Dry distillation production process for lignite or high volatile coal

A technology with high volatile content and production process, applied in the field of coal dry distillation process, can solve the problems of high value, singleness, and increasing difficulty in industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

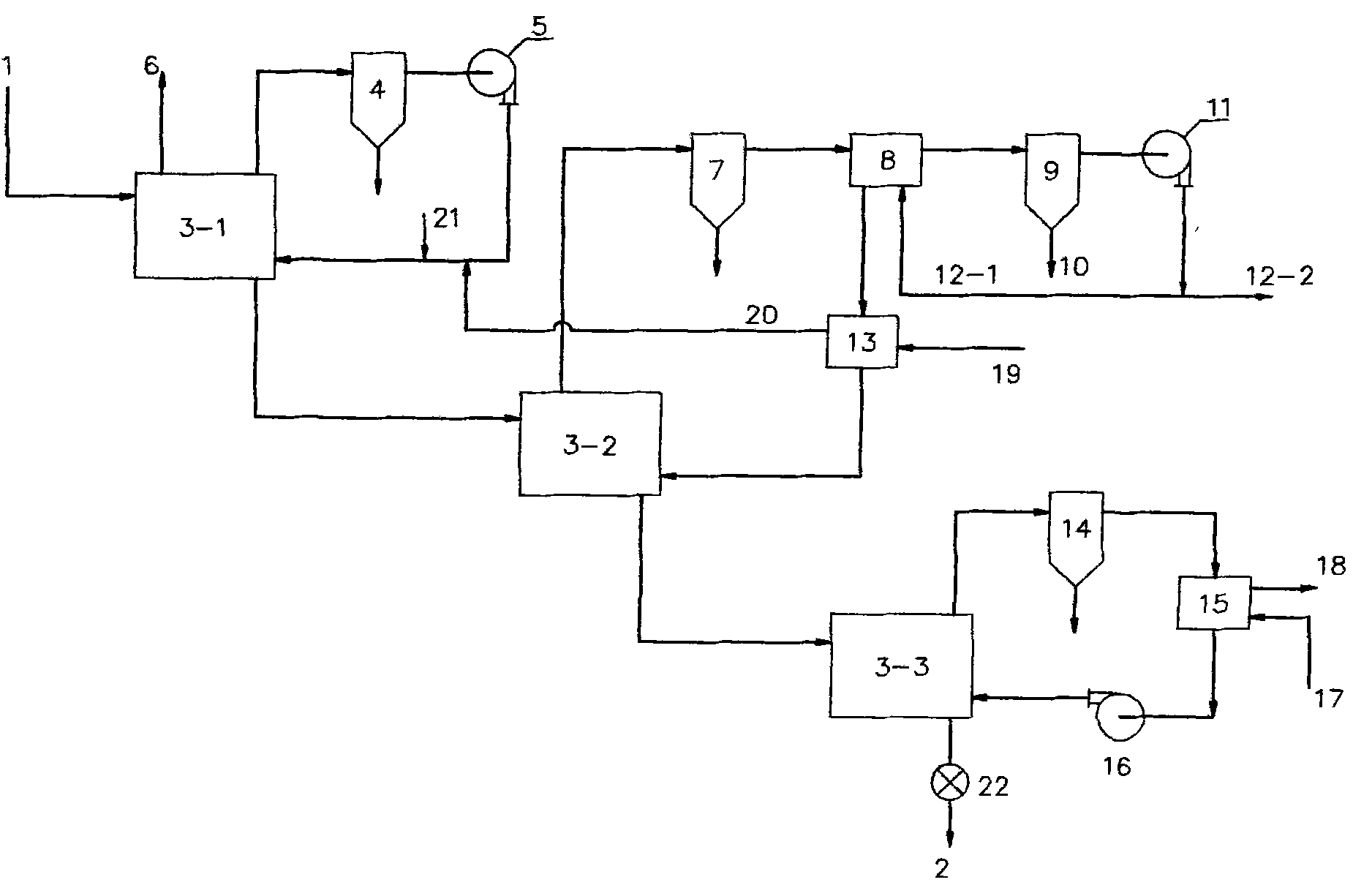

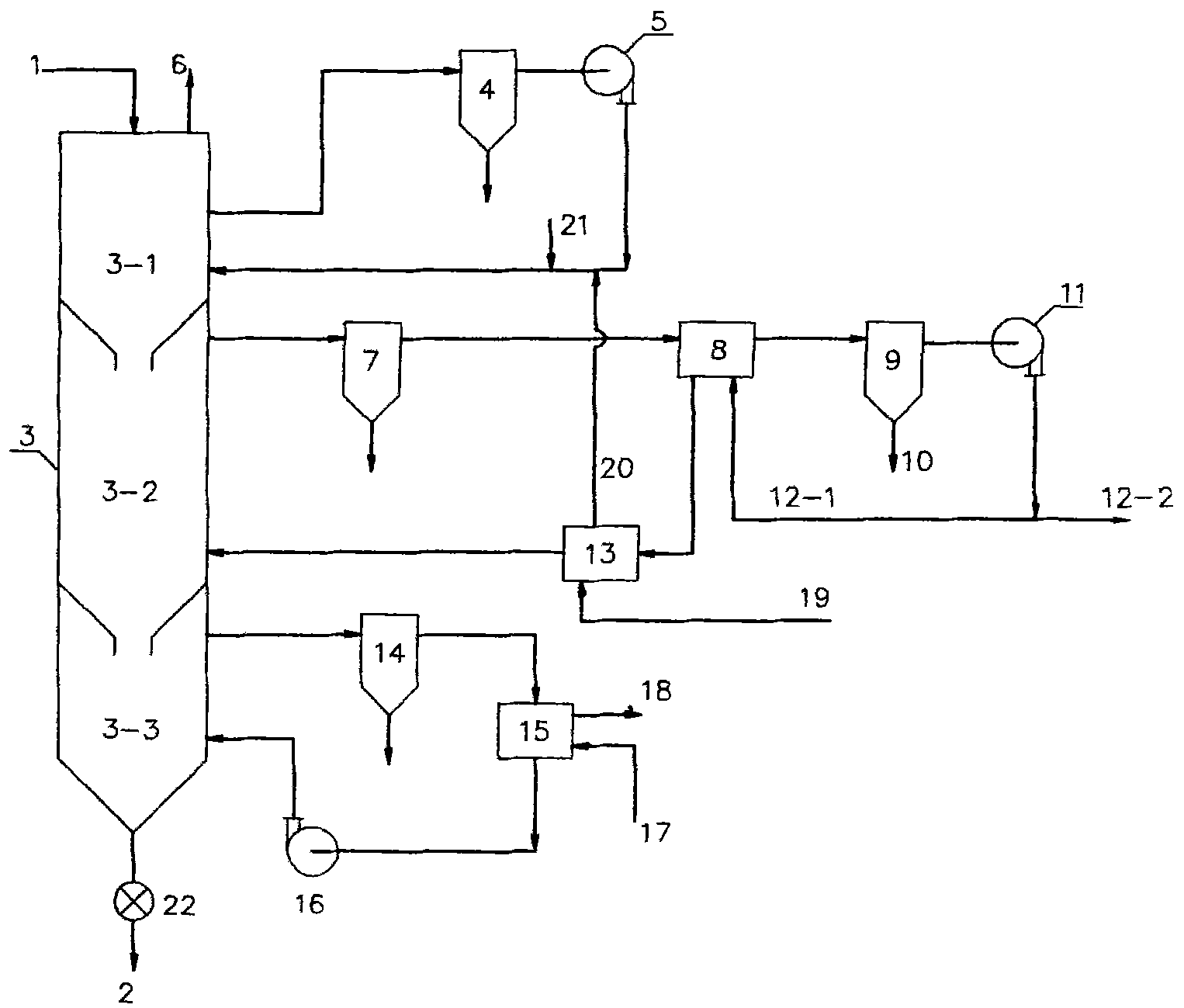

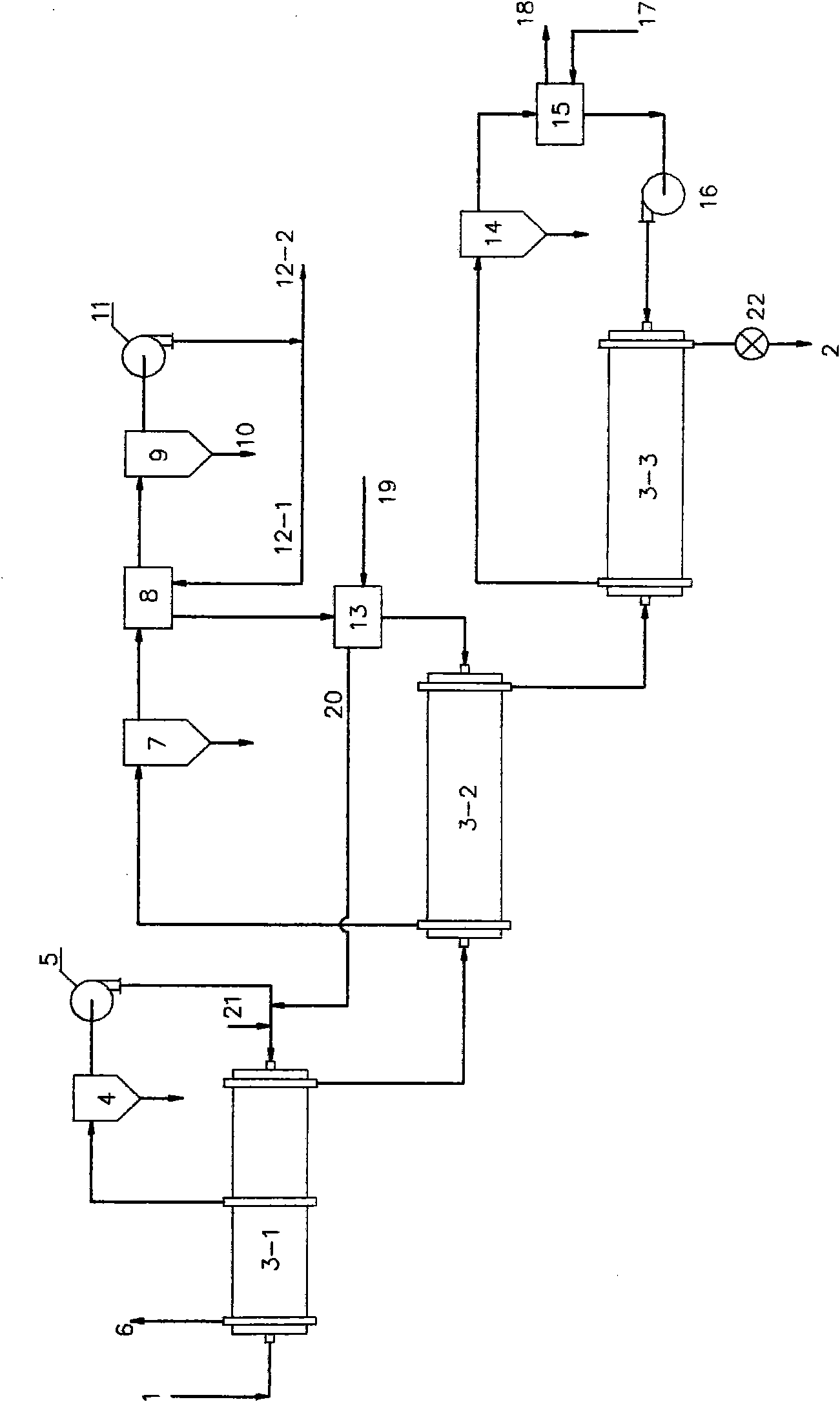

[0026] The raw material lignite (1) first enters the drying section (furnace) (3-1) of the main furnace (3), contacts with the hot flue gas entering the furnace in countercurrent, and is gradually heated to 150-300°C (for example, 150°C, 200°C, 300°C), the coal is fully dehydrated and dried, and enters the dry distillation section (furnace) (3-2) of the main furnace (3) through