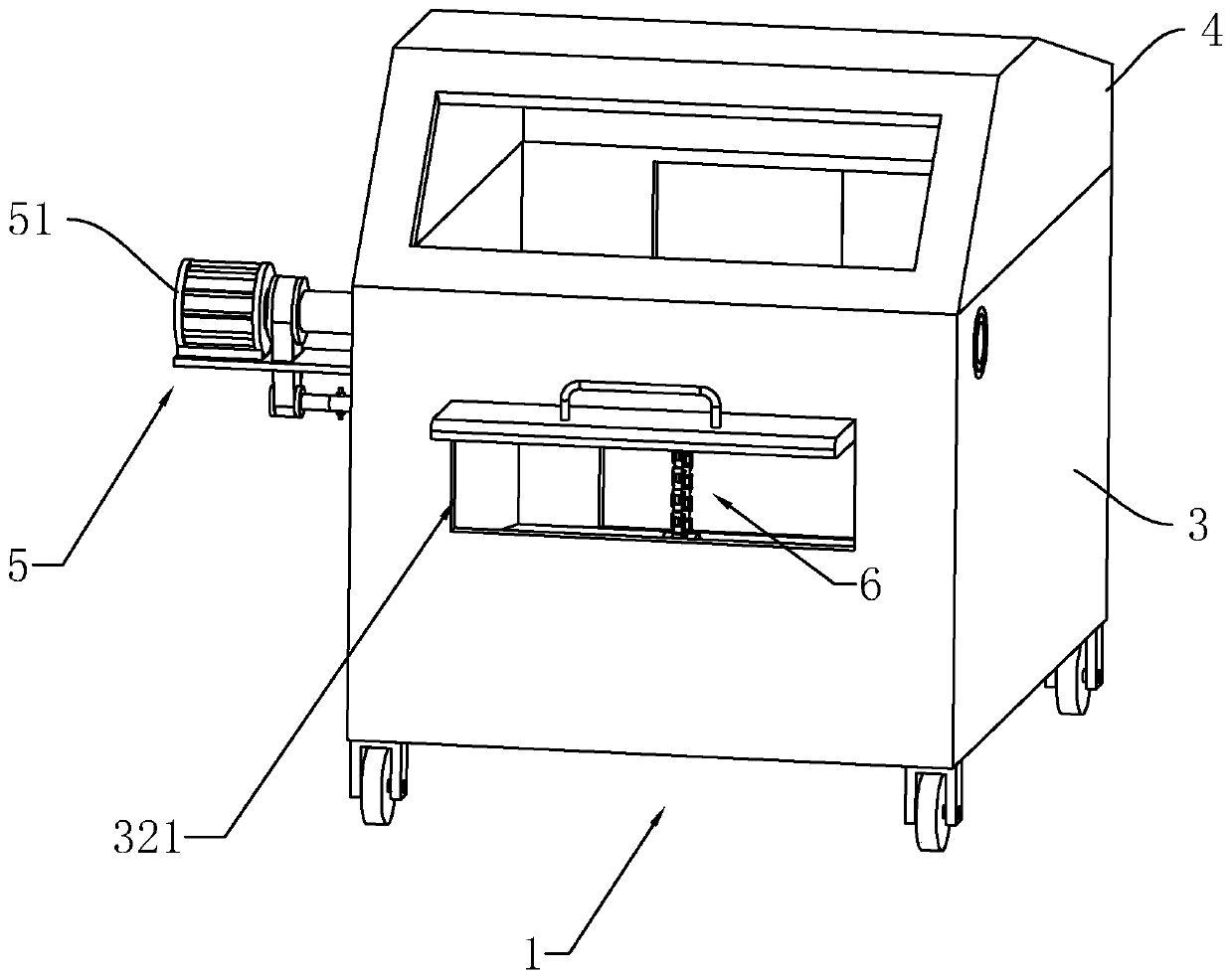

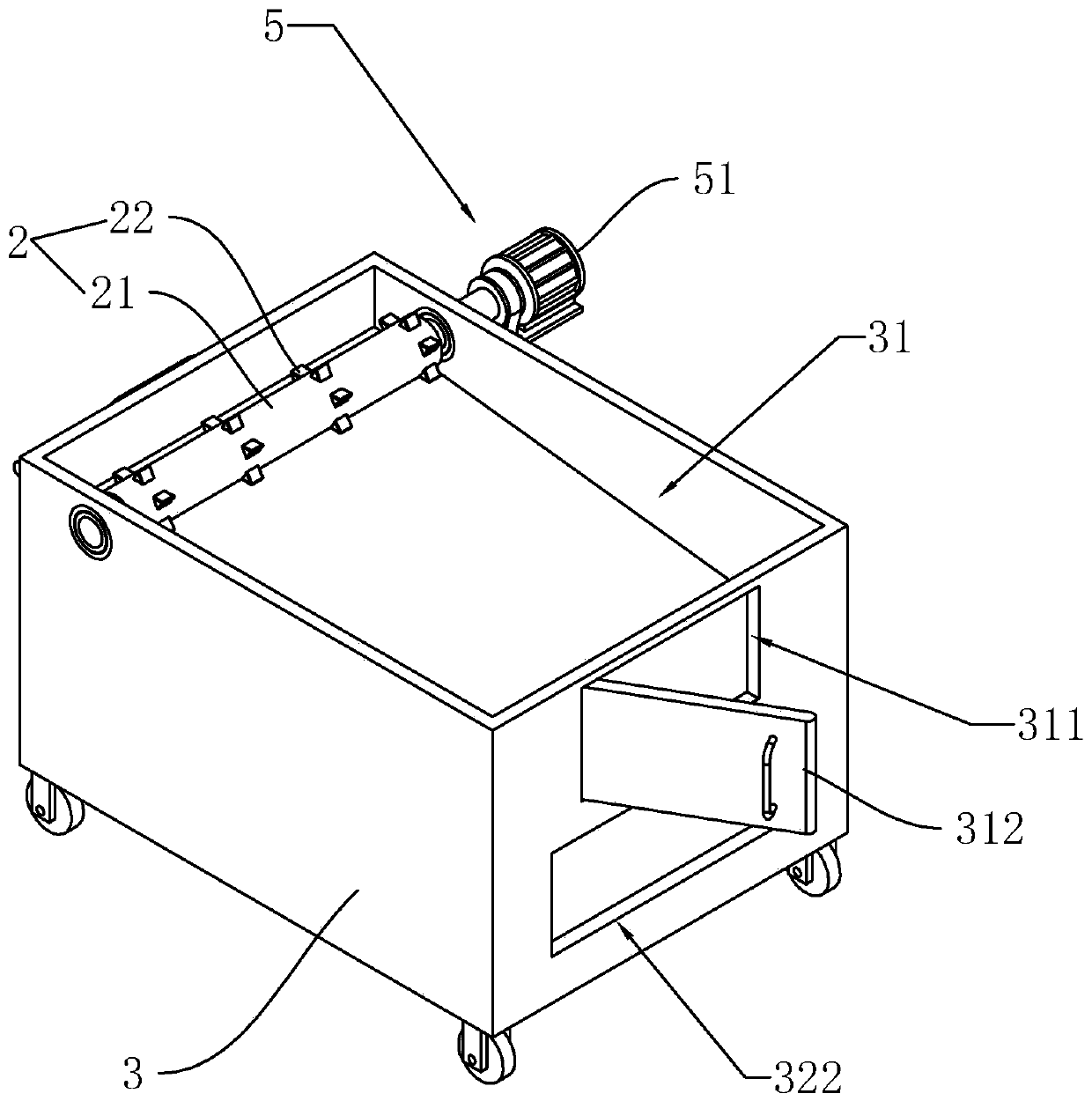

Agricultural wheat straw environmental protection treatment device

ActiveCN108811797AStir wellEase of environmental protectionBalingCuttersTransmission beltEngineering

The invention provides an agricultural wheat straw environmental protection treatment device. The device comprises a fixed base, a wheat straw crushing and stirring shaft structure, a wheat straw continuous feeding transmission belt structure, an environment-friendly dust recovery cover structure, an adjustable leakage-proof recovery plate structure, a wheat straw feed containing frame structure capable of being used for weighing, a material guide distributing cylinder, support base frames, a funnel, a manual regulating valve, a filter screen plate, a wheat straw treatment box, an anti-dust box cover, a corrugated connection cover, a slope plate and a device control box. According to the invention, through the arrangement of a wheat straw stirring driving motor, a stirring shaft, crushingblades and a stirring rod, stirring and crushing on wheat straw are facilitated, the wheat straw is prepared into feed for easy storage and is used as the feed for livestock animals, and the environmental protection treatment of wheat straw is facilitated. Through the arrangement of a leaked material recovery plate, a recovery pipe and a wheat straw leakage storage box, the recovery and collectionof wheat straw materials which are leaked inadvertently during a conveying process are facilitated, and the utilization rate of the wheat straw is improved.

