Immersed multi-stage flue gas environment-friendly desulfurization tower

An immersion, desulfurization tower technology, applied in the field of immersion multi-stage flue gas environmental protection desulfurization towers, can solve the problems of environmental protection facility operation safety threats, increase the construction cost of environmental protection facilities, increase the height of desulfurization towers, etc., achieve fast desulfurization efficiency, Reduced height and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

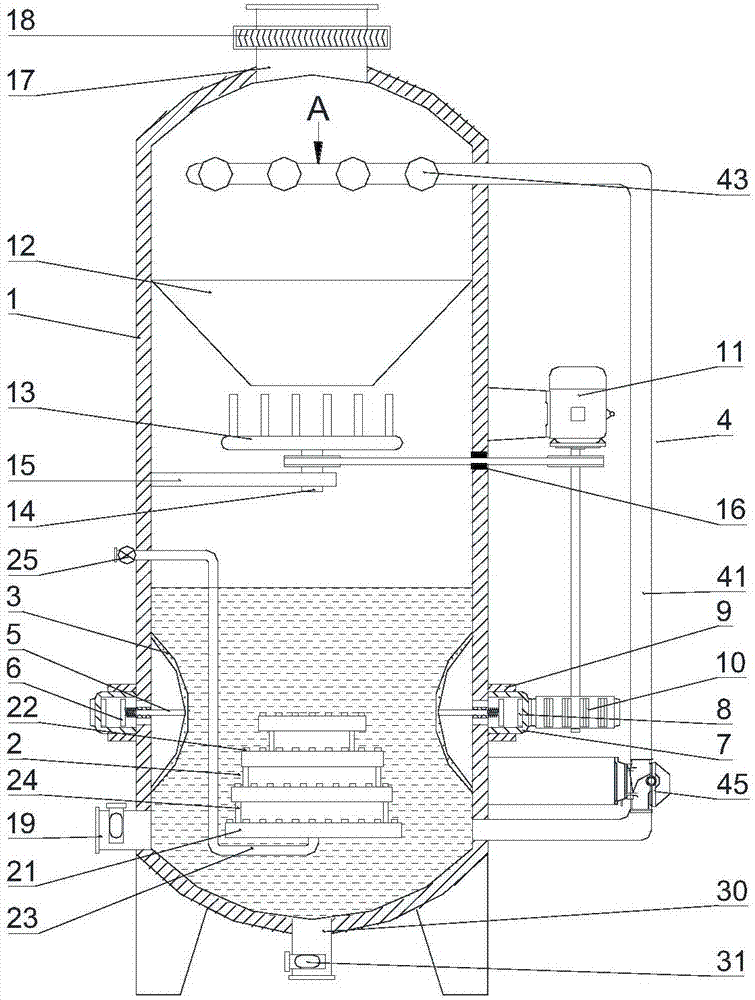

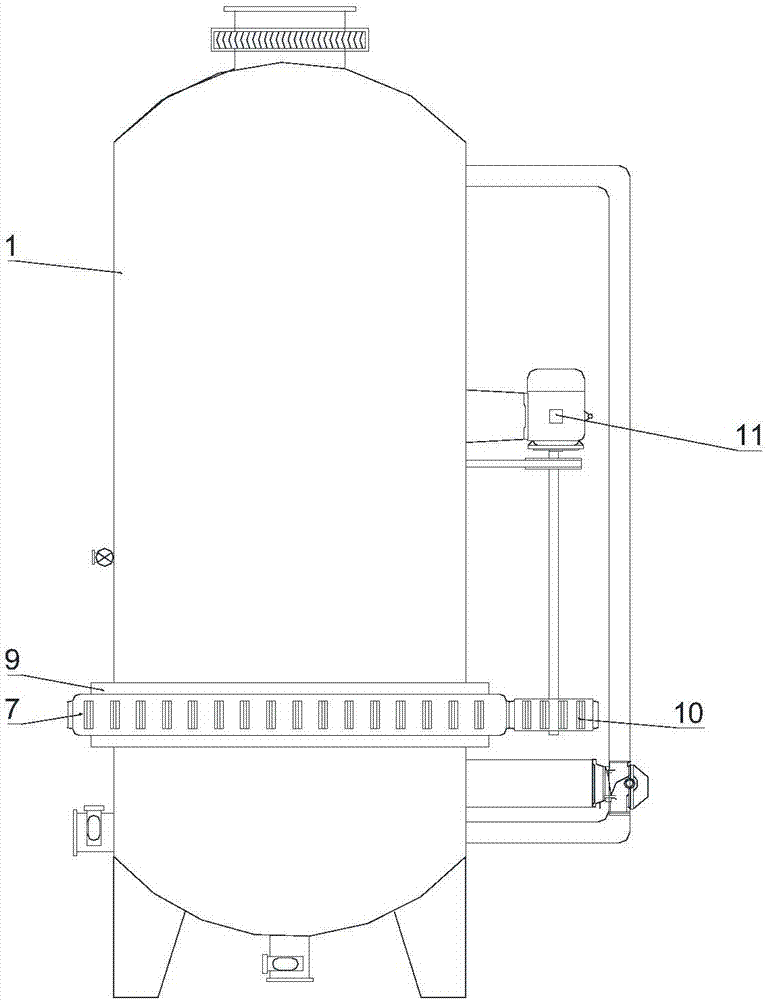

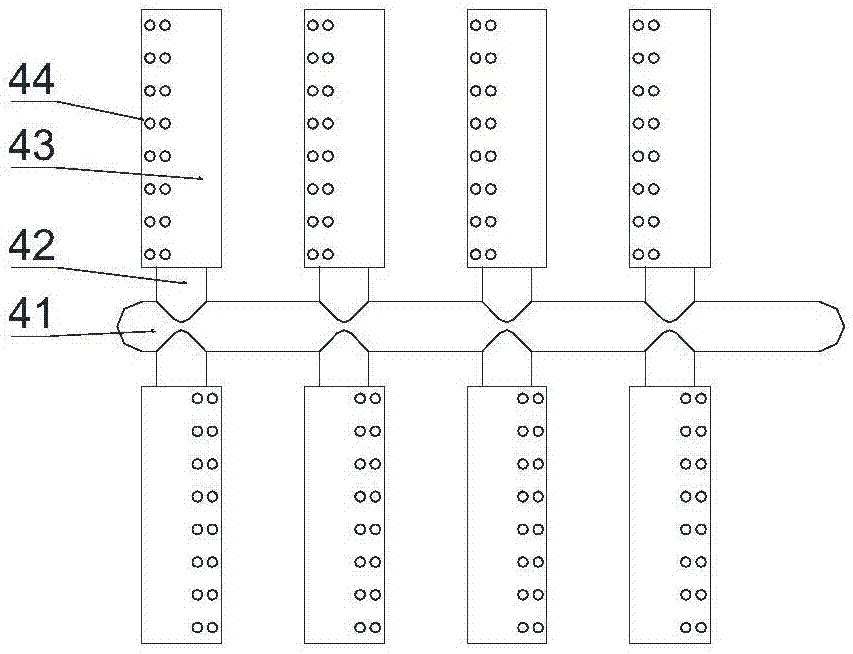

[0018] see Figure 1-3 , a submerged multi-stage flue gas environmental protection desulfurization tower, comprising a tower body 1, the inner lower side of the tower body 1 is equipped with an alkaline absorbent, and the inner lower side of the tower body 1 is provided with a ring-shaped flue gas overflow device 2, the smoke overflow device 2 is composed of several layers of annular pipes 21, overflow branch pipes 22 opened on the surface of the annular pipes 21, and connecting pipes 24 connecting adjacent annular pipes 21, the smoke overflow device 2 is connected with an air intake pipe 23, and the upper end of the air intake pipe 23 is fixed and runs through the middle of the side wall of the tower body 1. A number of vibrating membranes 3 are arranged on the inner lower side of the tower body 1, and the edge side of the vibrating membrane 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com