Cleaning and drying device for textile products

A drying device and textile technology, applied in the field of cleaning and drying devices for textile products, can solve the problems of inability to spin dry and drain water, inconvenient recycling of water vapor, and discharge into the atmosphere, so as to improve the cleaning effect and ensure the accuracy , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

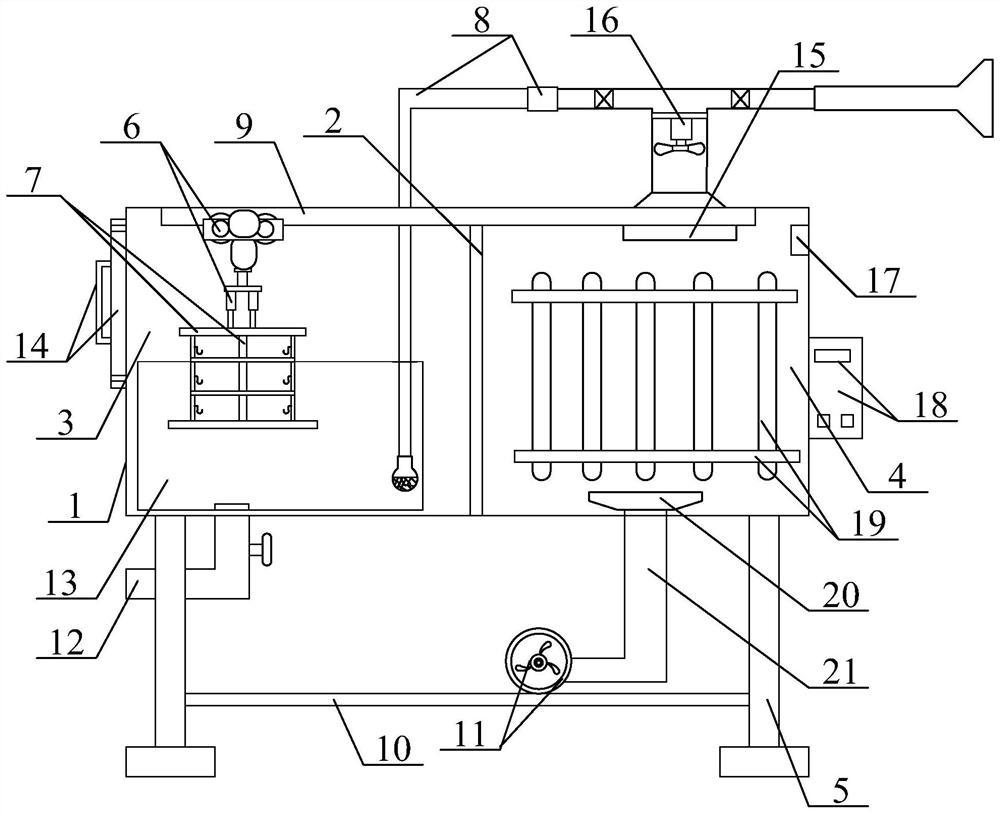

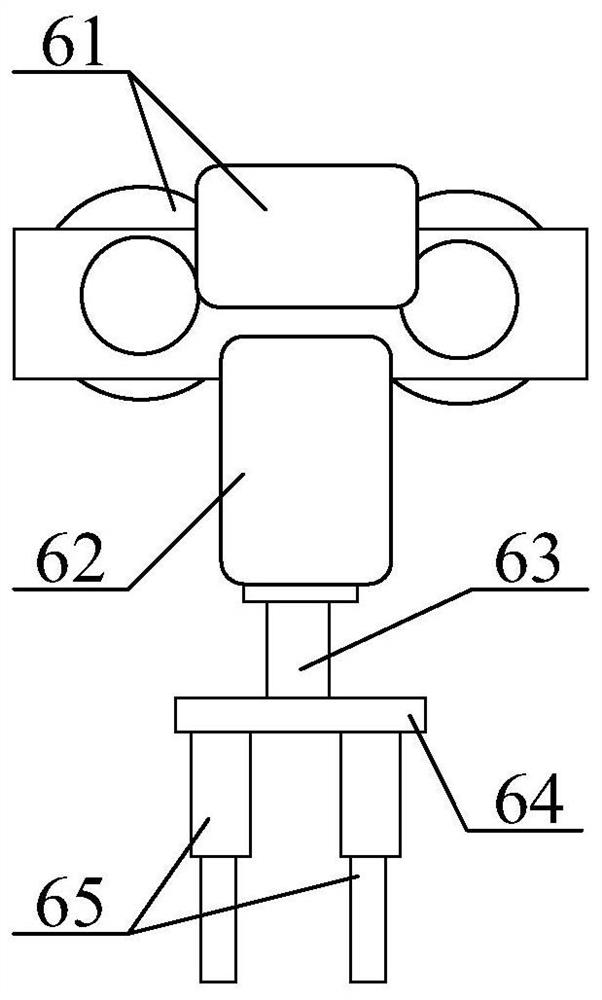

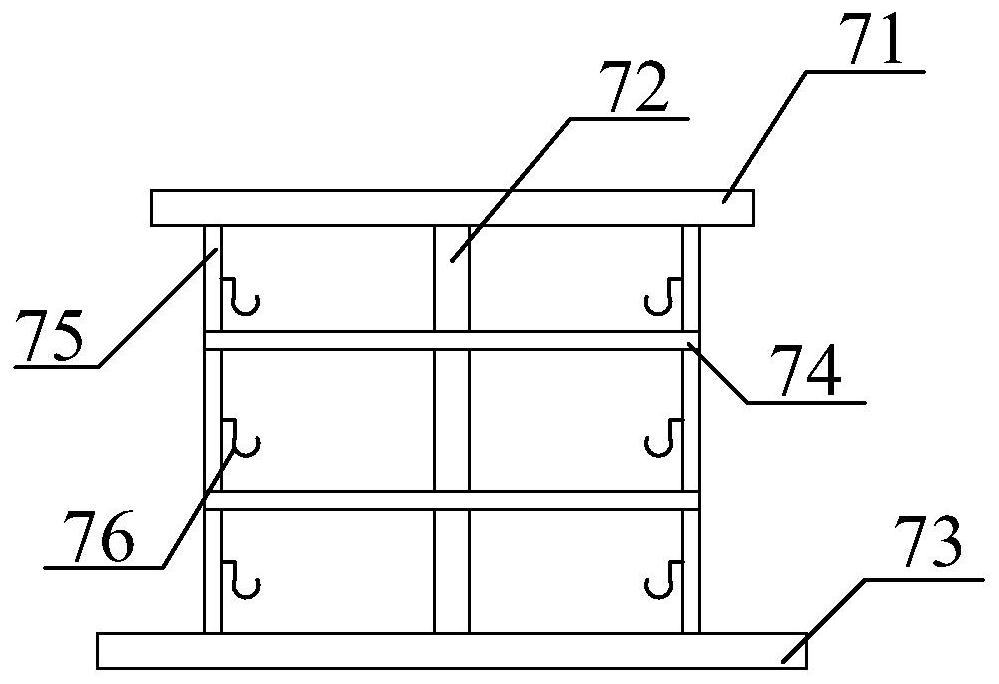

[0035] as attached figure 1 to attach Figure 5 As shown, the present invention provides a cleaning and drying device for textile products, including a cleaning and drying integrated box 1, an electric door 2, a cleaning room 3, a drying room 4, a support column 5, and an immersion cleaning driving hanging plate assembly 6. Textile fixing frame assembly 7, steam diversion conduit assembly 8, rail 9, cross support plate 10, blower 11, waste pipe 12, cleaning box 13, manual door 14, air collecting hood 15, exhaust fan 16, temperature sensor 17, control box 18, electric heating pipe 19, air outlet cover 20 and air guide pipe 21,

[0036] The electric door 2 is longitudinally embedded in the middle of the integrated cleaning and drying box 1; the integrated cleaning and drying box 1 is divided into a cleaning room 3 and a drying room 4 under the action of the electric door 2; the supporting Columns 5 are respectively bolted to the lower four corners of the cleaning and drying in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com