Owner:滨州旭展生物能源有限公司

Method for preparing basic copper chloride

ActiveCN107434256AAvoid tensionSimple processElectrolysis componentsCopper chloridesElectrolysisCopper chloride

The invention discloses a method for preparing basic copper chloride. The method comprises the following steps: 1, dividing an electrolytic tank into an anode area internally provided with an anode electrode and a cathode area internally provided with a cathode electrode by an ionic membrane, adding an aqueous sodium chloride solution as an anode electrolyte into the anode area, adding a water-containing cathode electrolyte into the cathode area, and carrying out an electrolytic reaction, wherein a water electrolysis reaction occurs on the anode electrode in the electrolytic tank; 2, reacting a product obtained in the anode area through the electrolytic reaction with copper and / or copper oxide; and 3, mixing an electrolytic product in the cathode area in step 1 with a reaction product in step 2 until the pH value is 3-7 in order to obtain a solid and liquid mixture, and carrying out solid-liquid separation on the solid and liquid mixture to obtain the basic copper chloride solid. The method has the advantages of simple process and low production cost.

Owner:叶涛

MVR energy-saving and environmentally-friendly sewage treatment system utilizing new energy

InactiveCN108622971AReduce the temperatureEmission reductionGeneral water supply conservationTreatment involving sedimentationChemical industrySteam pressure

The invention provides an MVR sewage treatment system utilizing solar energy and belongs to the technical field of energy conservation and environmental protection. A two-stage preheating / cooling modeis realized by adopting a separation subsystem and a waste heat recovery subsystem; in combination with solar subsystem preheating, and steam compression recycling in a concentration and drying subsystem, waste heat is maximally recycled, so that the cost is effectively reduced. The concentration and drying subsystem realizes the effective separation of a sewage solid, purified water and waste gas and gives full play to the advantages of a heating distillation mode for sewage treatment. According to different saturated steam pressures and temperatures, by adopting stepped utilization, the consumption of external steam is reduced by adopting stepped utilization, and the stable and continuous operation of the two sets of MVR systems is ensured. The MVR sewage treatment system has the advantages of being simple in structure, easy to realize and lower investment and operation cost, is extremely significant in energy-saving and environmentally-friendly effects and can be applied to the treatment of all kinds of sewage and sludge as well as the other fields with similar processes, such as food, feed, chemical industry, pharmacy and the like.

