Environment-friendly water-based gas-phase long-acting antirust solution composition, preparation method and use method

A technology of anti-rust liquid and composition, applied in lubricating composition, petroleum industry, etc., can solve the problems of not being suitable for long-term anti-rust protection, not having gas-phase anti-rust performance, affecting surface quality and precision, etc., and achieving excellent contact Anti-rust ability, meet long-term anti-rust requirements, easy to clean and water treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

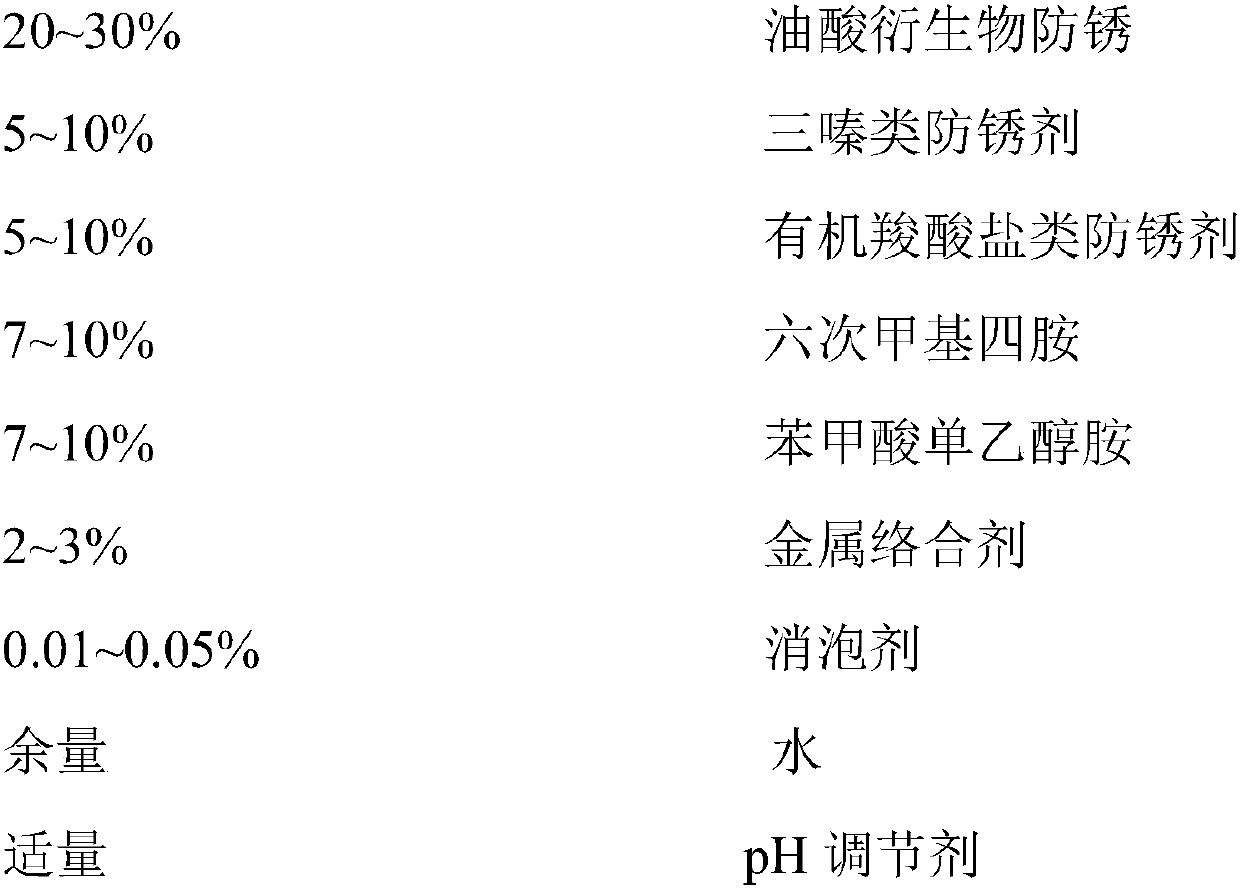

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description. The 2,4,6-tris(aminocaproic acid group)-1,3,5-triazine rust inhibitor mentioned in this patent is preferably VG-F101 (Shenyang Xijin Chemical Technology Co., Ltd.) or NEUF 726 (North Thai Biotechnology Co., Ltd.), the organic carboxylate rust inhibitor is preferably VG-G201 (Shenyang Xijin Chemical Technology Co., Ltd.) or NEUF Y-80S (Nuotai Biotechnology Co., Ltd.); the defoamer is organosilicon modified Polyether defoamer, preferably VG-X10 (Shenyang Xijin Chemical Technology Co., Ltd.); methylene benzotriazole preferably VG-F102 (Shenyang Xijin Chemical Technology Co., Ltd.) or NEUF 714 (Nuotai Biotechnology Co., Ltd.) .

[0044] The preparation method of oleic acid derivative antirust agent:

[0045] Accurately weigh 24g of oleic acid and add it to the reaction kettle, pass in nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com