Multi -Channeled Flat Tube And Heat Exchanger

a flat tube and multi-channel technology, applied in the field of construction, can solve the problems of reducing the contact surface area between the outer surface of the tube and the fin, reducing the heat transfer performance, and unable to achieve desired performance, and achieve the effect of increasing heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

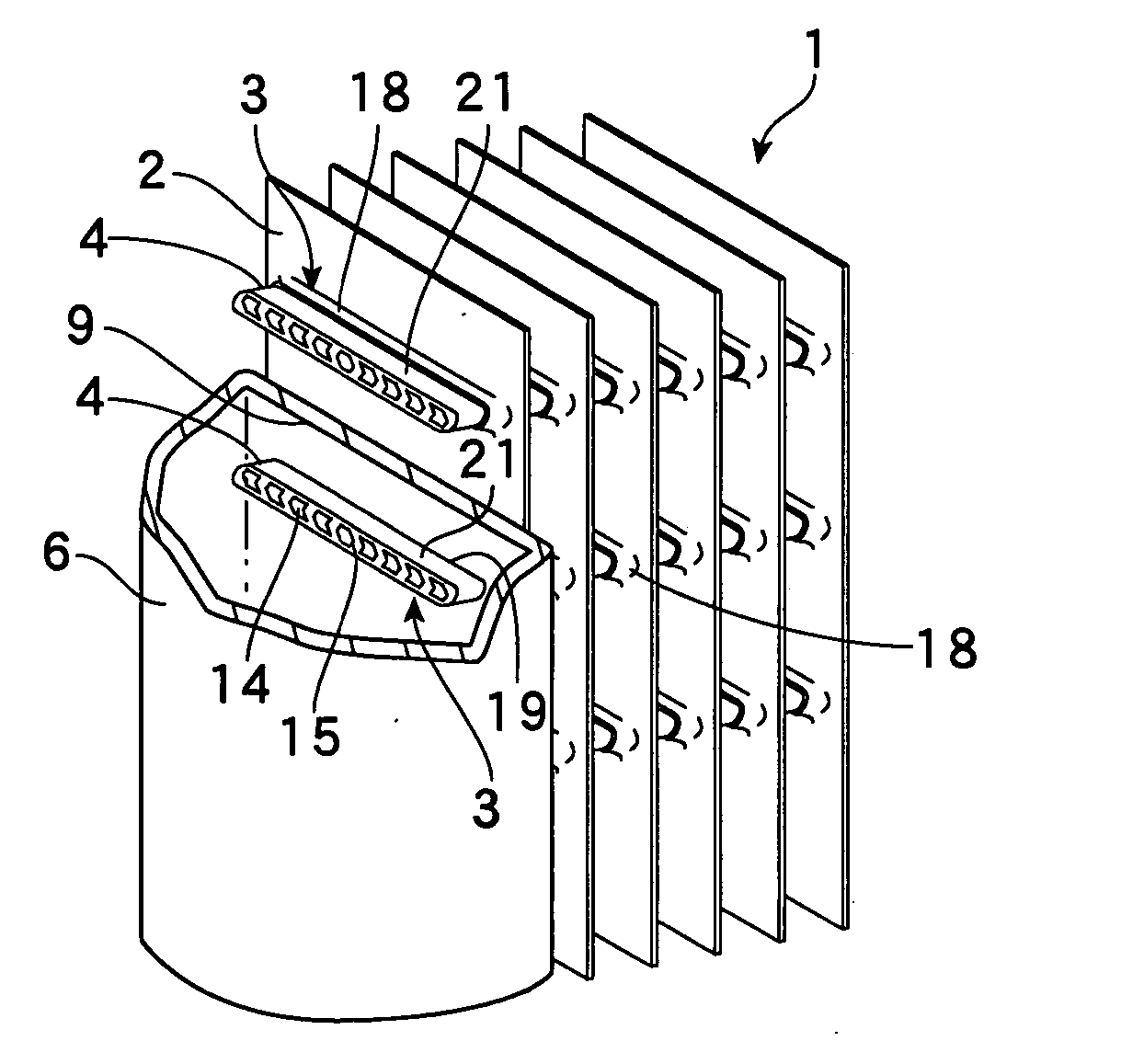

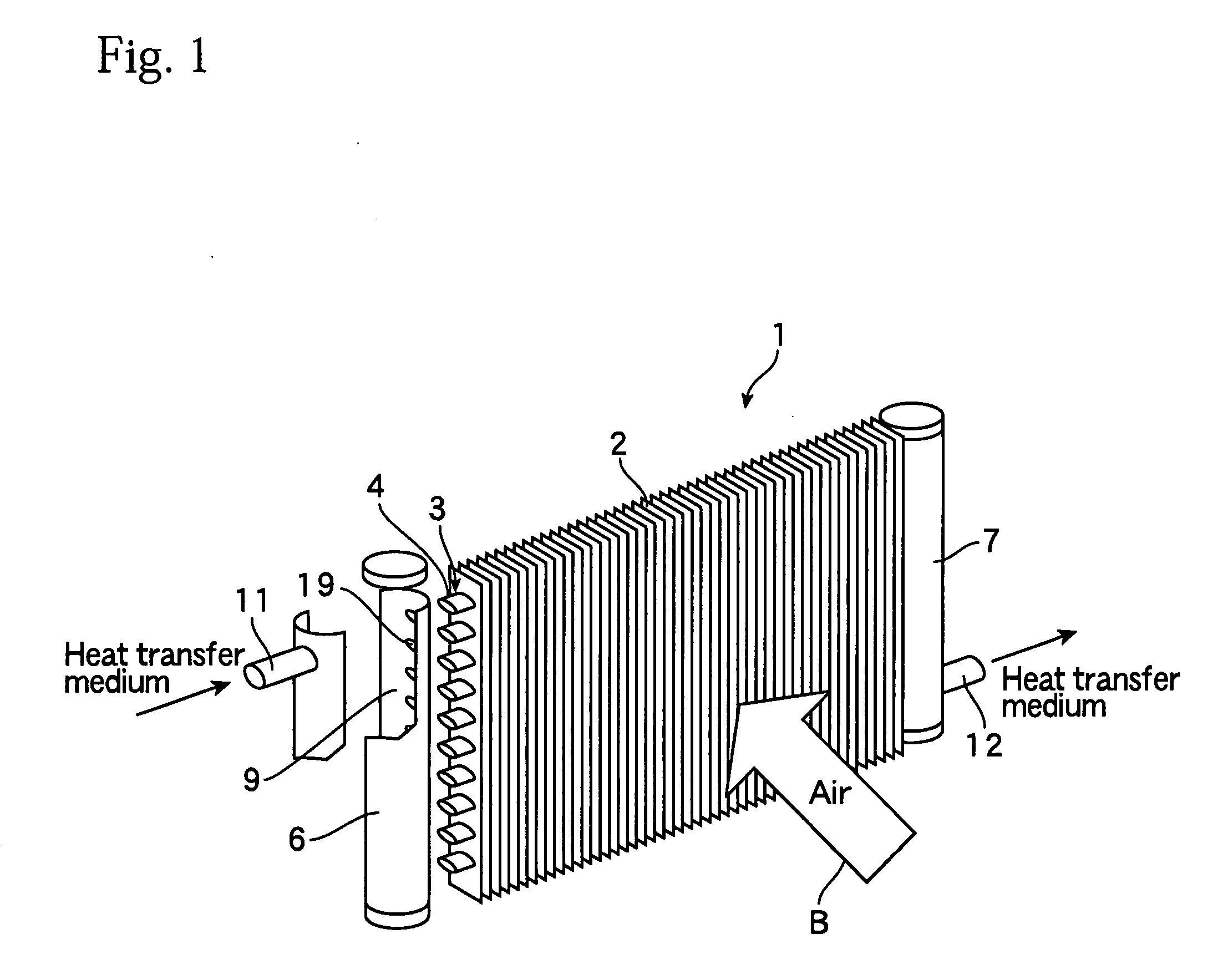

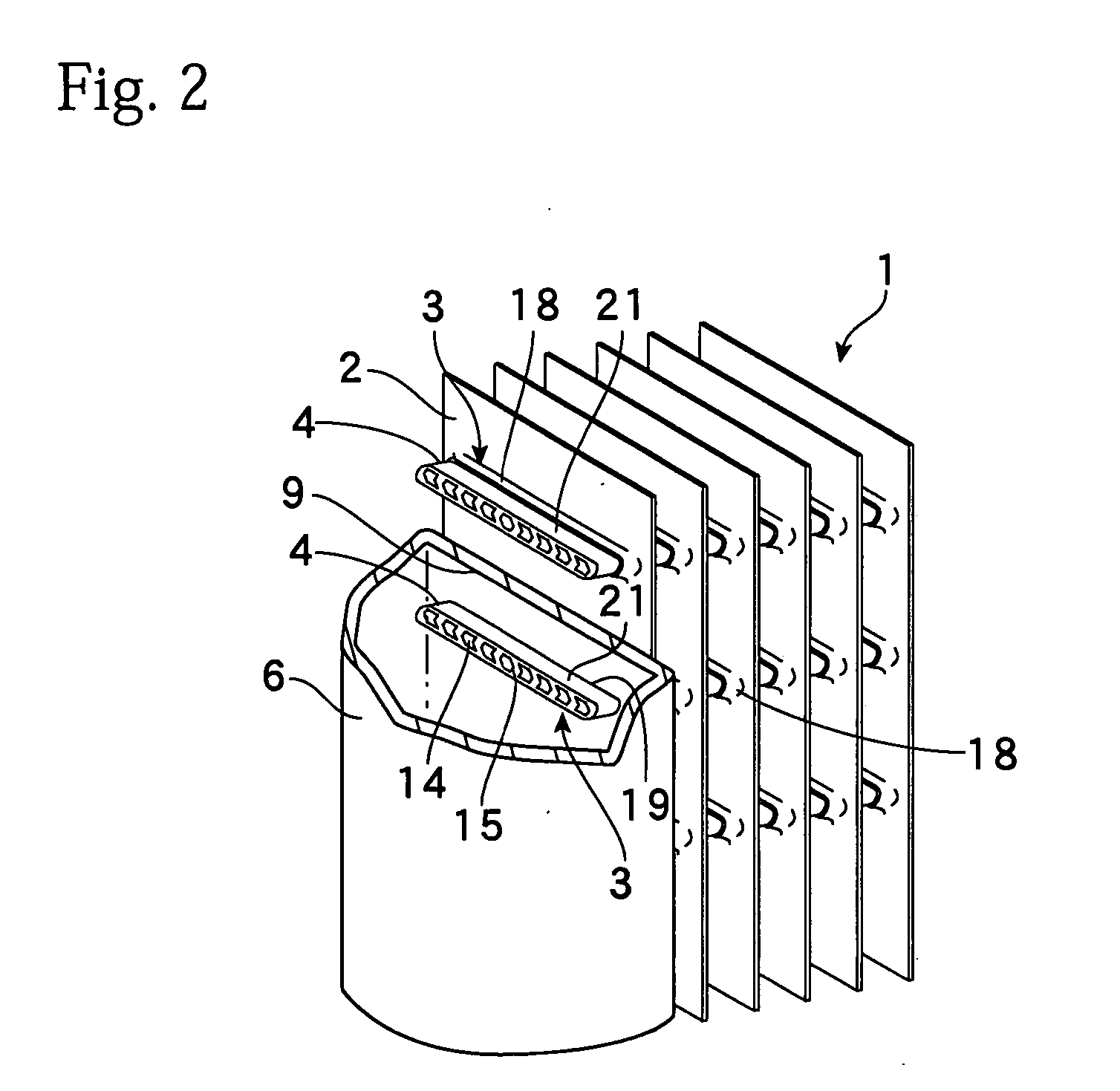

[0025]FIG. 1 schematically shows a heat exchanger that uses multi-channeled flat tubes. FIG. 2 is a perspective view showing an enlargement of a state where the multi-channeled flat tubes have been expanded. The heat exchanger 1 is a plate fin-type heat exchanger. The heat exchanger 1 has a plurality of plate-like fins 2 disposed in parallel at regular intervals and a plurality of multi-channeled flat tubes 3 that are disposed in parallel and are joined to the fins 2 in a state where the multi-channeled flat tubes 3 pass through the fins 2. Each multi-channeled flat tube (flat multi-channeled tube, multi-channel flat tube) 3 is constructed so that the inside of a flat outer tube 21 is divided into a plurality of parallel channels 14 by a plurality of partitions 15. End parts 4 at both ends of the multi-channeled flat tubes 3 are connected to joining holes 19 formed in side walls 9 of headers 6 and 7 positioned on the left and right sides of the heat exchanger 1. A heat transfer medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com