Owner:HARBIN UNIV OF SCI & TECH +1

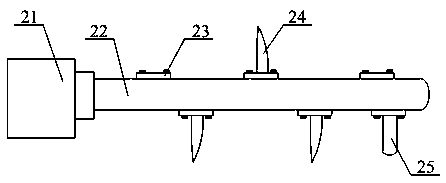

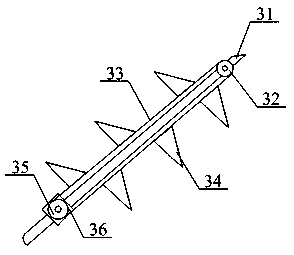

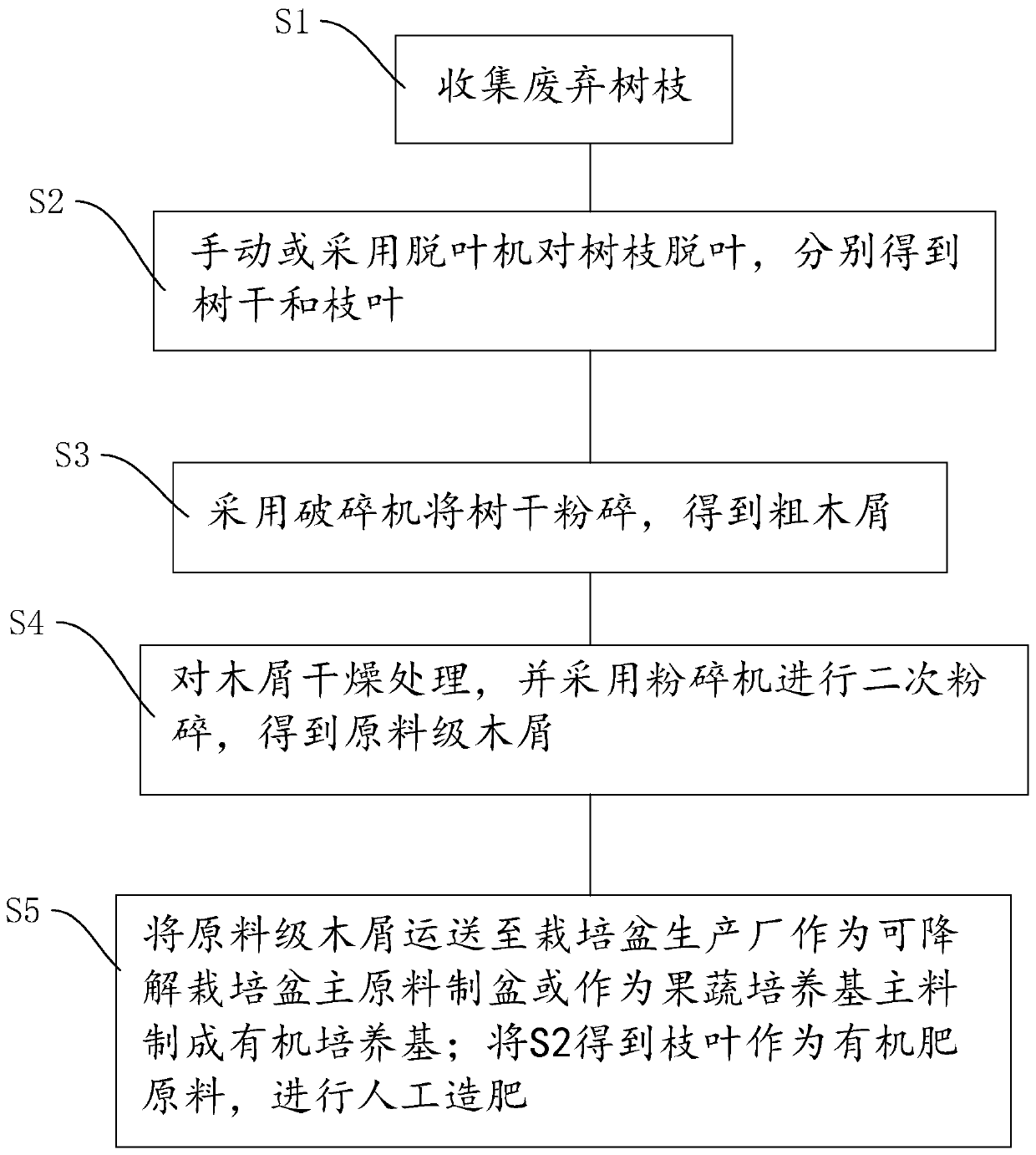

Utilization method of garden waste branches and leaf remover applied to utilization method

ActiveCN109744005AEase of environmental protectionGrowth substratesCuttersEconomic benefitsEngineering

The invention discloses a utilization method of garden waste branches and a leaf remover applied to the utilization method, and relates to a garden municipal engineering and aims at solving the problem of poor economic effect of an existing disposal method of waste branches. According to the main points of the technical scheme, the utilization comprises the steps that the waste branches are collected; the branches are removed leaves manually or by using the leaf remover to get trunks and branch leaves correspondingly; the trunks are crushed by using a crusher, and rough sawdust is obtained; the sawdust is dried and crushed twice by using the crusher to obtain raw material grade sawdust; the raw material grade sawdust is transported to a cultivation basin production plant as main raw materials of a degradable cultivation basin for basin preparing or as main materials of a fruit and vegetable culture medium to prepare a organic cultivated medium; and the branches and leaves are used as organic fertilizer raw materials for artificial fertilizer. According to the utilization method of the garden waste branches and the leaf remover applied to the utilization method, the waste branches can be treated conveniently and environmentally, and a great economic benefit is generated.