gas sealing, and is in countercurrent contact with the high-temperature gas entering the furnace, and continues to be heated to 400-850°C (for example 400°C, 600°C, 850°C), pyrolysis and dry distillation of coal into semi-coke, while escaping gas and tar vapor. The hot semi-coke enters the coke quenching section (furnace) (3-3) of the main furnace (3), and contacts with the self-circulating cold air (coal gas or flue gas or inert gas) medium in the furnace in countercurrent, and the semi-coke is cooled to below 160°C (Concretely subject to the fact that the semi-coke does not ignite spontaneously when e...

Embodiment 2

[0032] Taking a lignite in Indonesia as an example, industrial analysis shows that its calorific value is 3480kcal / kg, total water (MT) is 40%, air-dry basis water (Mad) is 17.5%, ash (Aad) is 2.5%, and volatile matter (Vad) is 40%. , fixed carbon (Fcad) 40%, total sulfur (St) 0.5%. After the raw coal is crushed and sieved, put the coal with a particle size in the range of 5-50mm at a rate of 500kg / h into a three-stage vertical furnace for dry distillation treatment (see attached figure 2 ), the temperature in the drying section is controlled to be 200°C, the temperature in the dry distillation section is 630°C, and the semi-coke is cooled to below 100°C in the quenching section to obtain a semi-coke product of 182kg / h (analysis of its moisture content is 5%, ash content is 5.2%, volatile content 10.5%, fixed carbon 83%). The coke quenching section is cooled by self-circulation of gas in the furnace, the temperature of the circulating gas entering the furnace is about 50°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com