Environment-friendly high-efficiency modified asphalt waterproof roll mixing device and process

A technology of modified asphalt and waterproof membrane, which is applied in the direction of building insulation materials, building components, buildings, etc. It can solve the problems of large mixing load, long mixing time, and difficulty in high-speed mixing, and achieves convenient waste gas treatment and environmental friendliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

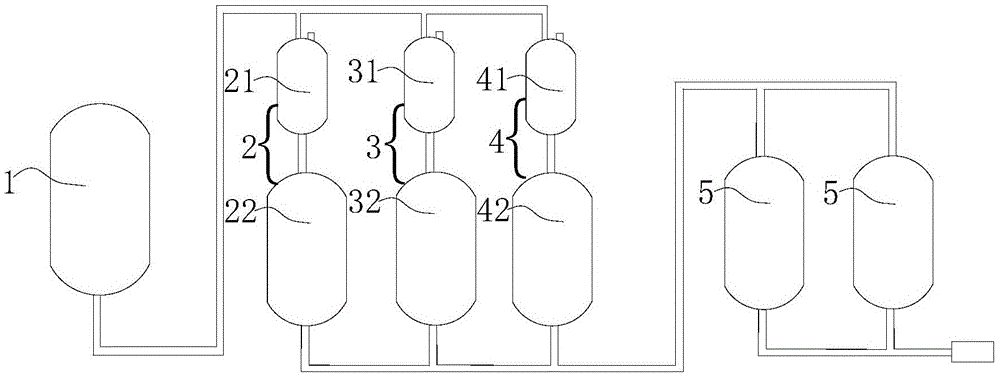

[0032] Attached belowfigure 1 , and further illustrate the technical solution of the present invention through specific embodiments.

[0033] Such as figure 1 As shown, an environmentally friendly and efficient batching device for modified asphalt waterproof coiled material of the present invention includes an asphalt preheating kettle 1 connected to each other through pipelines, a tire powder batching kettle 2, a filler batching kettle 3, and an SBS modifier batching Kettle 4 and modified asphalt batching kettle 5, tire powder batching kettle 2, filler batching kettle 3 and SBS modifier batching kettle 4 are connected in parallel through mixing pipes, and the outlet of asphalt preheating kettle 1 is connected with tire powder batching kettle respectively. Kettle 2, filling material batching kettle 3 and the inlet of SBS modifier batching kettle 4 are connected, and the outlets of tire powder batching kettle 2, filler batching kettle 3 and SBS modifier batching kettle 4 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com