Owner:浙江天姿园林建设有限公司

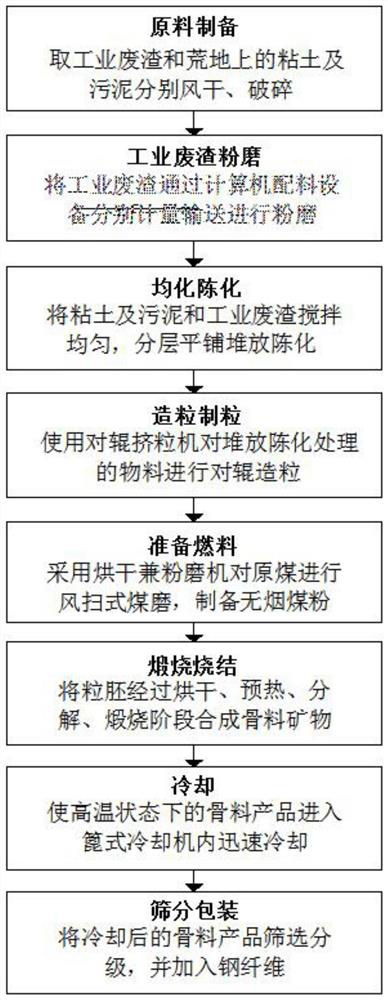

Production process of sintered building aggregate

InactiveCN111620580AWide selection of materialsUniform compositionSolid waste managementIncreasing energy efficiencyAluminateAggregate (composite)

The invention discloses a production process of a sintered building aggregate. The production process comprises the following steps: preparing raw materials, grinding industrial waste residues, homogenizing and aging, granulating, preparing a fuel, calcining and sintering, cooling, screening and packaging. Various raw materials such as shale, coal cinder, clay and sludge are matched and sintered to generate minerals such as composite aluminate to form a high-strength compact building aggregate; the nearby material selection range of factory raw materials is wide; the industrial waste residuescan be digested and treated; in addition, in the material aging process, a stacker-reclaimer is used for homogenizing the mixed materials in a tiling and direct taking storage and taking mode; the preparation method is more beneficial to uniform components of the raw materials, ensures the quality stability of the product, directly presses the materials into a cylinder which is most suitable for binding reaction with cement in the concrete product to calcine, and is beneficial to enhancing the strength of the concrete by one-time finished products.

Owner:李国安

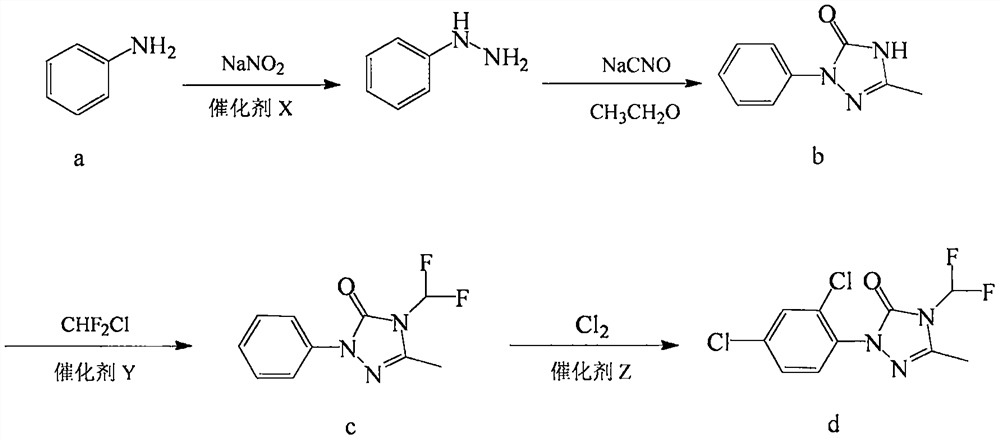

Preparation method of 1-(2,4-dichlorophenyl)-4-difluoromethyl-3-methyl-1H-1,2,4-triazole-5-one

PendingCN111689915ALow costProcess raw materials are cheap and easy to getOrganic chemistryPhysical/chemical process catalystsDichlofopmethylTriazole

