Nitrogen adjusting device for semiconductor oven

An adjustment device and semiconductor technology, applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problems of reducing the internal temperature of the oven, the poor effect of semiconductor drying, and reducing the drying quality of the oven, so as to improve the drying efficiency. Effect, anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

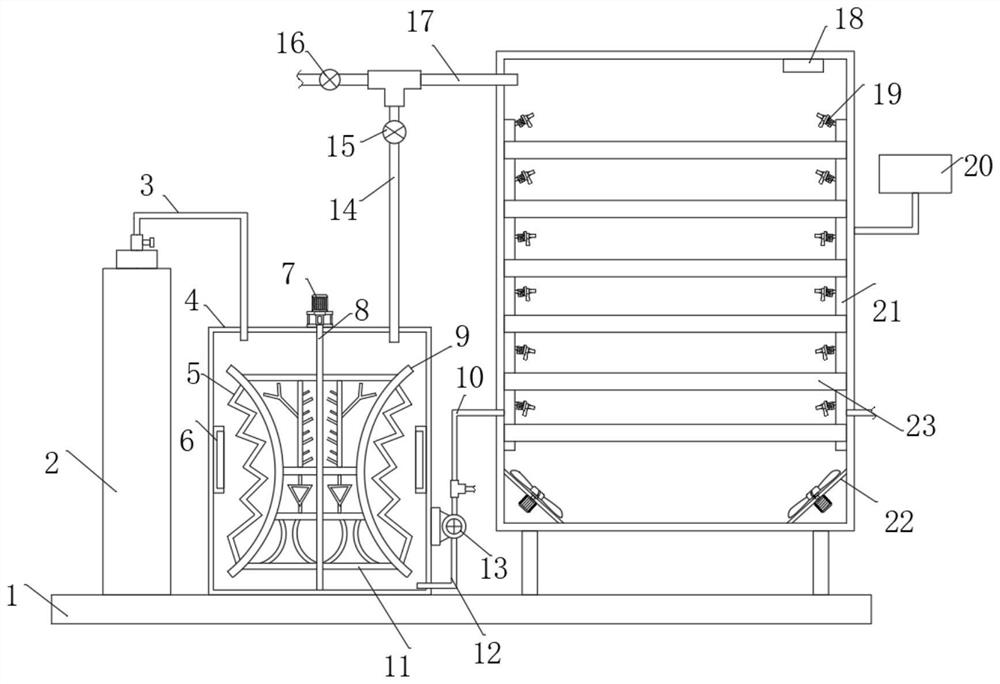

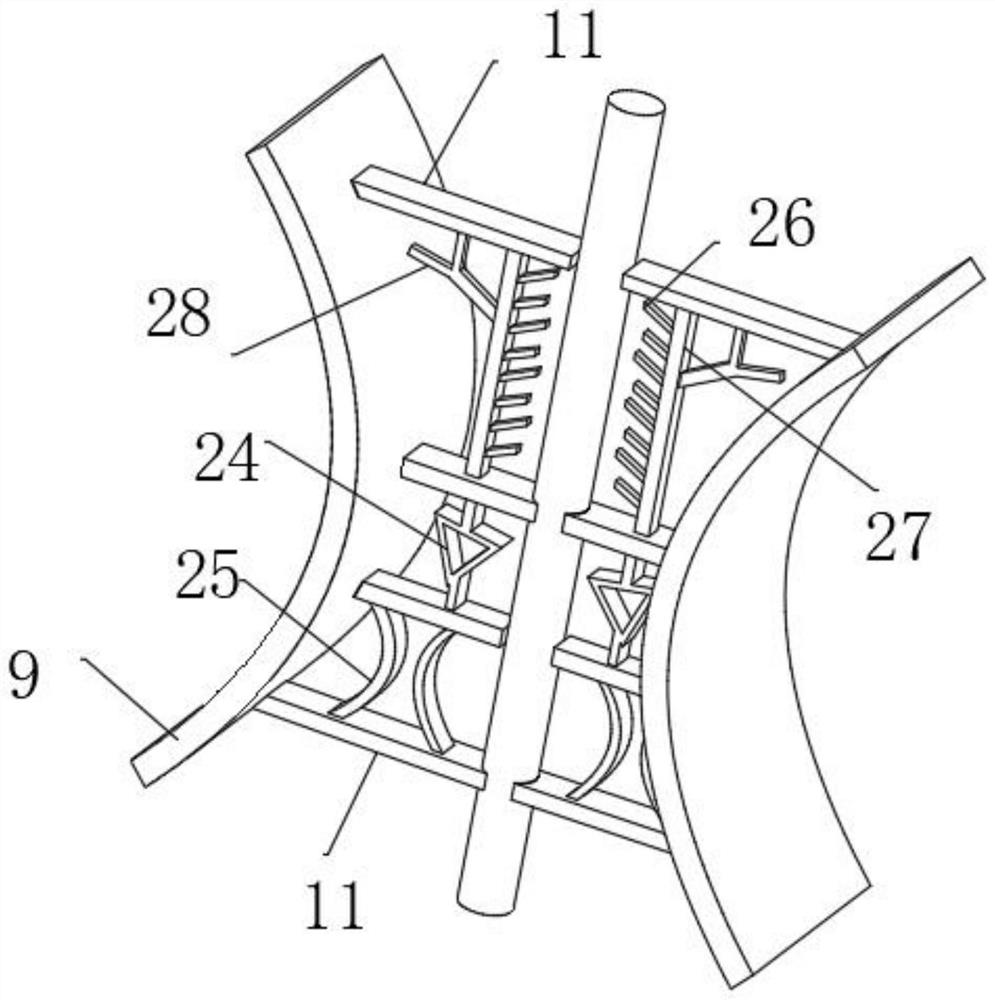

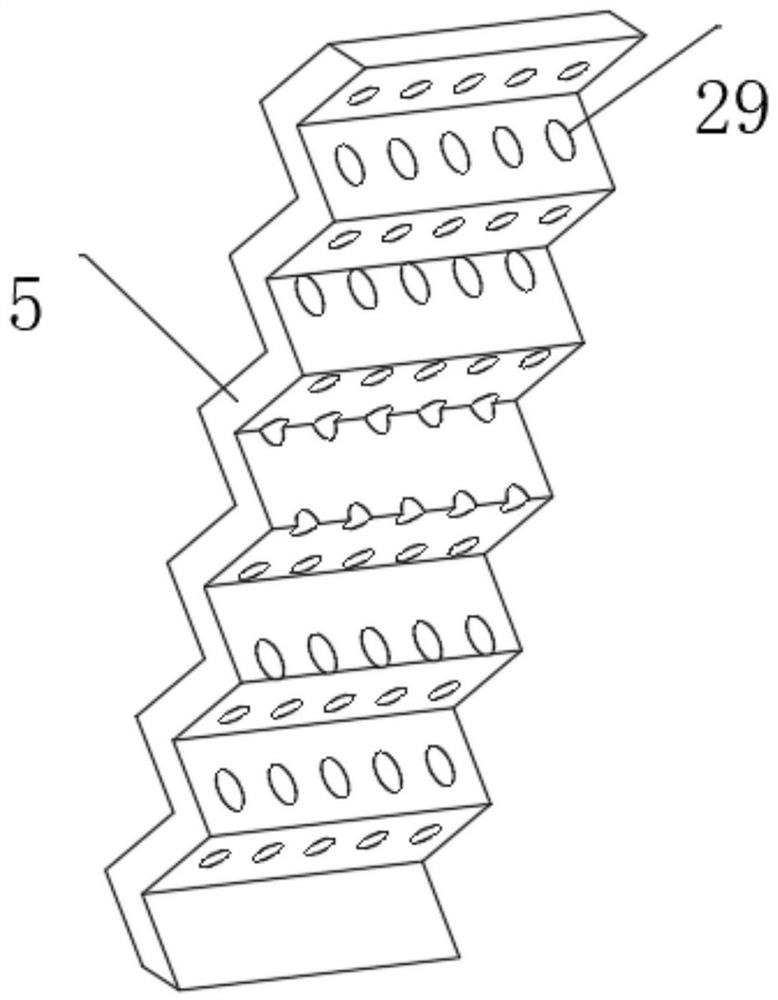

[0030] refer to Figure 1-4 , a semiconductor oven nitrogen regulating device, comprising a bottom plate 1, the top outer wall of the bottom plate 1 is provided with a nitrogen bottle 2, a heating box 4 and a drying box, and one side of the outer wall of the heating box 4 is fixed with an electronic air pump 13 by screws, and the electronic air pump The input end of 13 and the inner wall of one side of the heating box 4 are connected with the same third guide roller 12 through the flange, and the output end of the nitrogen cylinder 2 and the top inner wall of the heating box 4 are connected with the same first conduit 3 through the flange. And both sides of the inner wall of the heating box 4 are fixed with a heater 6 by screws, and the both sides of the inner wall of the drying box are fixed with an air jet disc 21 by screws, and one side of the outer wall of the air jet disc 21 is fixed with spray nozzles distributed equidistantly by screws. 19. The inclination angles of the...

Embodiment 2

[0038] refer to Figure 5 , a nitrogen regulating device for a semiconductor oven. Compared with Embodiment 1, this embodiment also includes a choke box 33 fixed to the inner wall of one side of the drying box by screws, and the top outer wall and the bottom outer wall of the choke box 33 are respectively provided with The air outlets 32 and the air inlets 31 are equidistantly distributed, and the inner wall of the choke box 33 is provided with equidistantly distributed choke passages 34 , and the choke passages 34 have a zigzag structure.

[0039] Connect the equipment to the power supply. First, open the nitrogen bottle 2 to introduce nitrogen gas into the heating box 4 through the first conduit 3, turn on the heater 6 and the motor 7, and the motor 7 drives the rotating rod 8 to rotate, and then the first stirring rod 9, the horizontal The rod 11, the stirring frame 24 and the arc rod 25 can evenly heat the nitrogen gas, turn on the electronic air pump 13, and introduce the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com