Low-energy-consumption preparation method for preparing argon and nitrogen gases

A technology with low energy consumption and gas, which is applied in the field of preparation of argon and nitrogen gas with low energy consumption. It can solve the problems of cumbersome methods, high cost, and inability to meet high purity, and achieve the effect of low energy consumption and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

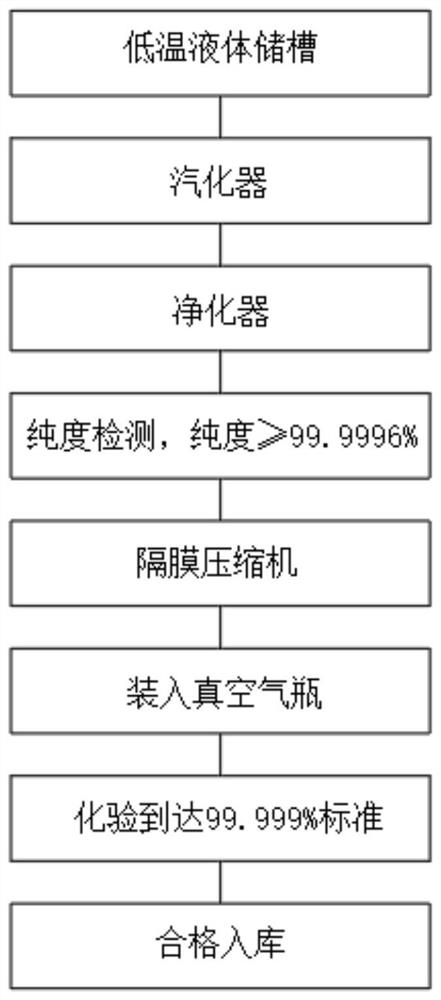

[0023] A method for preparing argon and nitrogen gas with low energy consumption, comprising the following steps:

[0024] 1) Send the liquid in the low-temperature liquid storage tank with a purity of 99.99% to the vaporizer for gasification, and the vaporized gas is purified in the purifier; the liquid is one of liquid argon or liquid nitrogen;

[0025] 2) The gas processed by the purifier passes through the impurity remover and then undergoes a purity test. After the purity test is qualified, the gas is sent to a diaphragm compressor, pressurized at 0mpa-15mpa, and loaded into a vacuum bottle. The shell of the impurity remover A composite membrane is provided in the body, the separation membrane includes a base membrane and an effective separation layer, the effective separation layer is a copolymer of tetrafluoroethylene and a perfluorinated solvent, the thickness of the effective separation layer is 0.1-0.5 μm, and the The base film includes 6-12 parts of polyethylene gly...

Embodiment 1

[0036] 1) Send the liquid in the low-temperature liquid storage tank with a purity of 99.99% to the vaporizer for gasification, and the vaporized gas is purified in the purifier; the liquid is one of liquid argon or liquid nitrogen;

[0037] 2) The gas processed by the purifier passes through the impurity remover and then undergoes a purity test. After the purity test is qualified, the gas is sent to a diaphragm compressor, pressurized at 0mpa-15mpa, and loaded into a vacuum bottle. The shell of the impurity remover A composite membrane is provided in the body, the separation membrane includes a base membrane and an effective separation layer, the effective separation layer is a copolymer of tetrafluoroethylene and a perfluorinated solvent, the thickness of the effective separation layer is 0.1-0.5 μm, and the The base film includes 12 parts of polyethylene glycol, 70 parts of polyethylene resin, 7 parts of dispersant, 6 parts of nano-silicon carbide, 8 parts of nanofiber, 6 pa...

Embodiment 2

[0051] 1) Send the liquid in the low-temperature liquid storage tank with a purity of 99.99% to the vaporizer for gasification, and the vaporized gas is purified in the purifier; the liquid is one of liquid argon or liquid nitrogen;

[0052] 2) The gas processed by the purifier passes through the impurity remover and then undergoes a purity test. After the purity test is qualified, the gas is sent to a diaphragm compressor, pressurized at 0mpa-15mpa, and loaded into a vacuum bottle. The shell of the impurity remover A composite membrane is provided in the body, the separation membrane includes a base membrane and an effective separation layer, the effective separation layer is a copolymer of tetrafluoroethylene and a perfluorinated solvent, the thickness of the effective separation layer is 0.1-0.5 μm, and the The base film includes 6 parts of polyethylene glycol, 50 parts of polyethylene resin, 3 parts of dispersant, 4 parts of nano-silicon carbide, 3 parts of nanofiber, 3 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com