The invention provides a preparation method of 1-(2,4-dichlorophenyl)-4-difluoromethyl-3-methyl-1H-1,2,4-triazole-5-one. The method comprises the steps: taking aniline as a raw material; reducing witha catalyst X to prepare phenylhydrazine; under the action of acetaldehyde and sodium cyanate, carrying out cyclization on phenylhydrazine to generate 1-phenyl-3-methyl-1H-1,2,4-triazole-5-one; carrying out a reaction on 1-phenyl-3-methyl-1H-1,2,4-triazole-5-one and monochlorodifluoromethane under the action of a catalyst Y to generate 1-phenyl-3-methyl-4-difluoromethyl-1H-1,2,4-triazole-5-one, and carrying out catalytic chlorination through a catalyst Z to prepare 1-(2,4-dichlorophenyl)-4-difluoromethyl-3-methyl-1H-1,2,4-triazole-5-one.

Owner:湖南斯派克科技股份有限公司

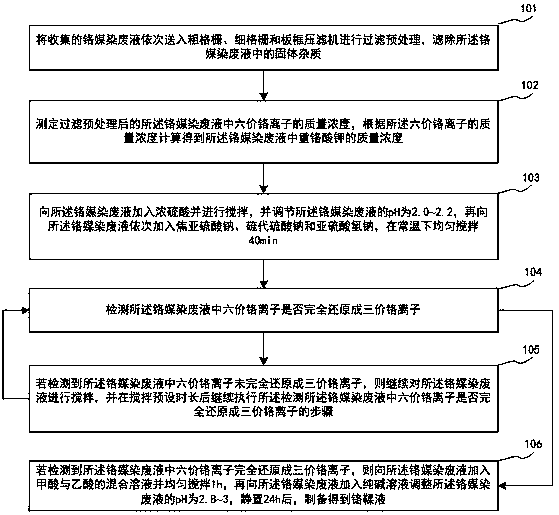

Preparation method of chrome tanning solution

ActiveCN109097508AAdvantages of preparation methodEase of environmental protectionTanning treatmentLiquid wasteReducing agent

The invention discloses a preparation method of a chrome tanning solution and relates to the technical field of environmental protection. According to the preparation method of the chrome tanning solution, reducing agents such as sodium pyrosulfite, sodium hydrogen sulfite, sodium thiosulfate and the like are reasonably selected for use, high-toxicity sexivalent chromium ions which are not prone to settling separation in chrome mordanting liquid waste are reduced into trivalent chromic ions with lower toxicity under the acidic condition, and the chrome mordanting liquid waste can be environmentally treated simply and effectively; further, the chrome mordanting liquid waste structure obtained after reduction is adjusted by sulfuric acid, formic acid, acetic acid, sodium carbonate and the like, so that the chrome tanning solution with good masking performance and acid and alkali resistant stability is prepared from the chrome mordanting liquid waste, resourceful treatment of the chrome mordanting liquid waste is realized, environmental pollution caused by toxicity of the chrome mordanting liquid waste is reduced, and the preparation method meets the time requirement of sustainable development.

