Synthesis method of lamellar ZSM-5 zeolite

A technology of ZSM-5 and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve problems such as difficulty in large-scale application, high synthesis cost, and environmental pollution. Achieve the effects of low synthesis cost, improved reaction performance, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

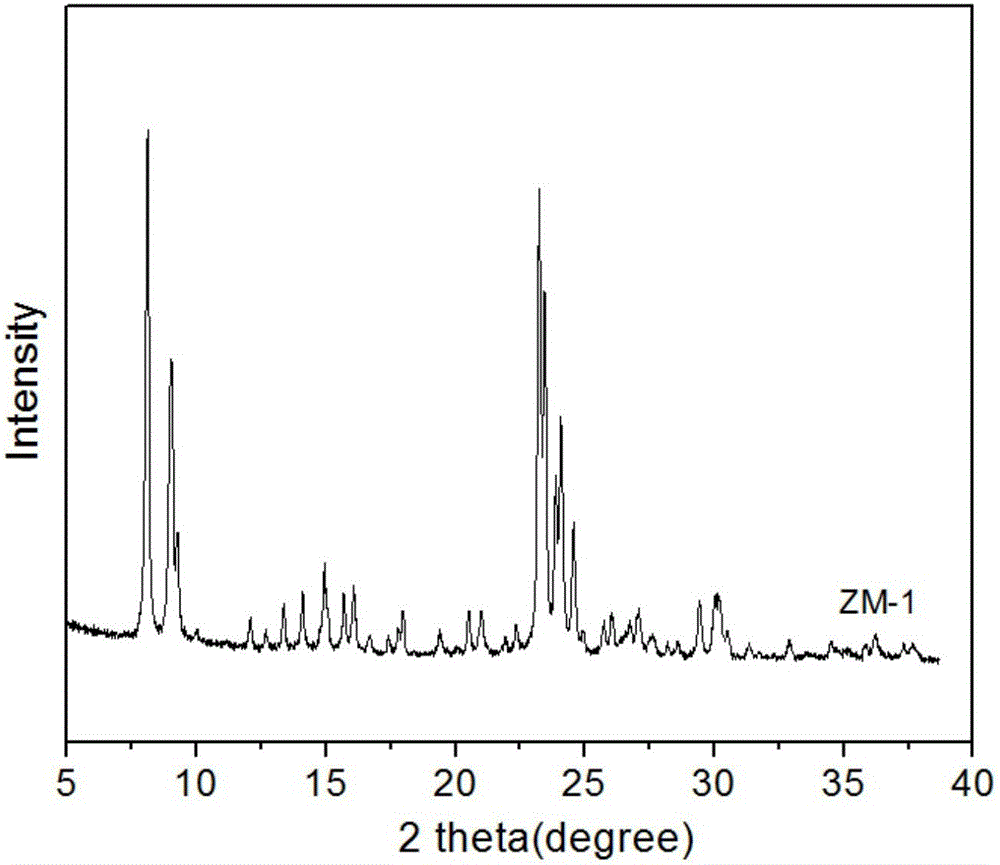

Embodiment 1

[0029] A kind of synthetic method of thin-layer ZSM-5 zeolite, comprises the steps: 5g micron ZSM-5 molecular sieve (particle diameter is about 7 μm) crystal seed is used 50ml 3wt% sodium hydroxide solution at 40 ℃ and stirs pretreatment 5h , as a seed solution for later use.

[0030] 150g tetraethyl orthosilicate (TEOS) (technical grade, SiO 2 ≥30wt%) was dispersed in 70g of desalted water, then 80g of NaOH solution with a mass fraction of 10% was added, and fully stirred at room temperature for 0.5 hours to prepare A solution;

[0031] Mix 70g of desalinated water and 4.1g of aluminum sulfate octadecahydrate, stir and fully dissolve at room temperature for 0.5 hours to prepare B solution;

[0032] Slowly add solution B into solution A, stir well at room temperature for 1 hour, then add 20 g of the above-mentioned seed liquid under stirring conditions, and adjust the pH value of the system to about 10 with hydrochloric acid solution to form a uniform gel, and then transfer t...

