Peanut screw conveying method of peanut picker

A peanut picking machine and peanut fruit technology, which is applied to harvesters, digging harvesters, agricultural machinery and implements, etc., can solve the problems of easy jamming of conveyor belts, unfavorable peanut picking efficiency, and high peanut fruit content, and achieve The effect of high conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

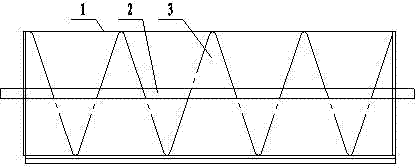

[0013] As shown in the figure, it is a spiral peanut fruit conveying method for a peanut fruit picking machine, in which the spiral sheet 3 is wound and welded on the main shaft 2 in a spiral form, and the outer cylinder 1 is set outside the spiral sheet 3 .

[0014] A method for conveying peanuts with a screw for a peanut picking machine, comprising:

[0015] The main shaft drives the helical piece to rotate: the main shaft 2 rotates under the drive of the power system, and then drives the helical piece 3 to rotate in the outer cylinder 1;

[0016] Transportation of peanuts: Peanuts transported from the threshing mechanism of the combined peanut threshing machine enter the outer cylinder 1 and are pushed forward by the helically rotating spiral piece 3 until they are transported to the air delivery mechanism for peanut collection and loading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com