Owner:JIAXING UNIV

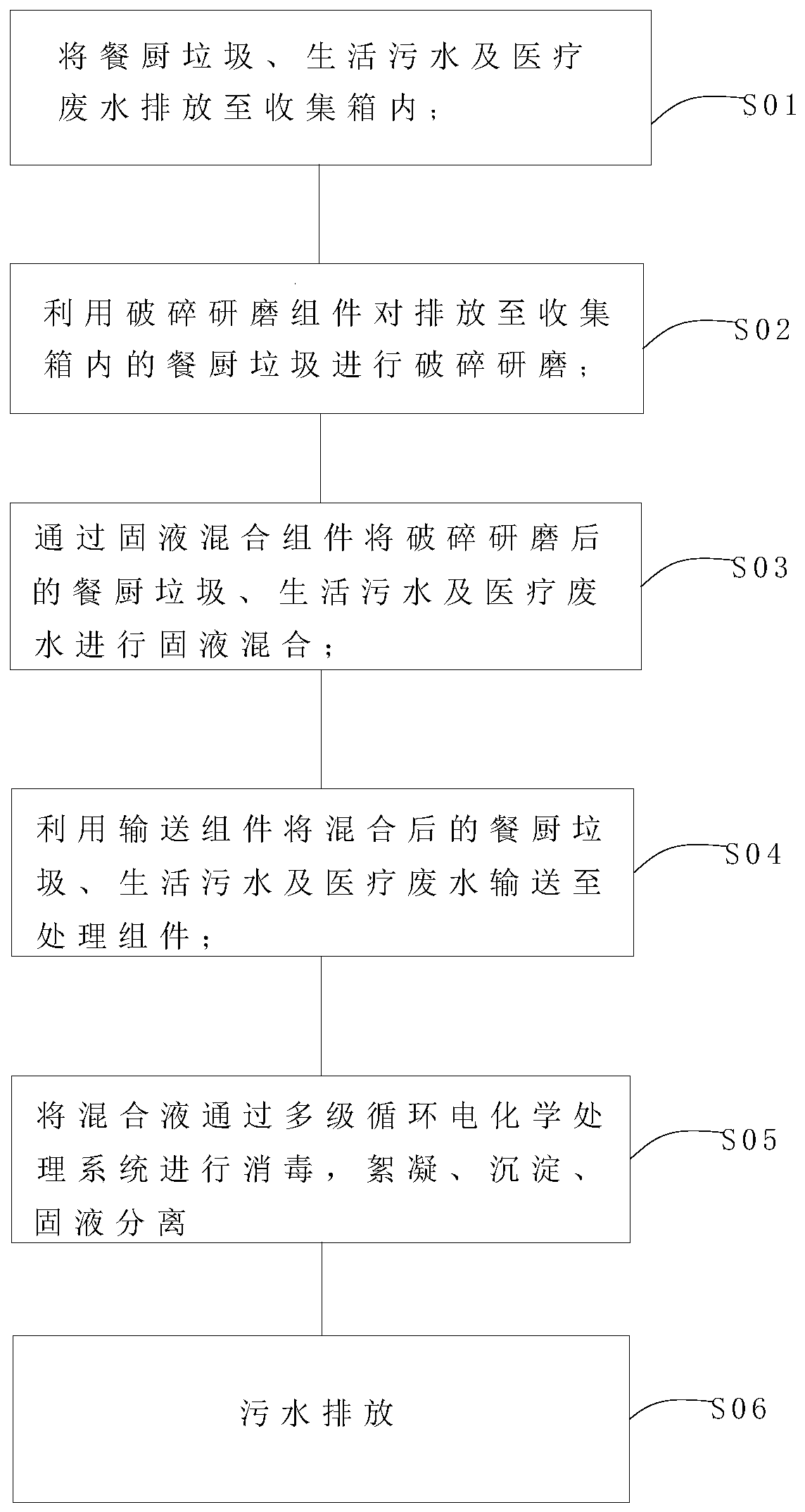

Comprehensive collection and treatment device and method for kitchen waste, domestic sewage and medical wastewater

PendingCN111573912AConvenient integrated comprehensive collectionEasy to handleSpecific water treatment objectivesMultistage water/sewage treatmentWastewaterSewage

The invention discloses a comprehensive collection and treatment device and method for kitchen waste, domestic sewage and medical wastewater. The comprehensive collection and treatment device comprises a collection assembly, a conveying assembly and a treatment assembly. The collection assembly comprises a collecting box and a collecting pipeline, wherein the collecting pipeline is used for discharging kitchen waste, domestic sewage and medical wastewater into the collecting box; the conveying assembly is connected with the collecting box and the treatment assembly and used for conveying the kitchen waste, the domestic sewage and the medical wastewater collected by the collecting box to the treatment assembly; and the treatment assembly is used for conducting electrochemical treatment on the kitchen waste, the domestic sewage and the medical wastewater conveyed by the conveying assembly and discharging the kitchen waste, the domestic sewage and the medical wastewater. The working efficiency of a ship sewage treatment system is improved, the size and the capacity of the ship sewage treatment system are reduced, and manufacturing cost is reduced. In addition, the invention further discloses a method based on the comprehensive collection and integrated treatment device for the kitchen waste, the domestic sewage and the medical wastewater. The method has the advantages of simple system structure, safety, reliability and high treatment efficiency.

Owner:GUANGZHOU WEI YE MARINE EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com