Reaction apparatus for resorcinol neutralization reaction section and reaction technology thereof

A reaction device and technology of resorcinol, which are applied in the field of resorcinol neutralization reaction device, achieve the effects of high labor intensity, low cost, and avoiding the generation of solid wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

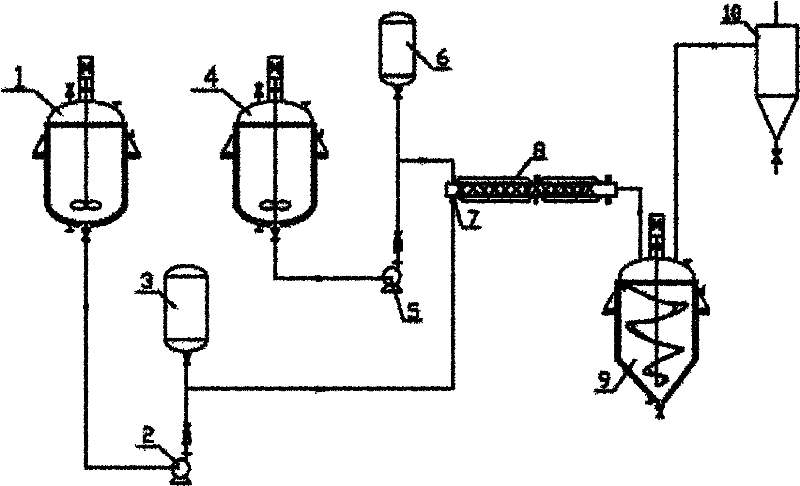

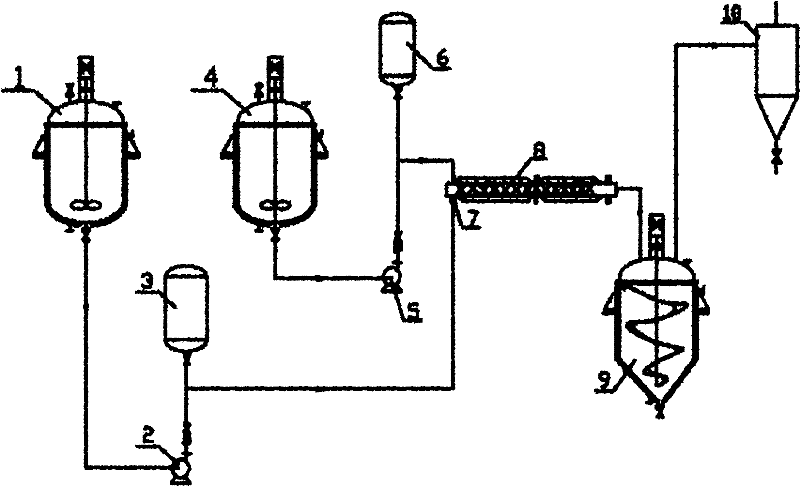

[0056] like figure 1 Shown, a kind of reaction device of resorcinol neutralization reaction section, this device comprises static mixer 8, is provided with distributing head 7 at the feeding end of static mixer 8, and described distributing head 7 has two feeding The material chamber is separated by a partition in the middle, and each cavity is connected with a feed port, one feed port is connected with the sulfonated material storage tank 1, and the other feed port is connected with the liquid alkali storage tank 4, statically mixed The other end of the device 8 is connected to the material collection tank 9, a mixing unit is arranged in the static mixer 8, and an insulating jacket is arranged outside, and the static mixer 8 is sealed.

Embodiment 2

[0058] This embodiment is the same as Embodiment 1, except that the mixing unit of the static mixer 8 is SK type, SV, SX or SL. The static mixer 8 is composed of three sections connected in series. One of the feed ports described above is connected with the damper 3, and the damper 3 is connected with the sulfonated material storage tank 1, and the other feed port is connected with the damper 6, and the damper 6 is connected with the liquid alkali storage tank 4 again; static mixing The other end of the device 8 is connected to the material collection tank 9, and the collection tank 9 is connected to the dust collector 10 again.

Embodiment 3

[0060] like figure 1 Shown, the reaction technology of the reaction device of resorcinol neutralization reaction workshop section:

[0061] (1) Delivery: the isophthalic acid and alkali are transported to the static mixer 8 through the two feed chambers of the distribution head 7, the ratio of the isophthalic acid and the alkali is 1:2.2, and the alkali 50% NaOH;

[0062] (2) Reaction: isophthalic acid and NaOH enter the airtight static mixer 8, vacuumize the jacket of the static mixer 8, and stir and react through the mixing unit in the static mixer 8;

[0063] (3) Separation: After the reaction is completed, the mixed phase of the reaction product enters the material collection tank 9 .

[0064] Use a metering pump to feed the high-temperature sulfonated material and the prepared liquid alkali in a molar ratio of 1:2.2 to the static mixer at a speed of 200L / h and feed them simultaneously. The neutralization heat of the reaction raises the temperature of the static mixer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com