Equipment for preparing carbon disulfide with circulating fluidized bed

A circulating fluidized bed and carbon disulfide technology is applied in the field of equipment for preparing carbon disulfide in a circulating fluidized bed, and achieves the effects of easy fabrication, low cost and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

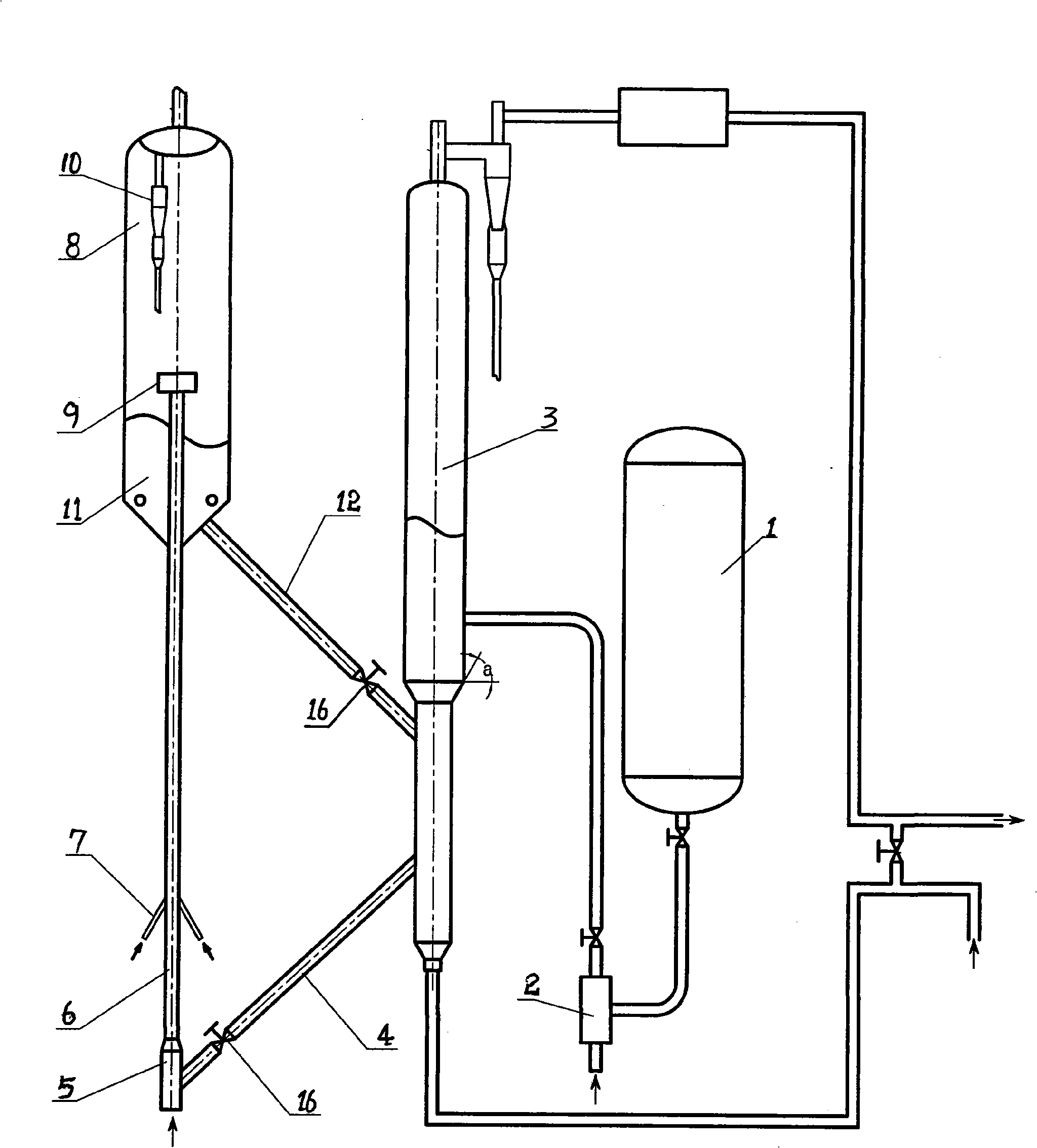

[0025] Embodiment 1: as figure 1 Shown, it is the side-by-side structure described in the present invention

[0026] The equipment for preparing carbon disulfide in a circulating fluidized bed includes a silo 1, a feeder 2 and a fluidized bed heating furnace 3 connected to the feeder 2 through a pipeline. The diameter of the lower part of the fluidized bed heating furnace is smaller than that of the upper part; the fluidized bed heating furnace 3 is provided with a hot charcoal pipeline 4, the other end of the hot charcoal pipeline 4 communicates with the pre-lifter 5, and a riser 6 is connected above the pre-lifter 5, and a nozzle 7 is arranged on the riser 6, and the upper end of the riser 6 extends into the settler 8. A quick separation device 9 is installed at the end, the quick separation device is a cyclone separator, a cyclone separator 10 is arranged at the top of the settler, a stripping section 11 is arranged at the bottom of the settler, and a fluidized bed heating ...

