Environment-friendly automatic rivet nut cleaning system

A technology for automatic cleaning and riveting of nuts, applied in cleaning methods and utensils, cleaning methods using liquids, dryers, etc., can solve the problems of inability to reuse, waste, and troublesome operation of cleaning liquids, and achieve a high degree of automation. , the effect of saving labor and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

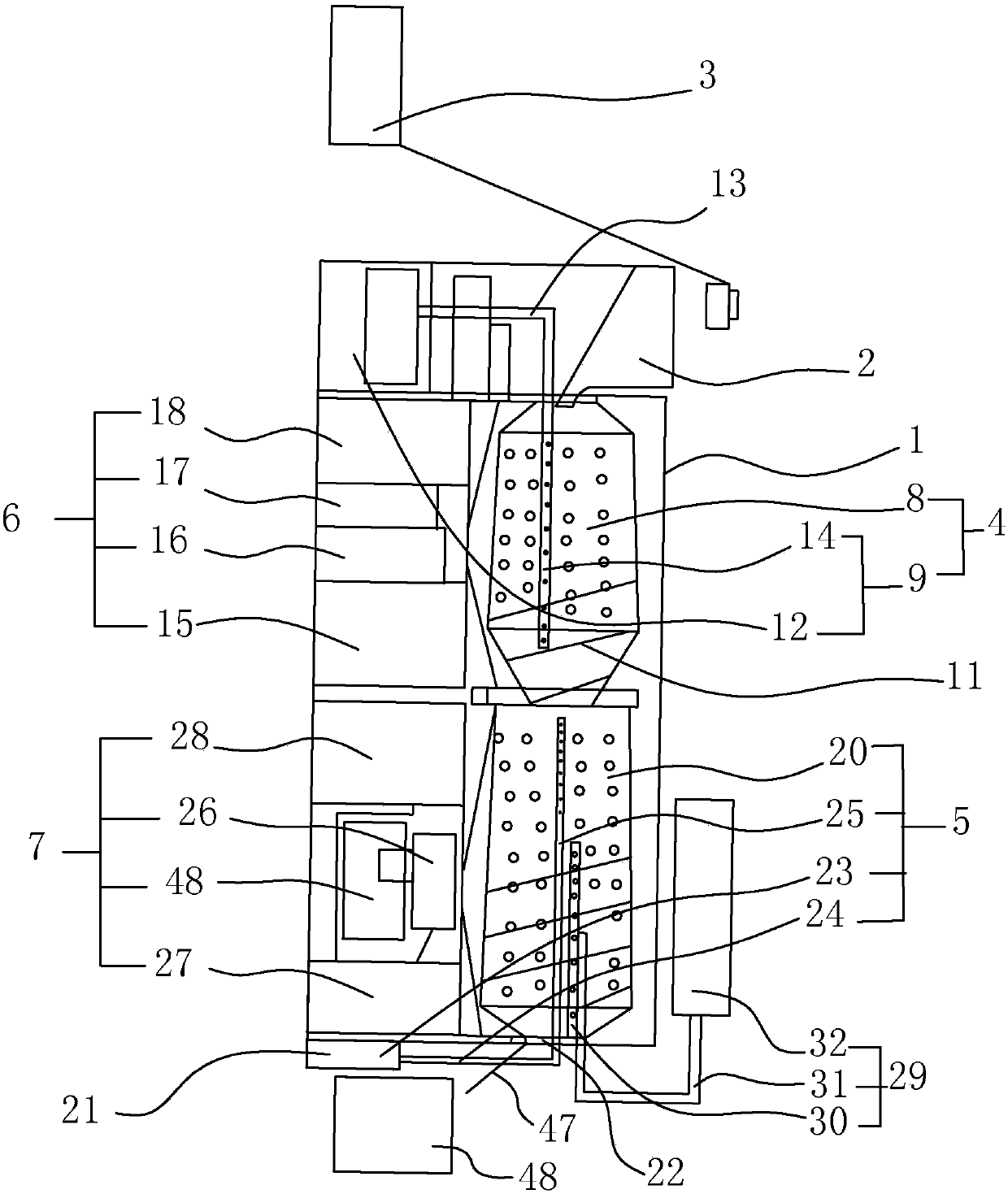

