A lost foam casting method

A lost foam and sand box technology, applied in the field of foundry modeling, can solve the problems of insufficient compactness and low compliance rate of castings, and achieve the effects of high compactness, improved compliance rate and guaranteed integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

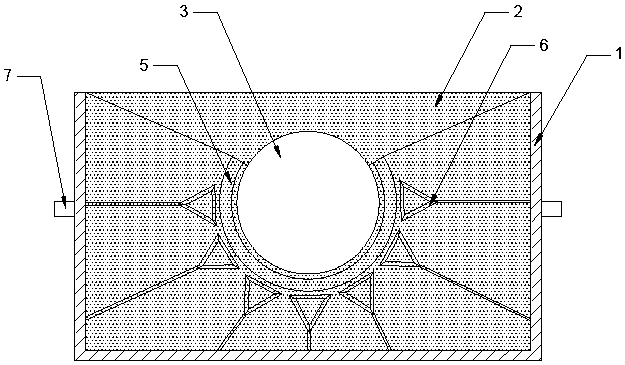

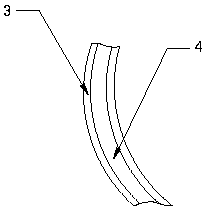

[0014] The reference signs in the drawings of the description include: sand box 1 , molding sand 2 , body 3 , rope groove 4 , sand bag 5 , expansion block 6 , and hanging ring 7 .

[0015] The embodiment is basically as attached figure 1 , figure 2 Shown: a lost foam casting device used in a lost foam casting method, including a sand box 1, molding sand 2 and an elevator sheave-like lost foam, the molding sand 2 is filled with the sand box 1, the lost foam is placed inside the molding sand 2, and the sand The box 1 is connected with a filling layer matching the rope groove 4 through an iron chain. The filling layer includes a sand layer and a sand bag 5 in turn from the inside to the outside. There are several sets of preheated expansion blocks 6 inside the molding sand 2. Each set The expansion blocks 6 are arranged opposite to the sandbags 5, and a support rod is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com