Process for preparing carbon disulphide by using circulating fluid bed

A technology of circulating fluidized bed and carbon disulfide, which is applied in the technical field of preparing carbon disulfide in a circulating fluidized bed, can solve the problems of discontinuous production process, low production efficiency, high labor intensity, etc. effects of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

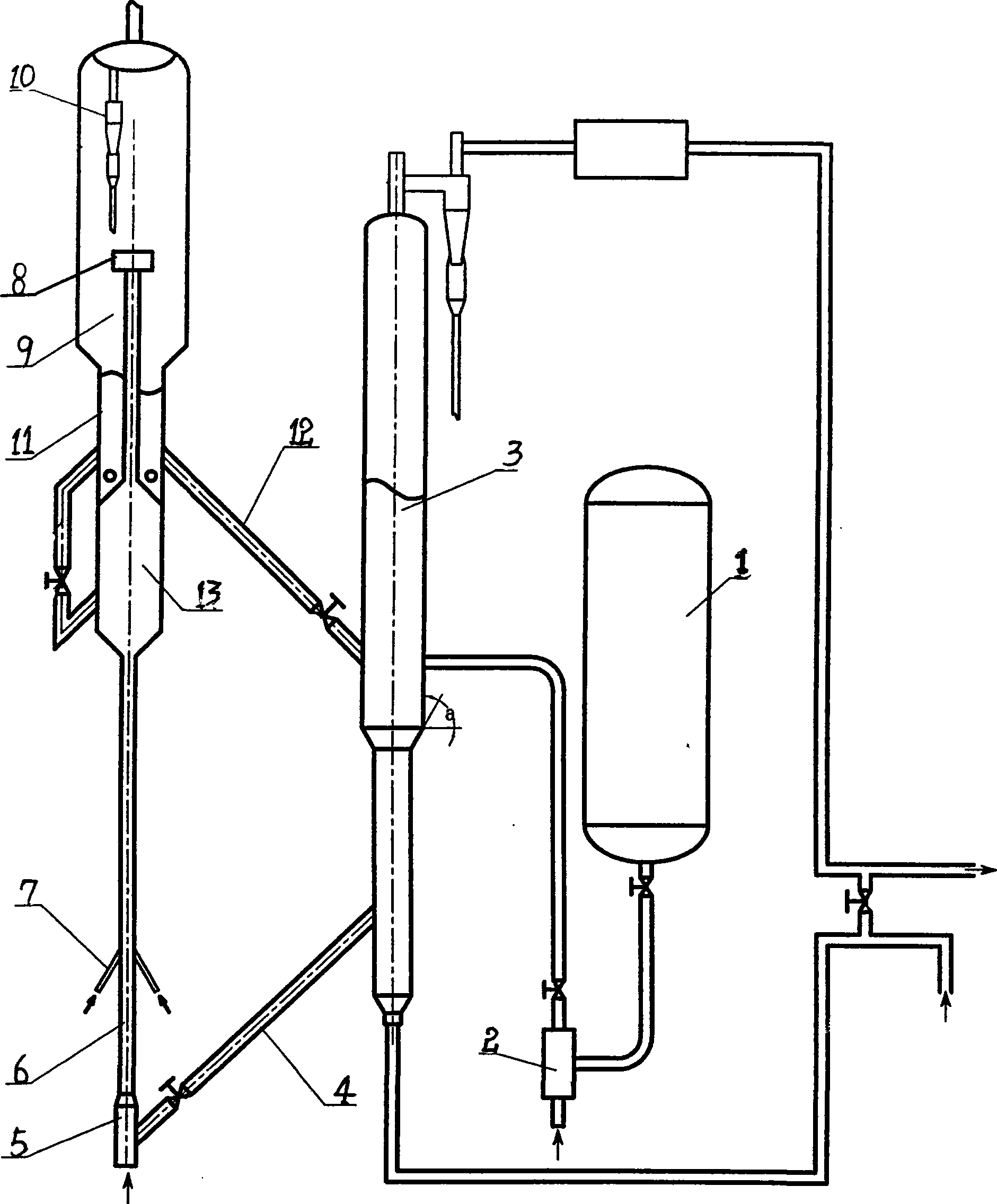

[0023] A kind of technique that circulating fluidized bed prepares carbon disulfide, as figure 1 As shown, the specific steps are as follows:

[0024] (1) The carbon-containing solid matter is transported to the fluidized bed heating furnace 3 through the silo 1 and the feeder 2, and the temperature in the fluidized bed heating furnace 3 is controlled at 700-1200 ° C, and burned after being fluidized and burned by air Part of the carbon-containing solid matter releases heat to heat the remaining carbon-containing solid matter at the same time; (2) The heated carbon-containing solid matter enters the pre-lifter 5 through the hot charcoal pipeline 4, and moves along the riser tube under the action of the gas medium below the pre-lifter. 6 flows upward, the temperature in the riser 6 is controlled at 500-900°C, preferably 700-850°C, the gas medium below the pre-lifter 5 is selected from inert gas or carbon disulfide gas, and the superficial velocity of the mixed gas in the riser ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com