Embodiment 2

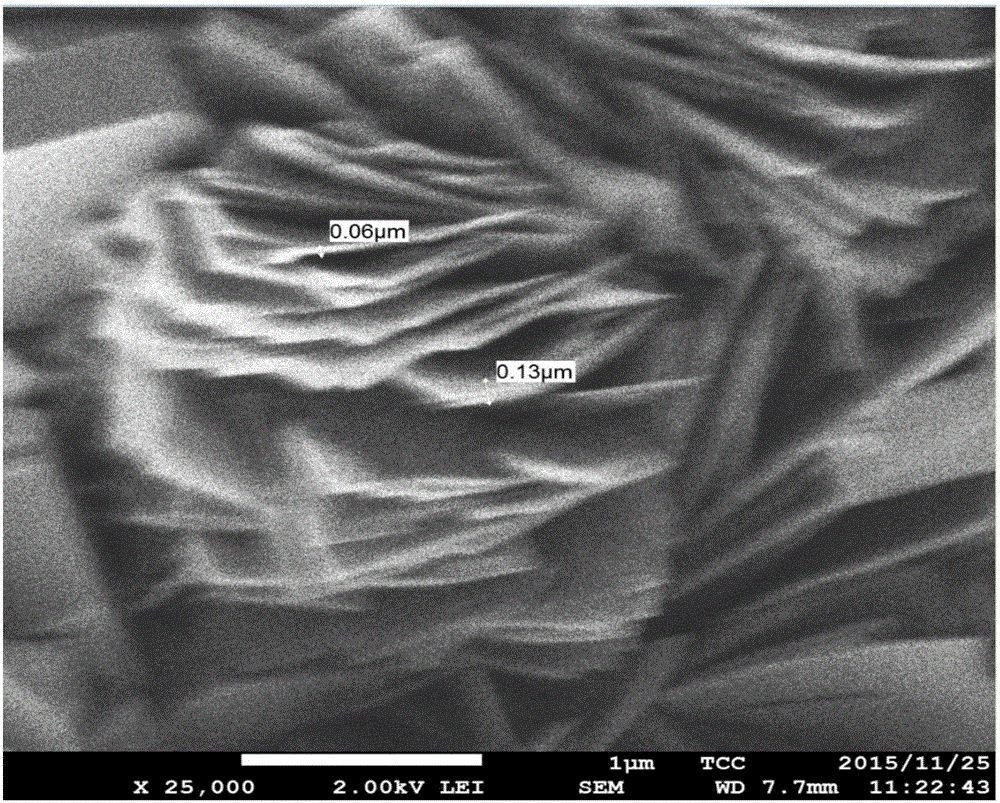

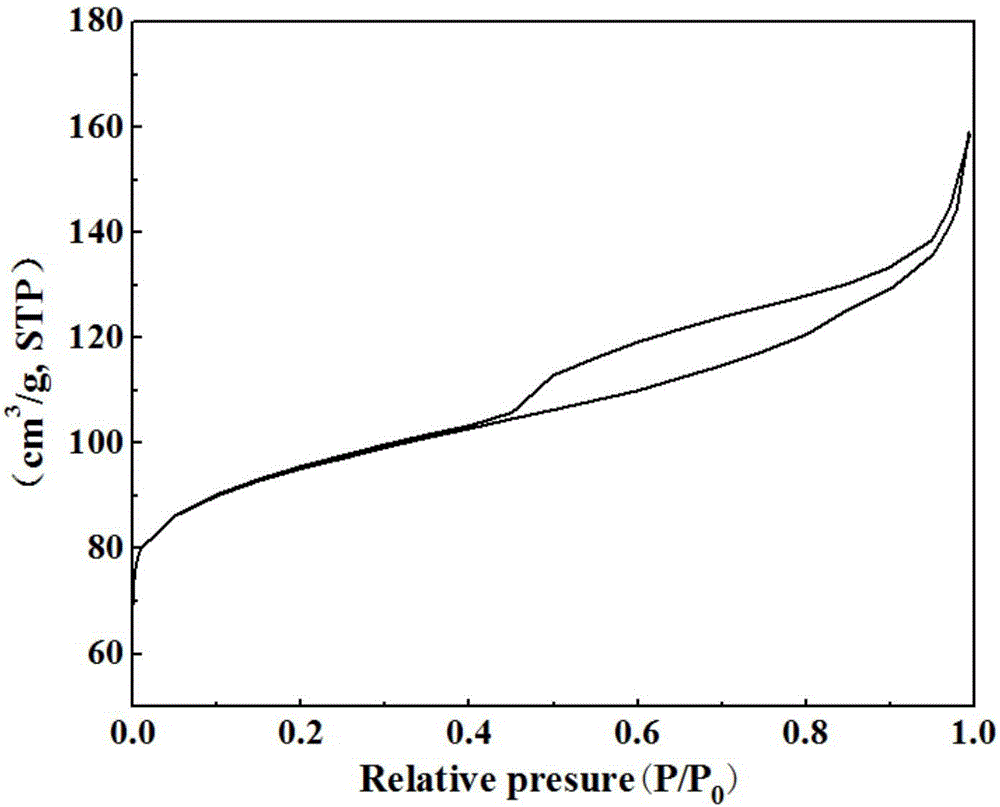

[0034] Repeat Example 1, but change the micron ZSM-5 zeolite to nano ZSM-5 zeolite in the seed crystal, and change the mass fraction of sodium hydroxide from 3 wt% to 5 wt%. Other conditions remain unchanged. The relative crystallinity of the obtained zeolite sample was characterized as 96%, and the thin layer thickness of the sample characterized by scanning electron microscope was 40nm. The specific surface area of the nitrogen physical adsorption test sample is 520m 2 / g, the total pore volume is 0.32cm 3 / g.

Embodiment 3

[0036] Repeat Example 1, but change TEOS to silica sol, change aluminum sulfate to sodium aluminate, and change the crystallization temperature to 185°C. Other conditions remain unchanged. The relative crystallinity of the obtained zeolite sample was characterized as 93%, and the thin layer thickness of the sample was characterized by a scanning electron microscope as 60 nm. The specific surface area of the nitrogen physical adsorption test sample is 500m 2 / g, the total pore volume is 0.29cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com