Slice conveying line and conveying system using the same

A conveying line and slicing technology, which is applied in the direction of sending objects, transportation and packaging, thin material processing, etc., can solve the problems of water pollution and high labor intensity of slices, and achieve compact structure, reduce labor intensity, and reduce occupied space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

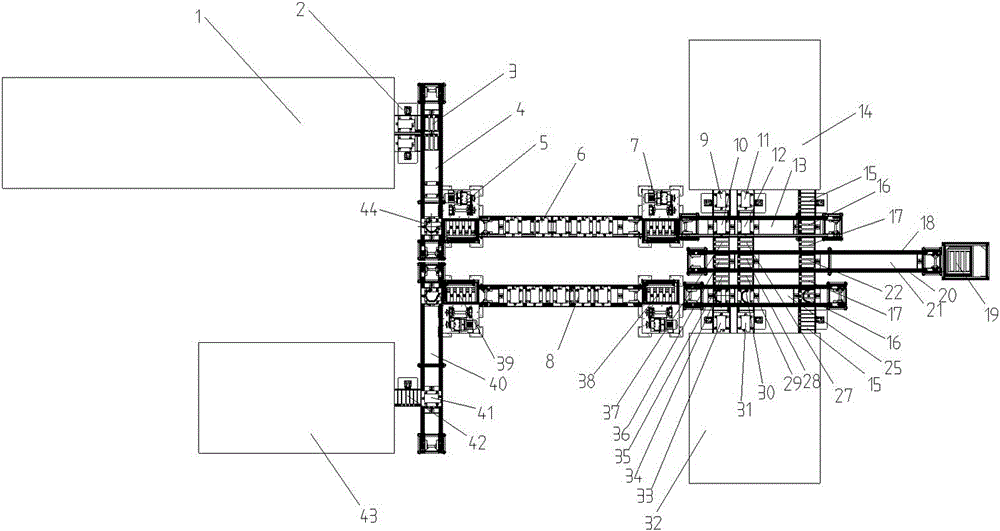

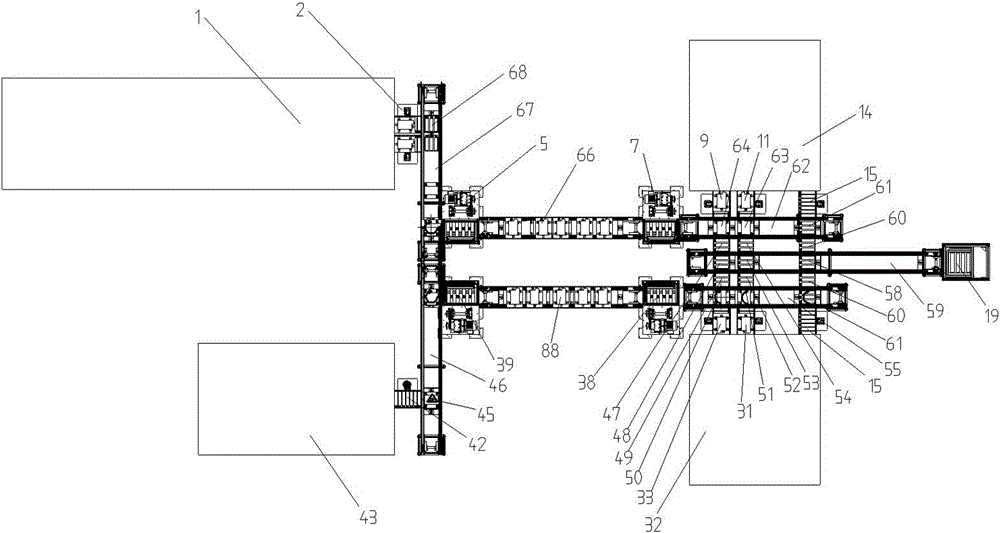

[0017] Examples of delivery systems are Figure 1~2 Shown: the conveying system includes left slicer 1, right slicer 43, left stacker 14, right stacker 32, pick-up table and conveying part, the left slicer is used to cut out positive electrode slices, and the right slicer is used for Cut out the negative electrode slices, the left and right stacking machines are used to stack the positive and negative electrode slices into batteries, and the conveying part is used to transport the positive and negative electrode slices to the corresponding stacking machine, and transport the batteries to the reclaiming table. The stacking tray is transported back to the corresponding stacking machine, the slice tray loaded with slices is transported to the corresponding stacking machine, and then the empty slice tray is transported back to the corresponding slicer. In order to save space, the conveying part in the present invention is divided into an upper conveying part and a lower conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com