A rapid forging and hot cutting production system and its working method

A production system and working method technology, applied in the direction of operating devices, manufacturing tools, metal processing equipment, etc., can solve the problems of processing quality impact, product impact, burr easy growth, etc., to achieve low scrap rate, reduce labor costs, purity stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

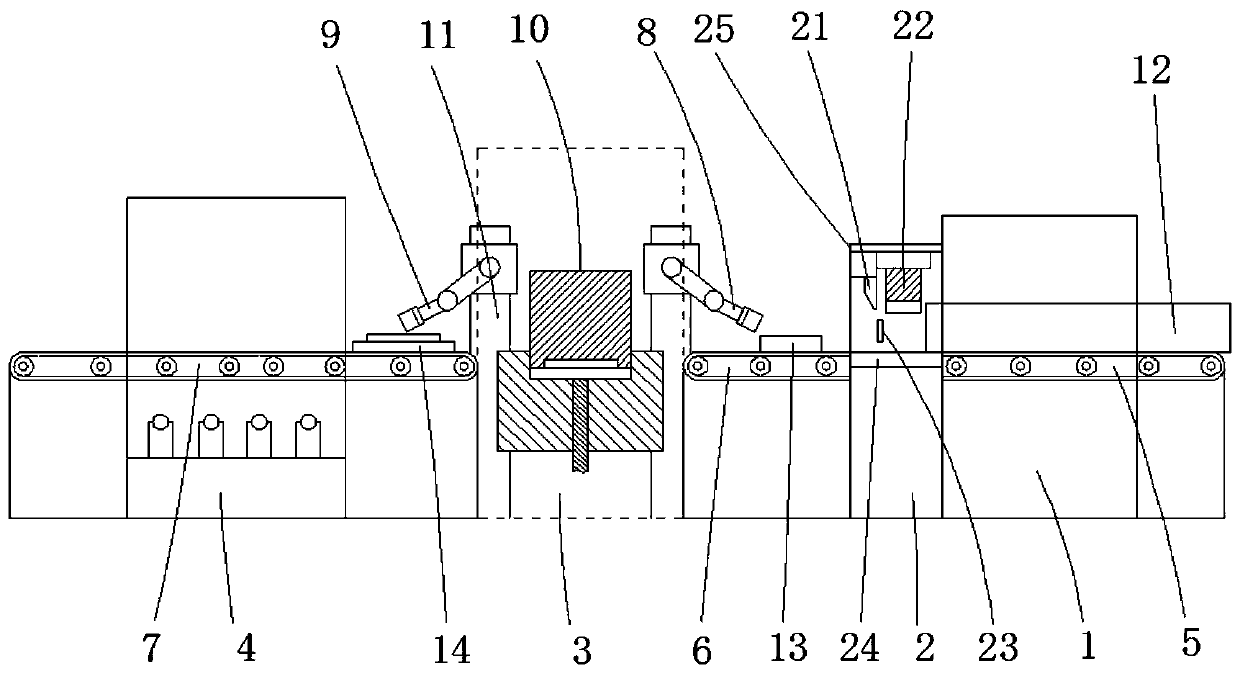

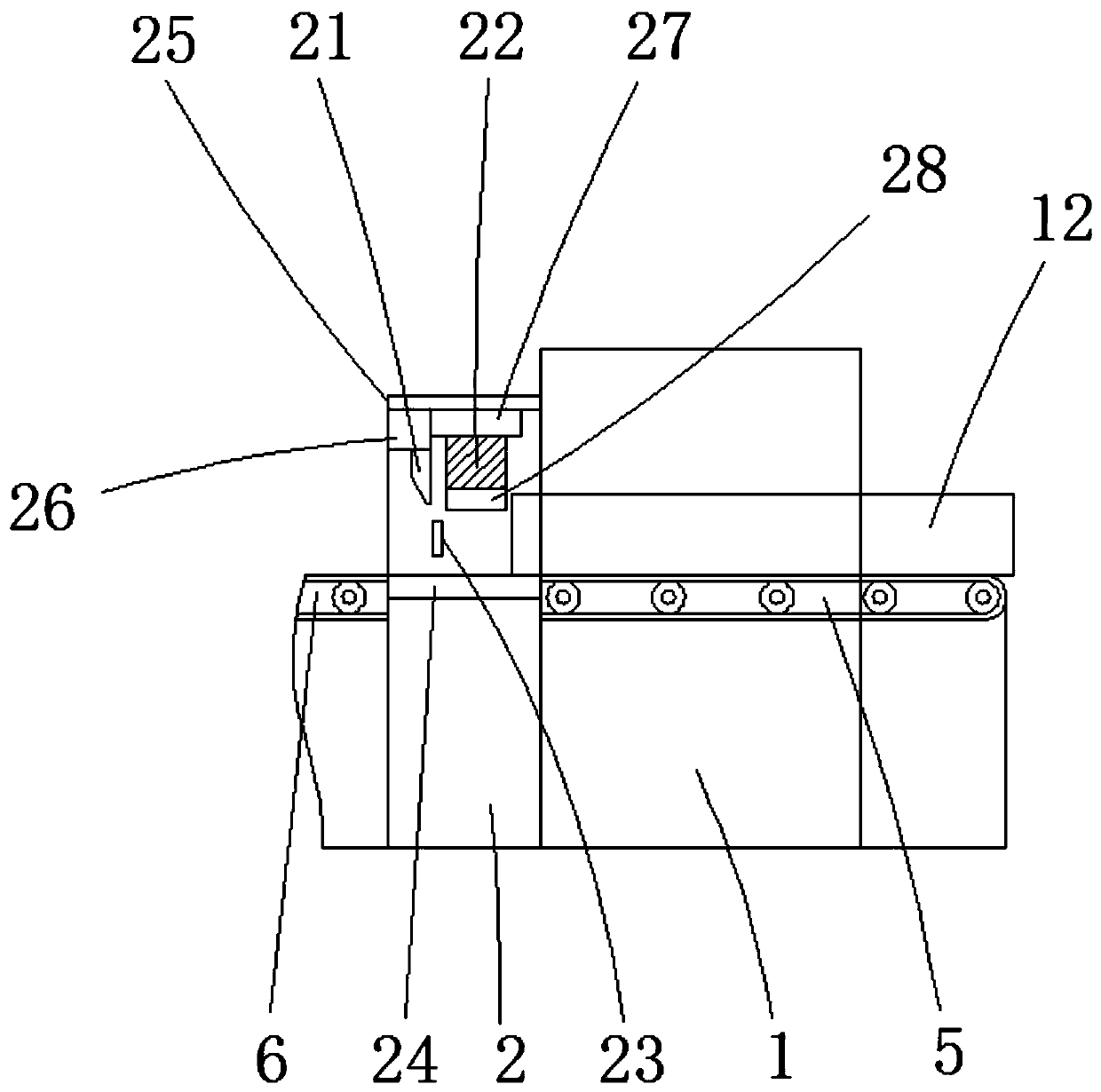