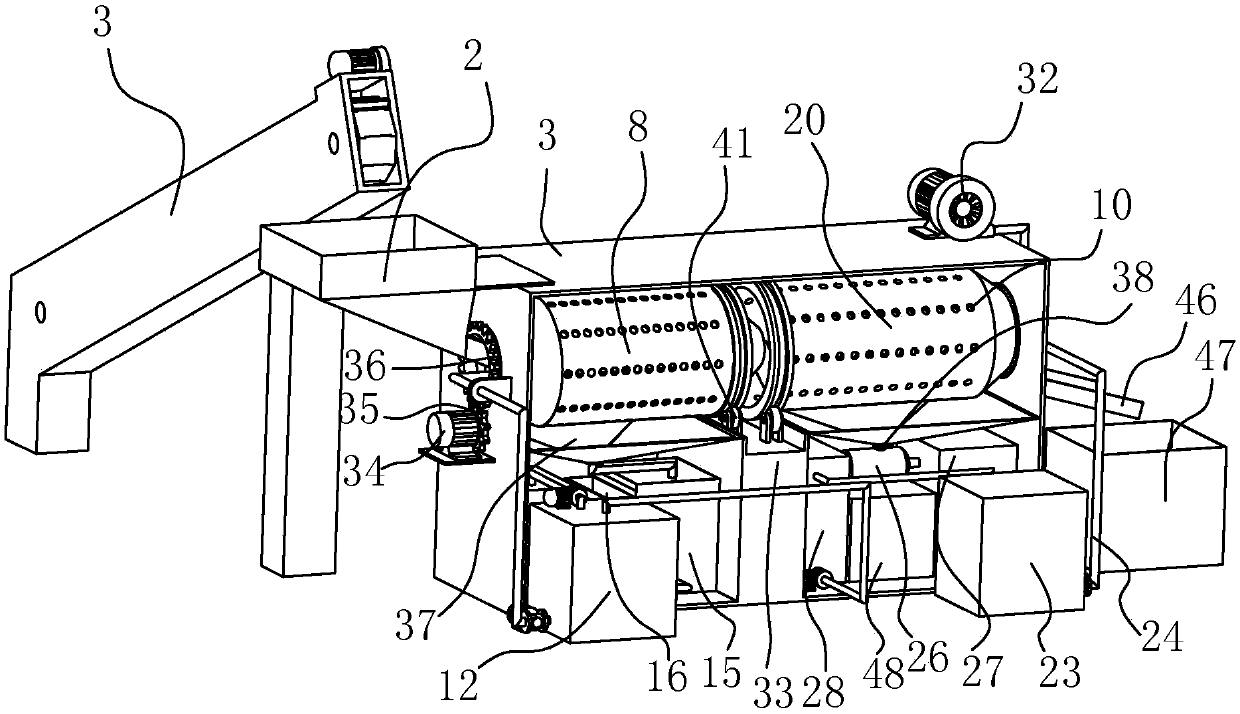

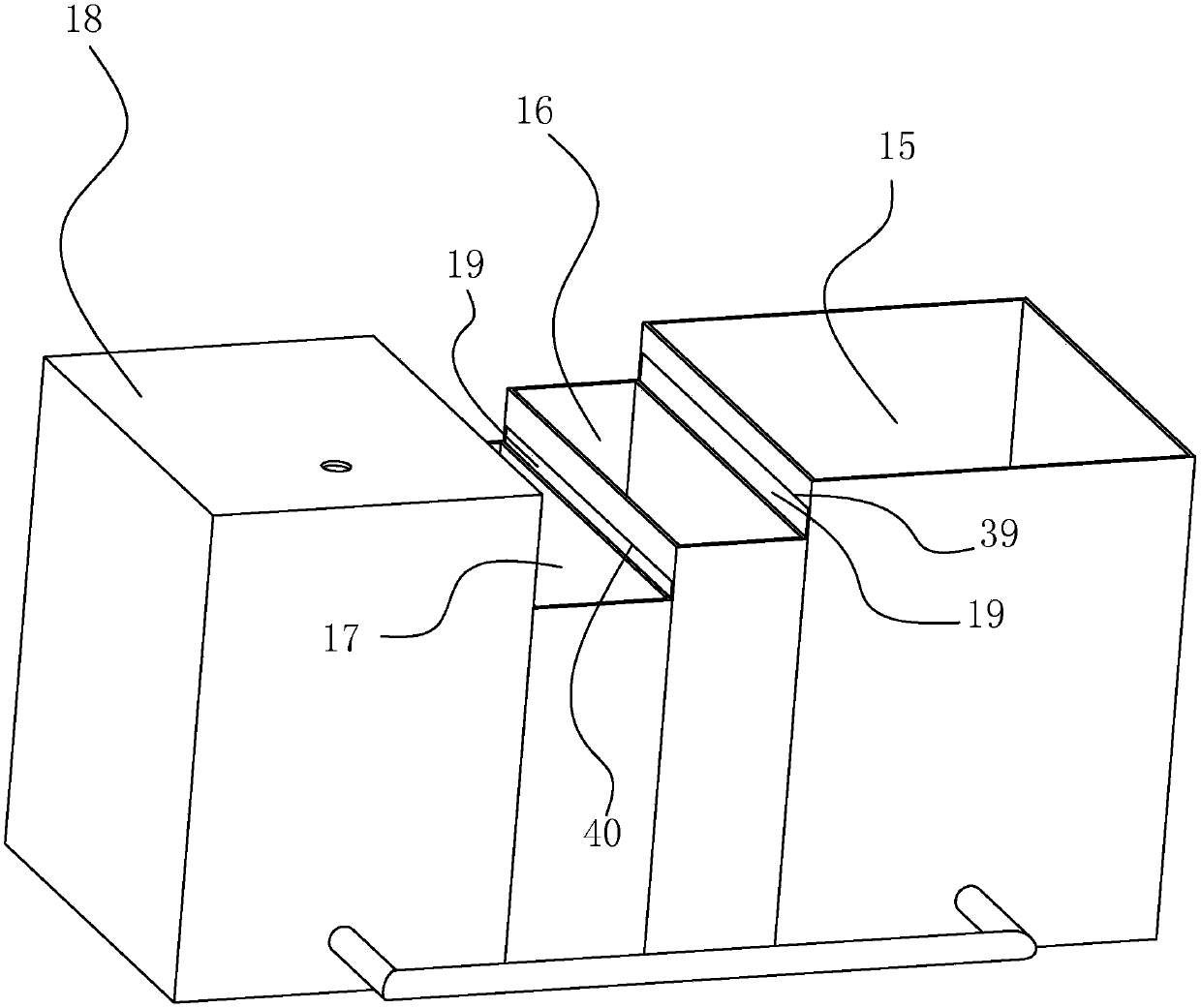

[0035] An environment-friendly automatic cleaning system for rivet nuts, such as figure 1 As shown, it includes a cleaning box 1, the cleaning box 1 is a box structure, a feeding hopper 2 is connected to the upper end of the cleaning box 1, and a feeding mechanism 3 is also included. The feeding mechanism 3 can adopt a common chain plate hoist on the market. The upper end of the chain plate elevator is located above the feeding hopper 2, and the workpieces such as rivet nuts are transported upwards to the feeding hopper 2 through the chain plate elevator, and enter the cleaning box 1 through the feeding hopper 2; A first cleaning mechanism 4 connected to the feed hopper 2 and a second cleaning mechanism 5 communicating with the first cleaning mechanism 4 are provided. Below the first cleaning mechanism 4, a cleaning solution for flowing out of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com