Embodiment 2

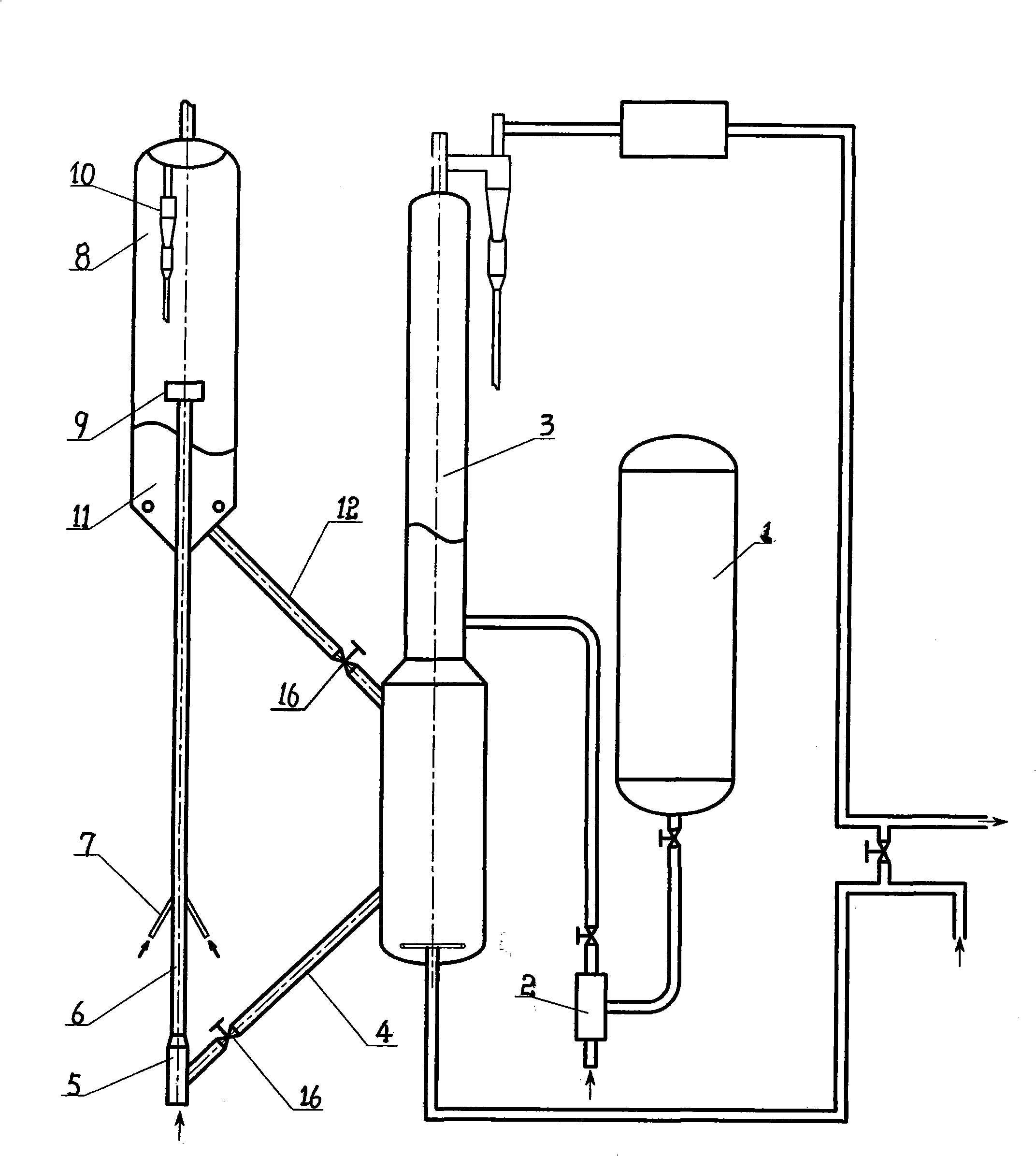

[0028] Embodiment 2: as figure 2 Shown, is the parallel structure of the present invention

[0029] The difference from Example 1 is only that the upper diameter of the fluidized bed heating furnace is smaller than the lower diameter. In actual operation, the dilute phase velocity is increased to artificially reduce the efficiency of the cyclone separator to discharge the burned fly ash.