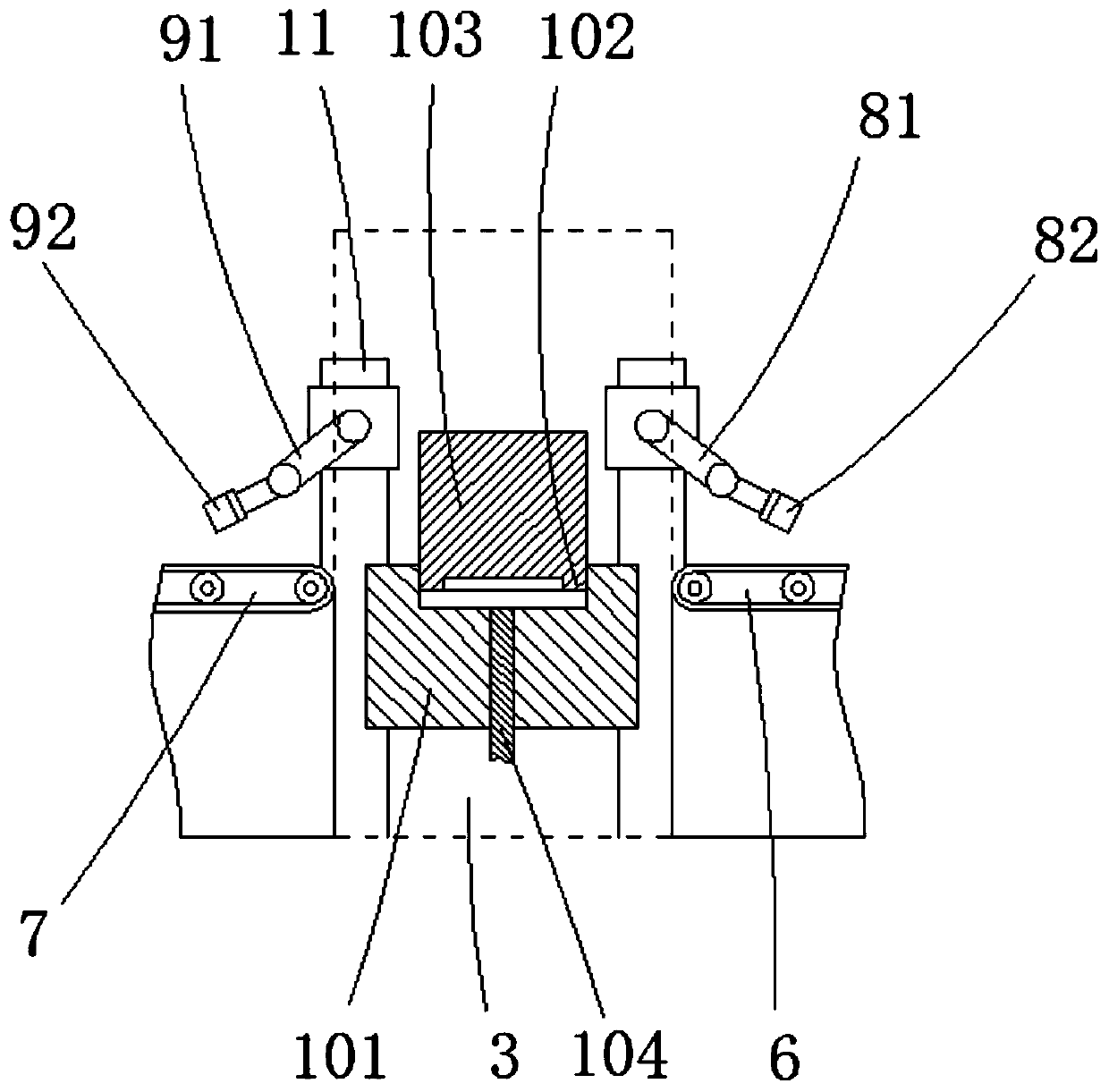

[0028] A kind of rapid forging hot cutting production system of the present invention, such as Figure 1 to Figure 3 As shown, it includes a heating device 1, a hot cutting device 2, a forging device 3 and a heat treatment device 4 arranged in sequence; , the hot-cutting device 2 is connected with the heating furnace of the heating device 1, and an insulating sleeve 25 is arranged above the hot-cutting workbench 24, and the cutting knife 21 and the pressing mechanism 22 are arranged inside the insulating sleeve 25; The material pushing device 23 is arranged on one side in the middle of the cutting knife 21 and the pressing mechanism 22, and is connected with a telescopic device and a turning device; the cutting knife 21 is connected with a cutting driving device 26, and the pressing mechanism 22 A pressing device 27 is connected, and the pressing device 27 drives the pressing mechanism 22 to press the raw material rod 12 through a cylinder or an oil cylinder. The end of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com