Embodiment 3

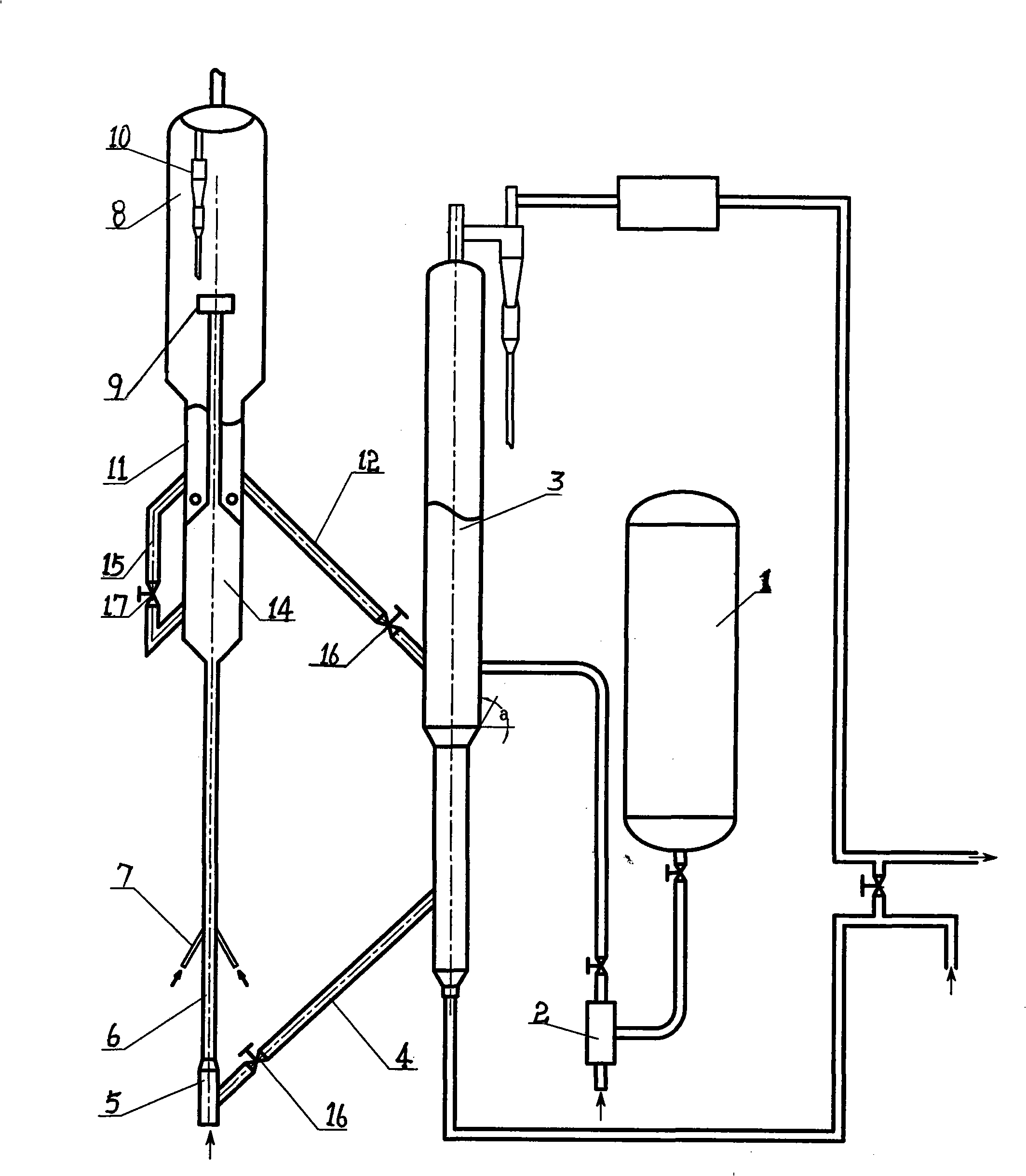

[0030] Embodiment 3: as image 3 Shown, is the parallel structure of the present invention

[0031] The difference with embodiment 1 is that a fluidized bed 14 is added in the middle of the riser 6 to prolong the reaction time. The diameter of the fluidized bed is greater than the diameter of the riser, and the diameter of the fluidized bed and its size are determined by the required reaction time ; In order to maintain the material level of the fluidized bed layer, the fluidized bed layer and the stripping section below the settler are connected through a circular tube, and a valve is installed on the circular tube to control the flow rate of the material body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com